Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

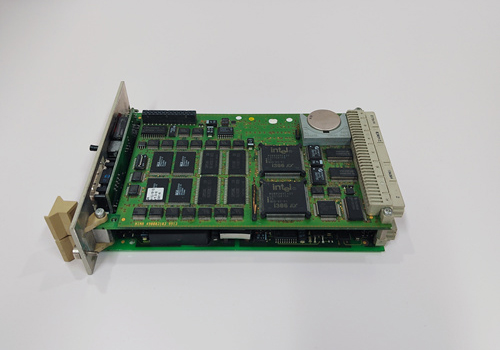

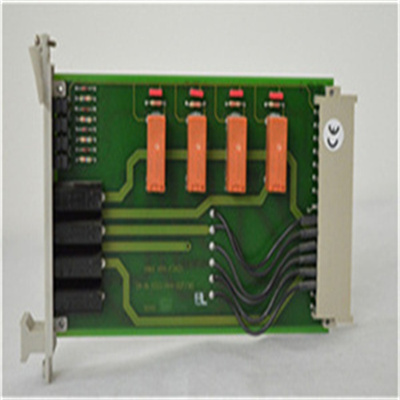

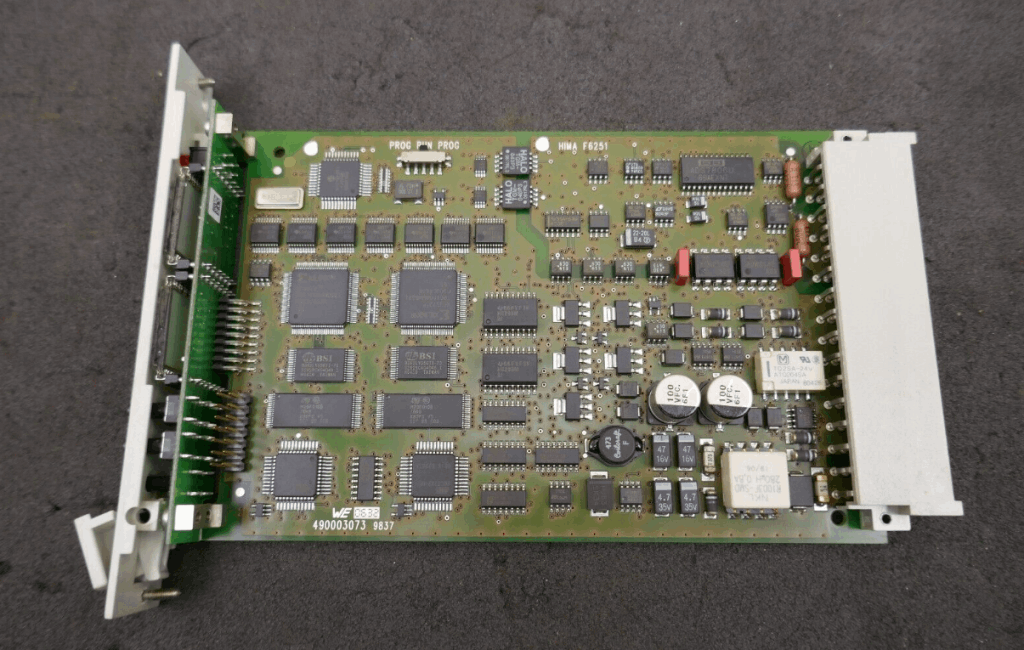

Hima F8627 Ethernet Communication Module

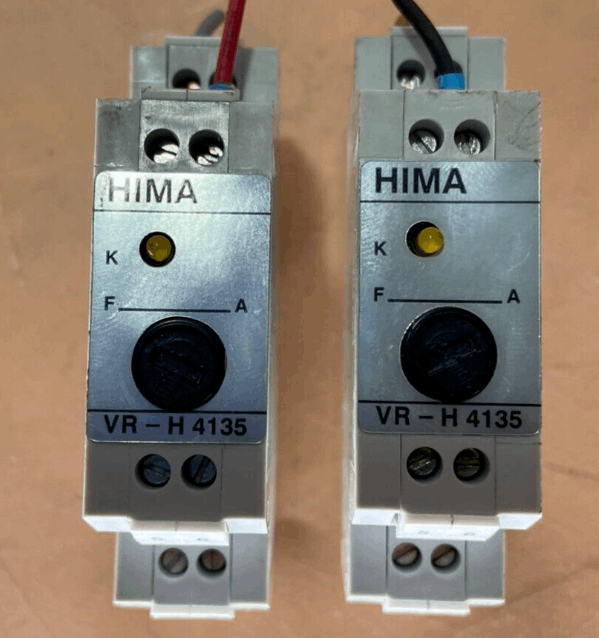

Manufacturer:HIMA

Product Number:F8627

Product Type:Ethernet Communication Module

Origin:Germany

Dimensions:160 x 100 x 30 mm

Weight:0.34 kg

Views:56

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The HIMA F8627 Ethernet Communication Module is a high-performance industrial communication module designed for integration into HIMA’s HIMax and HIQuad safety systems. Developed by HIMA Paul Hildebrandt GmbH, a global leader in safety automation solutions, the F8627 module enables seamless data exchange between safety systems and higher-level controllers, SCADA systems, engineering stations, and remote devices.

