Product Categories

Explore our comprehensive range of industrial automation products categorized for easy navigation. Find the right solutions for your specific needs.

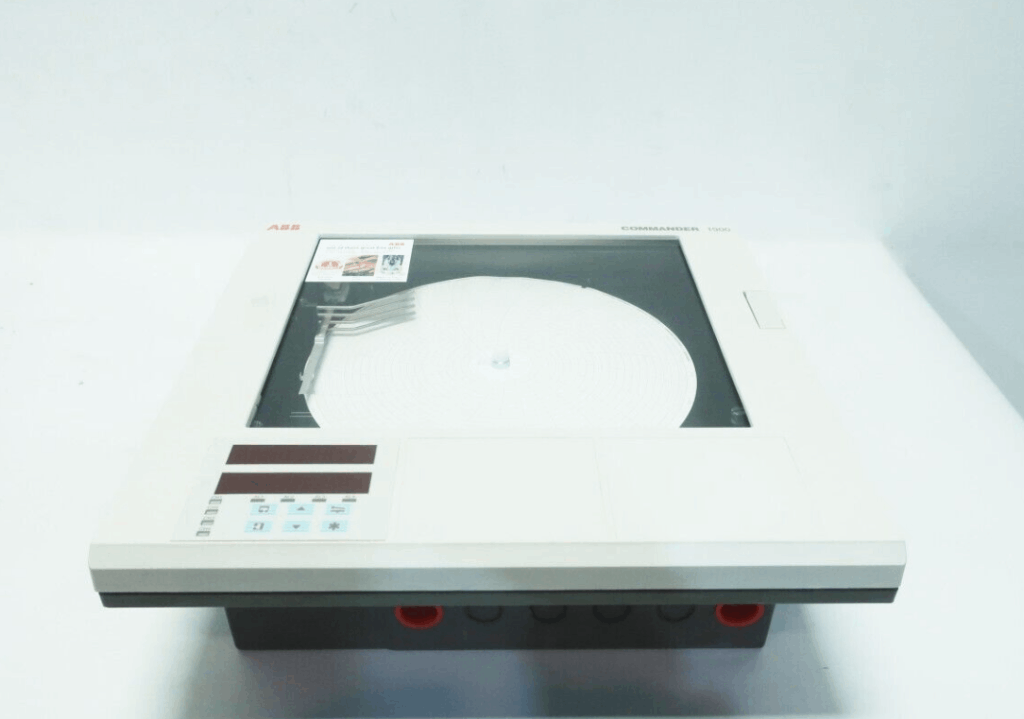

ABB 1912JA001100000 COMMANDER 1900 Chart recorder

The ABB 1912JA001100000 COMMANDER 1900 CHART RECORDER represents a state-of-the-art device designed for accurate and deta

ABB 1MRK000008-LBr02 Front Display Panel

The ABB 1MRK000008-LBR02 is a front display panel tailored for the RET670 series protective relays. Operators use it for

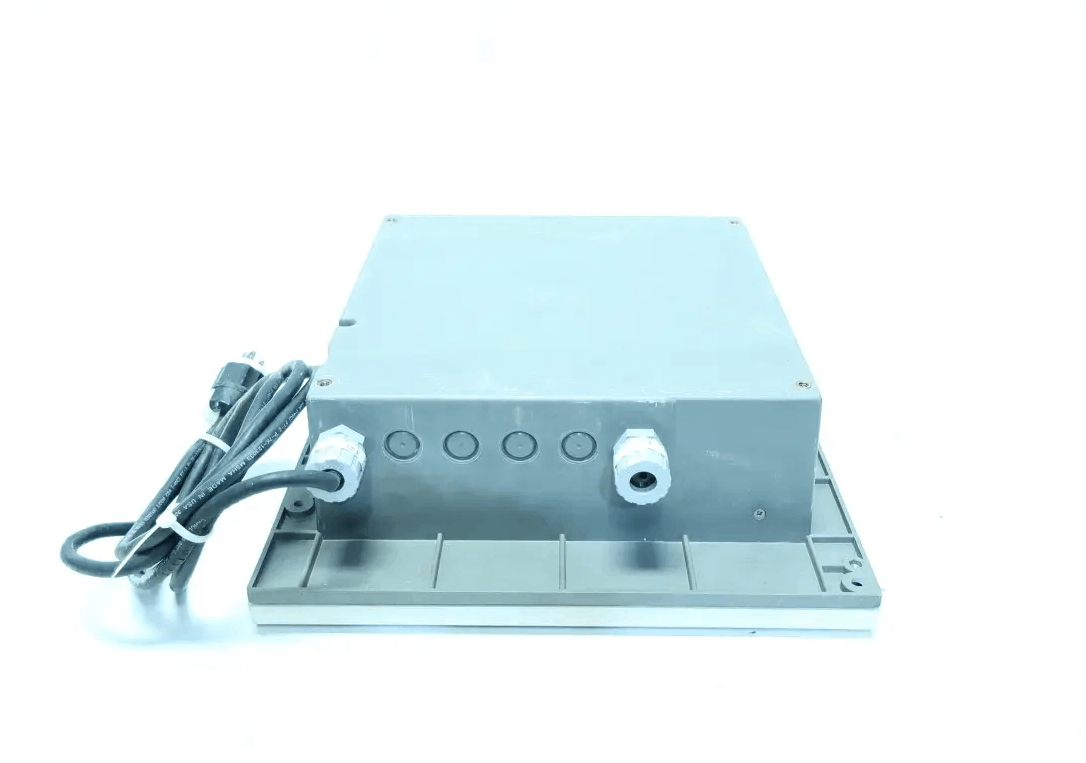

ABB IM/C1900-RED PAK Circular chart recorder

The ABB IM/C1900-RED PAK Circular Chart Recorder stands out as an exceptional product, renowned for its reliable service

