Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

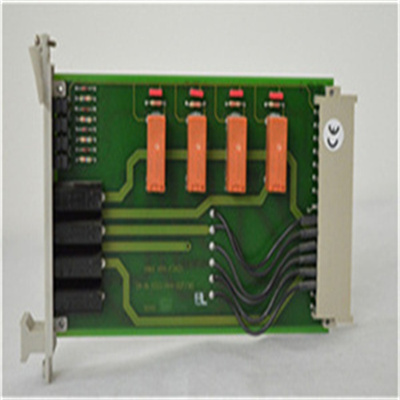

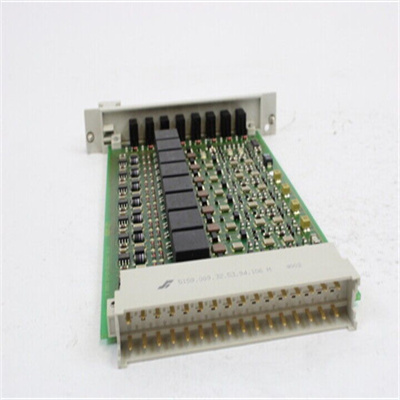

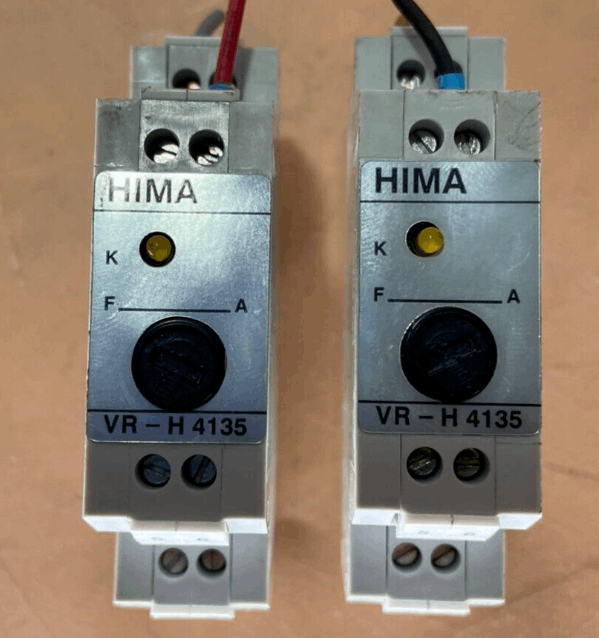

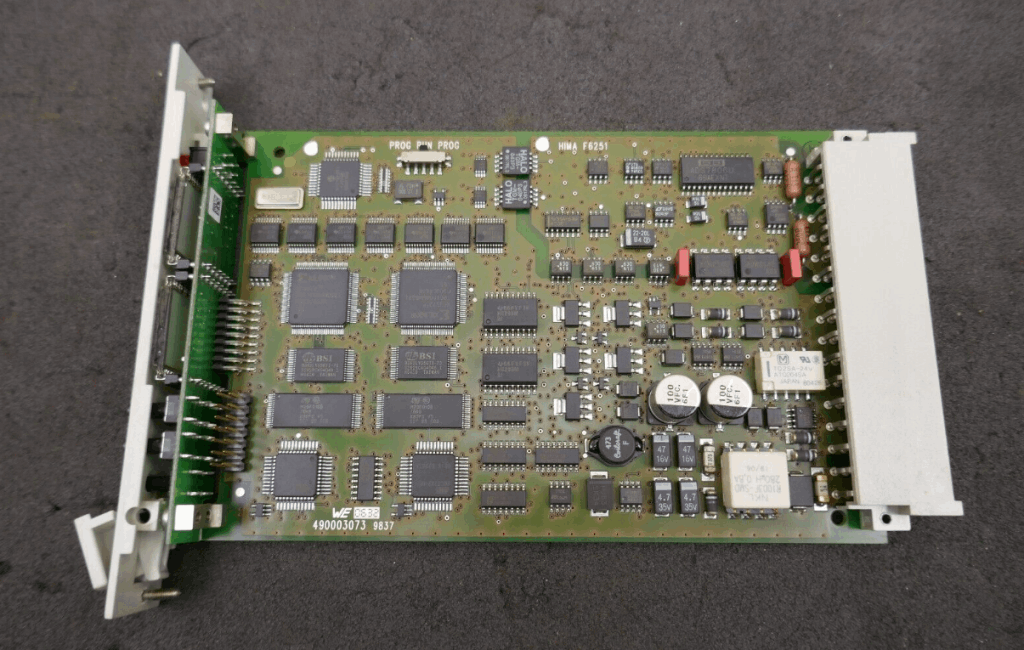

Hima F4102 PRINTED CIRCUIT BOARD

Manufacturer:HIMA

Product Number:F4102

Product Type:PRINTED CIRCUIT BOARD

Origin:Germany

Dimensions:130 x 100 x 60mm

Weight :0.6 kg

Views:118

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

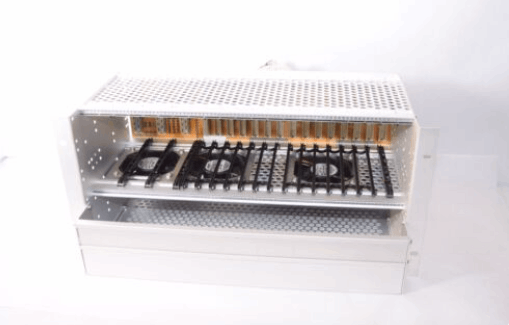

The HIMA F4102 is a high-performance and reliable safety system controller designed for demanding industrial applications. It is part of the F4xx series of safety systems, which are well-known for their robustness, flexibility, and scalability. The F4102 is equipped with advanced safety features, providing high levels of protection for critical systems. It is especially suitable for use in process automation, chemical plants, and oil and gas industries, where safety and reliability are paramount.

Product Specifications

The HIMA F4102 offers several key features that ensure optimal safety, performance, and integration with existing systems. Below is a detailed table summarizing its key specifications.

| Specification | Details |

|---|---|

| Dimensions | 130 x 100 x 60mm |

| Weight | 0.6 kg |

| Power Supply | 24 V DC ± 20% |

| Input Type | Digital, Analog |

| Output Type | Digital, Relay |

| Environmental Temp. | -20°C to +60°C |

| Protection Class | IP20 |

| Mounting | DIN rail |

| Communication | Modbus, Profibus, Ethernet |

| Safety Integrity Level (SIL) | SIL 3 (IEC 61508) |

| Certification | CE, UL, FM |

Applications

The HIMA F4102 is ideal for safety-critical applications in industries such as:

Process automation: Ensuring the safe operation of chemical, pharmaceutical, and petrochemical plants.

Power generation: Protecting equipment and systems within power plants, such as turbines, generators, and boilers.

Oil and gas: Providing safety for oil rigs, pipelines, and refineries where hazardous conditions prevail.

Transportation: Managing safety systems in railways and airports to ensure the safety of passengers and staff.

Manufacturing: Monitoring and controlling processes in industries like automotive, food, and beverages.