The module is designed to provide a reliable and secure Ethernet interface that supports standard communication protocols, including TCP/IP, MODBUS TCP, and HIMA-specific communication protocols. With its robust design and strict adherence to safety requirements, the F8627 is suitable for applications in critical infrastructure environments such as oil & gas, chemical, power generation, and transportation.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | HIMA F8627 |

| Function | Ethernet Communication Module |

| Supported Protocols | TCP/IP, MODBUS TCP, HIMA Remote Services, SNTP, SNMP |

| Ports | 2 × RJ45 Ethernet Ports |

| Transmission Rate | 10/100 Mbps (Auto-negotiation) |

| Redundancy Support | Yes (hot-standby configuration supported) |

| Configuration Tool | HIMA ELOP II / SILworX |

| Diagnostics | Integrated LED indicators for link/activity/status |

| Power Supply Voltage | 24 V DC (supplied via backplane) |

| Power Consumption | Approx. 3.5 W |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5% to 95% (non-condensing) |

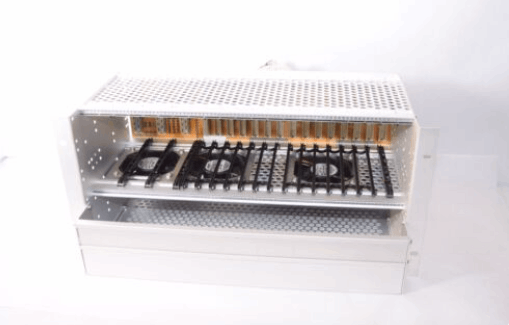

| Installation | Plug-in module (for HIMax or HIQuad racks) |

| Certifications | SIL 3 (IEC 61508), ATEX, CE, CSA, UL |

| Dimensions (W × H × D) | 160 x 100 x 30 mm |

| Weight | 0.34 kg |

Applications

The HIMA F8627 module is extensively used in mission-critical applications where secure and deterministic Ethernet communication is required between safety controllers and enterprise-level systems. Typical applications include:

-

Oil and Gas Platforms: For real-time monitoring and control of offshore safety systems.

-

Petrochemical Plants: Interfacing process safety systems with plant DCS and HMI.

-

Power Generation: Communication bridge between turbine protection systems and SCADA.

-

Railway Systems: Used in signaling, interlocking, and control networks.

-

Chemical Processing Units: Reliable communication in hazardous and safety-rated zones.

-

Remote Facility Management: Enabling remote diagnostics and firmware updates.

Product Advantages

-

High Reliability: Designed for use in SIL 3-rated systems, ensuring dependable communication.

-

Industrial Hardened Design: Withstands harsh environments, including vibration, temperature fluctuation, and electromagnetic interference.

-

Protocol Versatility: Supports multiple standard industrial protocols including MODBUS TCP, enabling integration into heterogeneous networks.

-

Redundancy Support: Offers hot-standby communication for high-availability applications.

-

Simple Integration: Seamlessly integrates with HIMA SILworX and ELOP II tools for easy configuration and maintenance.

-

Secure Data Transfer: Built-in cybersecurity features minimize vulnerabilities in networked environments.

-

LED Diagnostics: Provides clear visual indicators for fault detection and troubleshooting.

-

Long Product Life Cycle: Backed by HIMA’s commitment to long-term support for industrial automation hardware.

Frequently Asked Questions (FAQ)

-

Q: What is the primary function of the HIMA F8627 module?

A: It acts as an Ethernet communication interface for HIMA safety controllers, enabling data exchange with SCADA, DCS, and remote stations.

-

Q: Which software tools are used to configure the F8627?

A: The module is configured using HIMA ELOP II and SILworX platforms.

-

Q: Is the F8627 compatible with standard Ethernet switches?

A: Yes, it supports standard 10/100 Mbps Ethernet switches.

-

Q: Does it support redundancy?

A: Yes, it allows hot-standby redundancy for critical communication applications.

-

Q: Can the F8627 be used in SIL 3 applications?

A: Absolutely, it is certified according to IEC 61508 for SIL 3 safety integrity level.

-

Q: What types of network protocols does it support?

A: It supports TCP/IP, MODBUS TCP, SNMP, SNTP, and HIMA’s proprietary protocols.

-

Q: What kind of diagnostics does it offer?

A: It has onboard LEDs for link, activity, and module status indicators.

-

Q: Is the module suitable for use in hazardous environments?

A: Yes, it is ATEX certified for use in explosive atmospheres.

-

Q: What is the recommended operating temperature range?