ABB 1KHL178012R0001M Display Unit

The ABB 1KHL178012R0001M is a display unit designed to work with ABB protection relays, such as the REC650 and REB650 ser

ABB 1MRK000008-MB REC670 BCU Display

The ABB 1MRK000008-MB is a robust industrial display. It seamlessly integrates into ABB’s automation systems. This disp

GE Fanuc A02B-0200-C061/TBR LCD/MDI Displays

The GE Fanuc A02B-0200-C061/TBR is a versatile 9.5-inch color LCD/MDI unit, designed to serve as a human-machine interfac

GE PQMII-T20-C-A Power Quality Meter

The PQM II is an ideal choice when continuous monitoring of a three phase system is required. It provides metering for cu

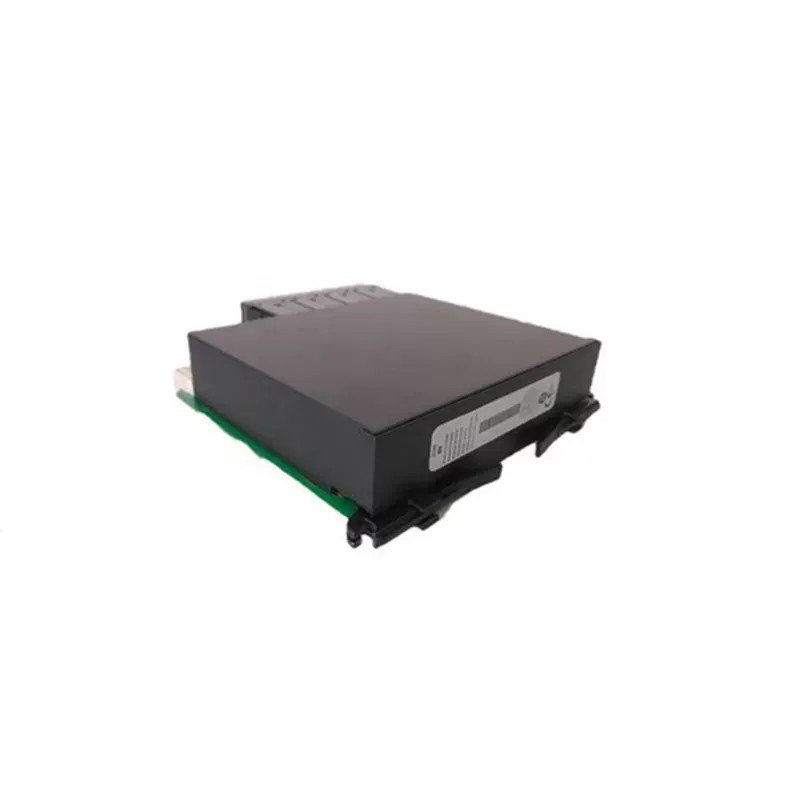

ABB SS/C1900R Circular Chart Recorder

The ABB SS/C1900R is a circular chart recorder designed for industrial process monitoring and control. It captures and re

GE Fanuc A61L-0001-0093 CRT Display

The GE Fanuc A61L-0001-0093 is a 9-inch monochrome CRT display primarily used in CNC systems. It provides operators with

ABB 1MRK000008-MBr03 Display

The ABB 1MRK000008-MBr03 is a Human-Machine Interface (HMI) display designed for industrial automation systems. It provid

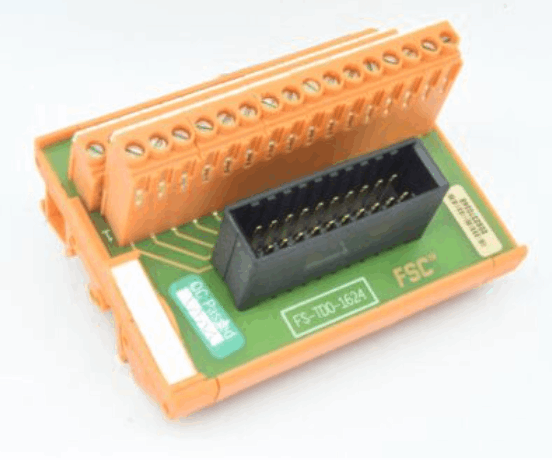

Honeywell FC-TSDI-1624C Printer Interface Board

Honeywell FC-TSDI-1624C Printer Interface Board is a high-quality product that guarantees exceptional performance and rel

B&R 5AP920.1505-01 TFT Display Screen

The BR (BR 5AP920.05-01 touch screen is widely used in multiple industries and application scenarios, including but not l

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.