Product Advantages

High Safety Standards: The F4102 meets SIL 3 safety requirements, ensuring the highest level of protection for critical processes.

Flexible Integration: It supports various communication protocols (Modbus, Profibus, Ethernet), allowing easy integration into existing infrastructure.

Compact Design: The compact form factor enables installation in space-constrained environments, reducing the need for large control cabinets.

High Reliability: Built to withstand extreme conditions (temperature range from -20°C to +60°C) and offering high MTBF (Mean Time Between Failures), making it ideal for continuous operation in harsh industrial settings.

Modular and Scalable: Its modular design allows for easy system expansion, accommodating increasing demands or changes in plant processes.

Easy Configuration: Intuitive software for system configuration and programming simplifies setup and minimizes installation time.

FAQs

What is the safety integrity level (SIL) of the HIMA F4102?

-

The HIMA F4102 meets SIL 3 requirements as per IEC 61508, ensuring it provides high levels of safety for critical applications.

-

What industries can benefit from using the HIMA F4102?

-

The HIMA F4102 is ideal for industries such as oil and gas, chemical manufacturing, power generation, and transportation.

-

How is the HIMA F4102 mounted?

-

The F4102 is designed to be mounted on a DIN rail, making installation straightforward and compatible with standard industrial setups.

-

What are the communication protocols supported by the F4102?

-

The device supports Modbus, Profibus, and Ethernet, enabling flexible integration into various automation systems.

-

What is the operating temperature range of the F4102?

-

The HIMA F4102 operates within a temperature range of -20°C to +60°C, making it suitable for harsh environments.

-

Is the HIMA F4102 compatible with other HIMA safety systems?

-

Yes, the F4102 is fully compatible with other HIMA safety controllers, enabling seamless integration into a larger safety network.

-

What certifications does the HIMA F4102 have?

-

The device is certified for CE, UL, and FM, ensuring compliance with global standards for safety and performance.

-

Can the HIMA F4102 handle analog and digital inputs/outputs?