A: The module operates reliably between 0°C to +60°C.

-

Q: How is the module installed in the system?

A: It is installed as a plug-in module into HIMA HIMax or HIQuad racks.

Hima F8627 Ethernet Communication Module

Manufacturer:HIMA

Product Number:F8627

Product Type:Ethernet Communication Module

Origin:Germany

Dimensions:160 x 100 x 30 mm

Weight:0.34 kg

Views:56

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The HIMA F8627 Ethernet Communication Module is a high-performance industrial communication module designed for integration into HIMA’s HIMax and HIQuad safety systems. Developed by HIMA Paul Hildebrandt GmbH, a global leader in safety automation solutions, the F8627 module enables seamless data exchange between safety systems and higher-level controllers, SCADA systems, engineering stations, and remote devices.

The module is designed to provide a reliable and secure Ethernet interface that supports standard communication protocols, including TCP/IP, MODBUS TCP, and HIMA-specific communication protocols. With its robust design and strict adherence to safety requirements, the F8627 is suitable for applications in critical infrastructure environments such as oil & gas, chemical, power generation, and transportation.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | HIMA F8627 |

| Function | Ethernet Communication Module |

| Supported Protocols | TCP/IP, MODBUS TCP, HIMA Remote Services, SNTP, SNMP |

| Ports | 2 × RJ45 Ethernet Ports |

| Transmission Rate | 10/100 Mbps (Auto-negotiation) |

| Redundancy Support | Yes (hot-standby configuration supported) |

| Configuration Tool | HIMA ELOP II / SILworX |

| Diagnostics | Integrated LED indicators for link/activity/status |

| Power Supply Voltage | 24 V DC (supplied via backplane) |

| Power Consumption | Approx. 3.5 W |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5% to 95% (non-condensing) |

| Installation | Plug-in module (for HIMax or HIQuad racks) |

| Certifications | SIL 3 (IEC 61508), ATEX, CE, CSA, UL |

| Dimensions (W × H × D) | 160 x 100 x 30 mm |

| Weight | 0.34 kg |

Applications

The HIMA F8627 module is extensively used in mission-critical applications where secure and deterministic Ethernet communication is required between safety controllers and enterprise-level systems. Typical applications include:

-

Oil and Gas Platforms: For real-time monitoring and control of offshore safety systems.

-

Petrochemical Plants: Interfacing process safety systems with plant DCS and HMI.

-

Power Generation: Communication bridge between turbine protection systems and SCADA.

-

Railway Systems: Used in signaling, interlocking, and control networks.

-

Chemical Processing Units: Reliable communication in hazardous and safety-rated zones.

-

Remote Facility Management: Enabling remote diagnostics and firmware updates.

Product Advantages

-

High Reliability: Designed for use in SIL 3-rated systems, ensuring dependable communication.

-

Industrial Hardened Design: Withstands harsh environments, including vibration, temperature fluctuation, and electromagnetic interference.

-

Protocol Versatility: Supports multiple standard industrial protocols including MODBUS TCP, enabling integration into heterogeneous networks.

-

Redundancy Support: Offers hot-standby communication for high-availability applications.

-

Simple Integration: Seamlessly integrates with HIMA SILworX and ELOP II tools for easy configuration and maintenance.

-

Secure Data Transfer: Built-in cybersecurity features minimize vulnerabilities in networked environments.

-

LED Diagnostics: Provides clear visual indicators for fault detection and troubleshooting.

-

Long Product Life Cycle: Backed by HIMA’s commitment to long-term support for industrial automation hardware.

Frequently Asked Questions (FAQ)

-

Q: What is the primary function of the HIMA F8627 module?

A: It acts as an Ethernet communication interface for HIMA safety controllers, enabling data exchange with SCADA, DCS, and remote stations.

-

Q: Which software tools are used to configure the F8627?

A: The module is configured using HIMA ELOP II and SILworX platforms.

-

Q: Is the F8627 compatible with standard Ethernet switches?

A: Yes, it supports standard 10/100 Mbps Ethernet switches.

-

Q: Does it support redundancy?

A: Yes, it allows hot-standby redundancy for critical communication applications.

-

Q: Can the F8627 be used in SIL 3 applications?

A: Absolutely, it is certified according to IEC 61508 for SIL 3 safety integrity level.

-

Q: What types of network protocols does it support?

A: It supports TCP/IP, MODBUS TCP, SNMP, SNTP, and HIMA’s proprietary protocols.

-

Q: What kind of diagnostics does it offer?

A: It has onboard LEDs for link, activity, and module status indicators.

-

Q: Is the module suitable for use in hazardous environments?

A: Yes, it is ATEX certified for use in explosive atmospheres.

-

Q: What is the recommended operating temperature range?

A: The module operates reliably between 0°C to +60°C.

-

Q: How is the module installed in the system?

A: It is installed as a plug-in module into HIMA HIMax or HIQuad racks.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...