Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

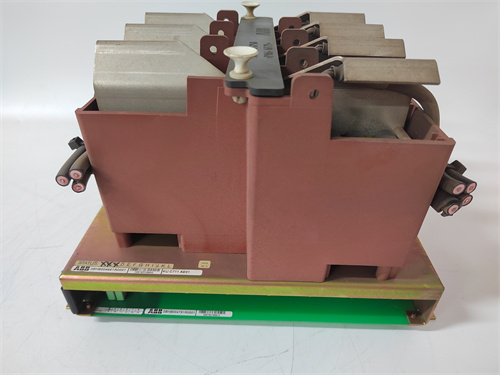

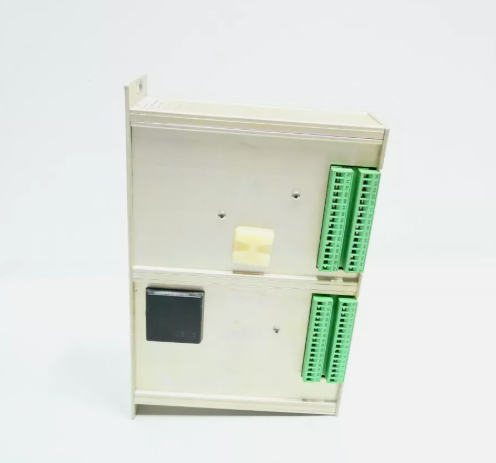

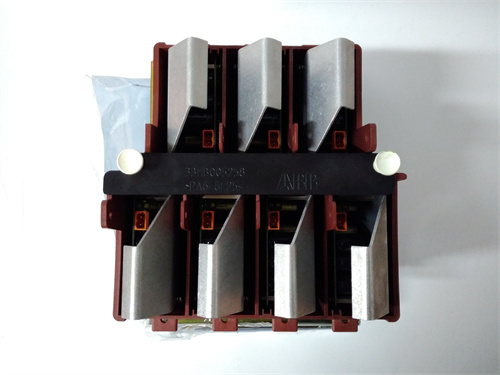

ABB CI840 3BSE022457R1 Redundant Profibus Communications Interface

Manufacture :ABB

Item No :CI840

Article number :3BSE022457R1

Series :800XA Control Systems

Origin :Sweden

Dimension :127*76*127(mm)

Weight :0.3kg

Customs Tariff Number :85389091

Type :Communications Interface

Product Description

S800 I/O is a comprehensive, distributed and modular process I/O system that communicates with parent controllers and PLCs over industry-standard field buses. The CI840 Fieldbus Communication Interface (FCI) module is a configurable communication interface that performs operations such as signal processing, gathering of various supervision information, OSP handling, Hot Configuration In Run, HART pass-through and configuration of I/O modules. CI840 is designed for redundant applications. The FCI connects to the controller by way of the PROFIBUS-DPV1 fieldbus. Module termination units to use, TU846 with redundant I/O and TU847 with non-redundant I/O.

Detailed data

24 V consumption type 190 mA

Electrical safety EN 61010-1, UL 61010-1, EN 61010-2-201, UL 61010-2-201

Hazardous locations C1 Div 2 cULus, C1 Zone 2 cULus, ATEX Zone 2

Maritime certification ABS, BV, DNV-GL, LR

Operating temperature 0 to +55 °C (+32 to +131 °F), certified temperature +5 to +55 °C

Storage temperature -40 to +70 °C (-40 to +158 °F)

Pollution degree 2, IEC 60664-1

Corrosion protection ISA-S71.04: G3

Relative humidity 5 to 95%, non-condensing

Maximum ambient temperature 55 °C (131 °F), 40 °C when installed vertically (104 °F)

Protection class IP20, EN60529, IEC 529

Complies with RoHS Directive/2011/65/EU (EN 50581:2012)

Complies with WEEE Directive/2012/19/EU

Frequently asked questions about the product are as follows:

-What is ABB CI840?

ABB CI840 is an Ethernet communication interface module for AC800M PLC systems. It provides high-speed Ethernet connectivity to enable communication between PLCs and other networked devices.

-What is the main purpose of the ABB CI840 module?

The CI840 module is mainly used to provide Ethernet communications for AC800M PLC, facilitating communication between PLCs and other devices over Ethernet networks. It integrates with remote I/O devices. Connects to supervisory systems for monitoring and control. It can also exchange data with other PLC or automation systems via Ethernet/IP or Modbus TCP. Connects PLC to industrial networks.

-How does CI840 integrate with AC800M PLC?

The CI840 plugs into the communication module slot of the AC800M PLC. Once physically installed, it can be configured through ABB Control Builder or Automation Builder software. These software tools allow network setup, communication parameters for Ethernet/IP, Modbus TCP and other protocols, I/O data mapping and integration with external devices over Ethernet.

ABB CI840 3BSE022457R1 Redundant Profibus Communications Interface

Manufacture :ABB

Item No :CI840

Article number :3BSE022457R1

Series :800XA Control Systems

Origin :Sweden

Dimension :127*76*127(mm)

Weight :0.3kg

Customs Tariff Number :85389091

Type :Communications Interface

Product Description

S800 I/O is a comprehensive, distributed and modular process I/O system that communicates with parent controllers and PLCs over industry-standard field buses. The CI840 Fieldbus Communication Interface (FCI) module is a configurable communication interface that performs operations such as signal processing, gathering of various supervision information, OSP handling, Hot Configuration In Run, HART pass-through and configuration of I/O modules. CI840 is designed for redundant applications. The FCI connects to the controller by way of the PROFIBUS-DPV1 fieldbus. Module termination units to use, TU846 with redundant I/O and TU847 with non-redundant I/O.

Detailed data

24 V consumption type 190 mA

Electrical safety EN 61010-1, UL 61010-1, EN 61010-2-201, UL 61010-2-201

Hazardous locations C1 Div 2 cULus, C1 Zone 2 cULus, ATEX Zone 2

Maritime certification ABS, BV, DNV-GL, LR

Operating temperature 0 to +55 °C (+32 to +131 °F), certified temperature +5 to +55 °C

Storage temperature -40 to +70 °C (-40 to +158 °F)

Pollution degree 2, IEC 60664-1

Corrosion protection ISA-S71.04: G3

Relative humidity 5 to 95%, non-condensing

Maximum ambient temperature 55 °C (131 °F), 40 °C when installed vertically (104 °F)

Protection class IP20, EN60529, IEC 529

Complies with RoHS Directive/2011/65/EU (EN 50581:2012)

Complies with WEEE Directive/2012/19/EU

Frequently asked questions about the product are as follows:

-What is ABB CI840?

ABB CI840 is an Ethernet communication interface module for AC800M PLC systems. It provides high-speed Ethernet connectivity to enable communication between PLCs and other networked devices.

-What is the main purpose of the ABB CI840 module?

The CI840 module is mainly used to provide Ethernet communications for AC800M PLC, facilitating communication between PLCs and other devices over Ethernet networks. It integrates with remote I/O devices. Connects to supervisory systems for monitoring and control. It can also exchange data with other PLC or automation systems via Ethernet/IP or Modbus TCP. Connects PLC to industrial networks.

-How does CI840 integrate with AC800M PLC?

The CI840 plugs into the communication module slot of the AC800M PLC. Once physically installed, it can be configured through ABB Control Builder or Automation Builder software. These software tools allow network setup, communication parameters for Ethernet/IP, Modbus TCP and other protocols, I/O data mapping and integration with external devices over Ethernet.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...