-

Yes, it supports both digital and analog inputs and outputs, making it versatile for various applications.

-

What is the power supply requirement for the F4102?

-

The device requires a 24 V DC ± 20% power supply to operate.

-

What is the weight of the HIMA F4102?

-

The unit weighs 0.6 kg, which is relatively lightweight for its size and functionality.

-

Hima F4102 PRINTED CIRCUIT BOARD

Manufacturer:HIMA

Product Number:F4102

Product Type:PRINTED CIRCUIT BOARD

Origin:Germany

Dimensions:130 x 100 x 60mm

Weight :0.6 kg

Views:118

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The HIMA F4102 is a high-performance and reliable safety system controller designed for demanding industrial applications. It is part of the F4xx series of safety systems, which are well-known for their robustness, flexibility, and scalability. The F4102 is equipped with advanced safety features, providing high levels of protection for critical systems. It is especially suitable for use in process automation, chemical plants, and oil and gas industries, where safety and reliability are paramount.

Product Specifications

The HIMA F4102 offers several key features that ensure optimal safety, performance, and integration with existing systems. Below is a detailed table summarizing its key specifications.

| Specification | Details |

|---|---|

| Dimensions | 130 x 100 x 60mm |

| Weight | 0.6 kg |

| Power Supply | 24 V DC ± 20% |

| Input Type | Digital, Analog |

| Output Type | Digital, Relay |

| Environmental Temp. | -20°C to +60°C |

| Protection Class | IP20 |

| Mounting | DIN rail |

| Communication | Modbus, Profibus, Ethernet |

| Safety Integrity Level (SIL) | SIL 3 (IEC 61508) |

| Certification | CE, UL, FM |

Applications

The HIMA F4102 is ideal for safety-critical applications in industries such as:

Process automation: Ensuring the safe operation of chemical, pharmaceutical, and petrochemical plants.

Power generation: Protecting equipment and systems within power plants, such as turbines, generators, and boilers.

Oil and gas: Providing safety for oil rigs, pipelines, and refineries where hazardous conditions prevail.

Transportation: Managing safety systems in railways and airports to ensure the safety of passengers and staff.

Manufacturing: Monitoring and controlling processes in industries like automotive, food, and beverages.

Product Advantages

High Safety Standards: The F4102 meets SIL 3 safety requirements, ensuring the highest level of protection for critical processes.

Flexible Integration: It supports various communication protocols (Modbus, Profibus, Ethernet), allowing easy integration into existing infrastructure.

Compact Design: The compact form factor enables installation in space-constrained environments, reducing the need for large control cabinets.

High Reliability: Built to withstand extreme conditions (temperature range from -20°C to +60°C) and offering high MTBF (Mean Time Between Failures), making it ideal for continuous operation in harsh industrial settings.

Modular and Scalable: Its modular design allows for easy system expansion, accommodating increasing demands or changes in plant processes.

Easy Configuration: Intuitive software for system configuration and programming simplifies setup and minimizes installation time.

FAQs

What is the safety integrity level (SIL) of the HIMA F4102?

-

The HIMA F4102 meets SIL 3 requirements as per IEC 61508, ensuring it provides high levels of safety for critical applications.

-

What industries can benefit from using the HIMA F4102?

-

The HIMA F4102 is ideal for industries such as oil and gas, chemical manufacturing, power generation, and transportation.

-

How is the HIMA F4102 mounted?

-

The F4102 is designed to be mounted on a DIN rail, making installation straightforward and compatible with standard industrial setups.

-

What are the communication protocols supported by the F4102?

-

The device supports Modbus, Profibus, and Ethernet, enabling flexible integration into various automation systems.

-

What is the operating temperature range of the F4102?

-

The HIMA F4102 operates within a temperature range of -20°C to +60°C, making it suitable for harsh environments.

-

Is the HIMA F4102 compatible with other HIMA safety systems?

-

Yes, the F4102 is fully compatible with other HIMA safety controllers, enabling seamless integration into a larger safety network.

-

What certifications does the HIMA F4102 have?

-

The device is certified for CE, UL, and FM, ensuring compliance with global standards for safety and performance.

-

Can the HIMA F4102 handle analog and digital inputs/outputs?

-

Yes, it supports both digital and analog inputs and outputs, making it versatile for various applications.

-

What is the power supply requirement for the F4102?

-

The device requires a 24 V DC ± 20% power supply to operate.

-

What is the weight of the HIMA F4102?

-

The unit weighs 0.6 kg, which is relatively lightweight for its size and functionality.

-

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...