Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

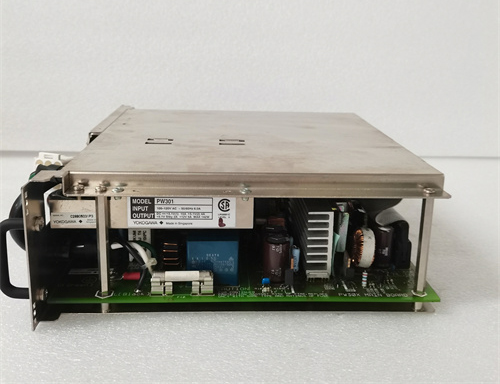

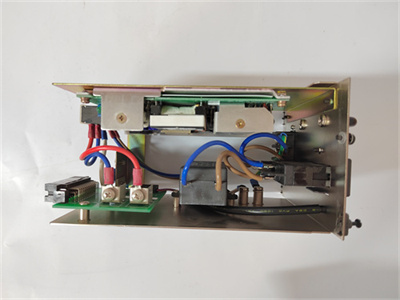

Yokogawa ANS20 Node Interface Unit

Manufacturer:Yokogawa

Product Number:ANS20

Product Type:Node Interface Unit

Origin:Japan

Dimensions:30 × 130 × 100 mm

Weight:0.36 kg

Views:87

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa ANS20 Node Interface Unit is an essential component of the ProSafe-RS safety instrumented system, functioning as a critical interface between subsystems and the main safety control units. It is specifically designed to manage redundant communication and ensure robust data transfer over the safety control network, contributing to safe, efficient, and fail-proof plant operation.

As part of Yokogawa’s modular safety platform, the ANS20 provides a reliable communication link between distributed input/output (I/O) nodes and the central controller (AFV10D CPU), enabling high-integrity, SIL-rated communication even under harsh industrial conditions. Its compact design and integration with Yokogawa’s ER Bus (Extension Redundant Bus) allow for simplified installation, scalability, and system diagnostics.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | ANS20 |

| Product Type | Node Interface Unit |

| System Platform | Yokogawa ProSafe-RS |

| Communication Bus | ER Bus (Extension Redundant Bus) |

| Redundancy | Supported (Dual path redundancy) |

| Power Supply Voltage | 24 VDC nominal (supplied via baseplate) |

| Power Consumption | Approx. 120–160 mA |

| Input/Output Channels | Acts as gateway for multiple I/O modules |

| Communication Speed | Up to 1 Mbps |

| Mounting Type | DIN Rail Mountable |

| Operating Temperature | 0°C to +55°C (32°F to 131°F) |

| Storage Temperature | -20°C to +70°C (-4°F to 158°F) |

| Humidity Tolerance | 5% to 95% RH, non-condensing |

| Ingress Protection | IP30 (when installed in cabinet) |

| Certifications | SIL3 (IEC 61508), CE, ATEX, FM, CSA |

| Firmware Upgradeable | Yes (via engineering tool) |

| Diagnostics | Built-in diagnostics and status LEDs |

| Dimensions (W × H × D) | 30 × 130 × 100 mm |

| Weight | 0.36 kg |

Product Applications

The ANS20 Node Interface Unit is primarily used in distributed safety control environments, enabling safe communication across multiple I/O nodes. Its robust design and SIL3 certification make it ideal for:

Emergency Shutdown Systems (ESD)

Allows for high-integrity safety operations across distributed plant areas.

Fire & Gas Systems (FGS)

Ensures reliable transmission of alarm and sensor signals to the central controller.

Burner Management Systems (BMS)

Facilitates safe operation and shutdown of combustion systems.

Pipeline Safety Systems

Used in oil & gas pipelines to manage safety barriers remotely.

Offshore Platforms & FPSOs

Designed for safety systems where distributed topology is critical.

Power Generation Facilities

Ensures safe and synchronized communication for turbine or boiler protection systems.

Product Advantages

Redundant Communication Support

Ensures continuous operation through dual ER Bus communication paths.

Compact & Scalable Design

Small form factor allows for modular and space-efficient system architecture.

SIL3 Safety Certified

Compliance with IEC 61508 makes it suitable for critical applications.

Easy Integration

Seamlessly integrates with ProSafe-RS engineering tools and controller systems.

Built-in Diagnostics

Real-time fault detection and status indication for faster troubleshooting.

Low Power Operation

Energy-efficient design reduces thermal load in control cabinets.

Environment-Resistant

Tolerant to industrial conditions with wide temperature and humidity range.

Frequently Asked Questions (FAQ)

Q: What system is the ANS20 designed for?

A: It is built specifically for Yokogawa’s ProSafe-RS Safety Instrumented System.

Q: Does it support redundant communication?

A: Yes, ANS20 supports dual-path ER Bus redundancy for fault-tolerant operations.

Q: Can the unit be hot-swapped during operation?

A: No, the unit must be powered down for safe replacement or maintenance.

Q: What is the unit’s safety certification level?

A: It is certified to SIL3 per IEC 61508 standards.

Q: What diagnostics features are included?

A: LED indicators for fault, status, and communication health; internal self-checking.

Q: Is the ANS20 suitable for offshore use?

A: Yes, it meets ATEX and marine certifications suitable for offshore installations.

Q: How is the unit mounted?

A: It is DIN rail mountable for standard industrial enclosures.

Q: What is the max distance it supports via ER Bus?

A: Each ER Bus segment supports up to 100 meters (depending on cable type).

Q: Can it interface with multiple I/O modules?

A: Yes, it serves as a communication gateway for several distributed I/O modules.

Q: How is firmware upgraded?

A: Firmware updates are applied using the system’s engineering tools (e.g., SENG).

Yokogawa ANS20 Node Interface Unit

Manufacturer:Yokogawa

Product Number:ANS20

Product Type:Node Interface Unit

Origin:Japan

Dimensions:30 × 130 × 100 mm

Weight:0.36 kg

Views:87

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa ANS20 Node Interface Unit is an essential component of the ProSafe-RS safety instrumented system, functioning as a critical interface between subsystems and the main safety control units. It is specifically designed to manage redundant communication and ensure robust data transfer over the safety control network, contributing to safe, efficient, and fail-proof plant operation.

As part of Yokogawa’s modular safety platform, the ANS20 provides a reliable communication link between distributed input/output (I/O) nodes and the central controller (AFV10D CPU), enabling high-integrity, SIL-rated communication even under harsh industrial conditions. Its compact design and integration with Yokogawa’s ER Bus (Extension Redundant Bus) allow for simplified installation, scalability, and system diagnostics.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | ANS20 |

| Product Type | Node Interface Unit |

| System Platform | Yokogawa ProSafe-RS |

| Communication Bus | ER Bus (Extension Redundant Bus) |

| Redundancy | Supported (Dual path redundancy) |

| Power Supply Voltage | 24 VDC nominal (supplied via baseplate) |

| Power Consumption | Approx. 120–160 mA |

| Input/Output Channels | Acts as gateway for multiple I/O modules |

| Communication Speed | Up to 1 Mbps |

| Mounting Type | DIN Rail Mountable |

| Operating Temperature | 0°C to +55°C (32°F to 131°F) |

| Storage Temperature | -20°C to +70°C (-4°F to 158°F) |

| Humidity Tolerance | 5% to 95% RH, non-condensing |

| Ingress Protection | IP30 (when installed in cabinet) |

| Certifications | SIL3 (IEC 61508), CE, ATEX, FM, CSA |

| Firmware Upgradeable | Yes (via engineering tool) |

| Diagnostics | Built-in diagnostics and status LEDs |

| Dimensions (W × H × D) | 30 × 130 × 100 mm |

| Weight | 0.36 kg |

Product Applications

The ANS20 Node Interface Unit is primarily used in distributed safety control environments, enabling safe communication across multiple I/O nodes. Its robust design and SIL3 certification make it ideal for:

Emergency Shutdown Systems (ESD)

Allows for high-integrity safety operations across distributed plant areas.

Fire & Gas Systems (FGS)

Ensures reliable transmission of alarm and sensor signals to the central controller.

Burner Management Systems (BMS)

Facilitates safe operation and shutdown of combustion systems.

Pipeline Safety Systems

Used in oil & gas pipelines to manage safety barriers remotely.

Offshore Platforms & FPSOs

Designed for safety systems where distributed topology is critical.

Power Generation Facilities

Ensures safe and synchronized communication for turbine or boiler protection systems.

Product Advantages

Redundant Communication Support

Ensures continuous operation through dual ER Bus communication paths.

Compact & Scalable Design

Small form factor allows for modular and space-efficient system architecture.

SIL3 Safety Certified

Compliance with IEC 61508 makes it suitable for critical applications.

Easy Integration

Seamlessly integrates with ProSafe-RS engineering tools and controller systems.

Built-in Diagnostics

Real-time fault detection and status indication for faster troubleshooting.

Low Power Operation

Energy-efficient design reduces thermal load in control cabinets.

Environment-Resistant

Tolerant to industrial conditions with wide temperature and humidity range.

Frequently Asked Questions (FAQ)

Q: What system is the ANS20 designed for?

A: It is built specifically for Yokogawa’s ProSafe-RS Safety Instrumented System.

Q: Does it support redundant communication?

A: Yes, ANS20 supports dual-path ER Bus redundancy for fault-tolerant operations.

Q: Can the unit be hot-swapped during operation?

A: No, the unit must be powered down for safe replacement or maintenance.

Q: What is the unit’s safety certification level?

A: It is certified to SIL3 per IEC 61508 standards.

Q: What diagnostics features are included?

A: LED indicators for fault, status, and communication health; internal self-checking.

Q: Is the ANS20 suitable for offshore use?

A: Yes, it meets ATEX and marine certifications suitable for offshore installations.

Q: How is the unit mounted?

A: It is DIN rail mountable for standard industrial enclosures.

Q: What is the max distance it supports via ER Bus?

A: Each ER Bus segment supports up to 100 meters (depending on cable type).

Q: Can it interface with multiple I/O modules?

A: Yes, it serves as a communication gateway for several distributed I/O modules.

Q: How is firmware upgraded?

A: Firmware updates are applied using the system’s engineering tools (e.g., SENG).

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...