Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

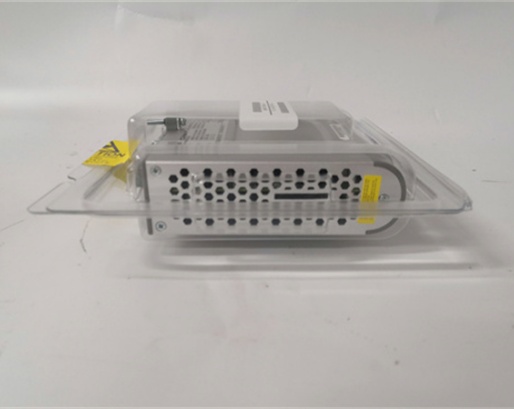

Honeywell CC-PFB402 Fieldbus Interface Modules

Manufacturer:Honeywell

Product Number:CC-PFB402

Product Type:Fieldbus Interface Modules

Origin:USA

Dimensions:63.5 x 124.46 x 307.34 mm

Weight:0.408kg

Views:42

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

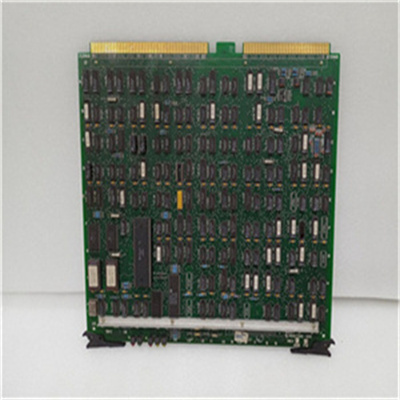

The Honeywell CC-PFB402 is a high-performance Fieldbus Interface Module designed to integrate Foundation Fieldbus devices with Honeywell’s Experion Process Knowledge System (PKS). As part of the ControlEdge and C300 controller families, it enables seamless communication between intelligent field devices and control systems. With its robust architecture, fault tolerance, and diagnostic capabilities, the CC-PFB402 supports complex fieldbus networks, enhancing plant reliability and efficiency.

Key Features

-

Supports up to 2 Foundation Fieldbus H1 segments

-

Full integration with Honeywell Experion PKS

-

Redundant configuration capability

-

Advanced diagnostics and status monitoring

-

DIN rail mountable modular design

-

Hot-swappable for minimal downtime

-

Supports device configuration and control via Experion

-

Automatic device recognition and tag import

Technical Specifications

| Item | Specification |

|---|---|

| Product Type | Fieldbus Interface Module |

| Model Number | CC-PFB402 |

| Manufacturer | Honeywell |

| Communication Protocol | Foundation Fieldbus H1 |

| Number of H1 Segments | 2 per module |

| Controller Compatibility | ControlEdge, C300, Experion LX/PKS |

| Redundancy | Supported (when used in pairs) |

| Mounting Method | DIN rail |

| Power Supply | 24 VDC nominal |

| Hot Swappable | Yes |

| Device Capacity | Up to 16 field devices per segment (typical) |

| Field Device Integration | Automatic tag recognition and database import |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -20°C to +70°C |

| Relative Humidity | 5% to 95% non-condensing |

| Dimensions | 63.5 x 124.46 x 307.34 mm |

| Weight | 0.408 kg |

| Certifications | CE, CSA, UL, ATEX, IECEx, RoHS |

Industry Applications

-

Oil & Gas Process Automation

-

Chemical and Petrochemical Manufacturing

-

Power Generation Facilities

-

Water and Wastewater Treatment Plants

-

Pharmaceutical Production Systems

-

Food and Beverage Automation

-

Pulp and Paper Processing

-

Industrial Batch Control Systems

Product Advantages

-

Full System Integration: Seamlessly connects Foundation Fieldbus devices with Experion control systems

-

Redundant Operation: High availability via redundant configuration

-

Flexible Deployment: Supports up to two H1 segments per module

-

Efficient Engineering: Device templates and auto-tag import simplify setup

-

Scalable Architecture: Easily expands with growing process demands

-

Reliable Diagnostics: Real-time status and health monitoring of fieldbus networks

-

Minimized Downtime: Hot-swappable for non-disruptive maintenance

Frequently Asked Questions (FAQ)

1. What is the main function of the CC-PFB402 module?

It interfaces Foundation Fieldbus H1 devices with Honeywell’s Experion control systems.

2. How many Fieldbus segments does it support?

It supports 2 H1 segments per module.

3. Can it be used in a redundant configuration?

Yes, redundancy is fully supported when paired with another CC-PFB402.

4. Is it compatible with Honeywell C300 controllers?

Yes, it integrates seamlessly with both C300 and ControlEdge controllers.

5. Can the module be hot-swapped?

Yes, it supports hot-swapping for efficient maintenance.

6. How many devices can be connected to each segment?

Typically up to 16 devices per segment, depending on power and bandwidth.

7. Does it support automatic tag import?

Yes, it supports automatic tag recognition and import into the control system.

8. What diagnostics are available?

It provides real-time diagnostics, including device status, communication errors, and power issues.

9. What is the operating temperature range?

0°C to +60°C under standard conditions.

10. Is it suitable for hazardous environments?

Yes, it meets ATEX and IECEx certifications for use in hazardous areas.

Honeywell CC-PFB402 Fieldbus Interface Modules

Manufacturer:Honeywell

Product Number:CC-PFB402

Product Type:Fieldbus Interface Modules

Origin:USA

Dimensions:63.5 x 124.46 x 307.34 mm

Weight:0.408kg

Views:42

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell CC-PFB402 is a high-performance Fieldbus Interface Module designed to integrate Foundation Fieldbus devices with Honeywell’s Experion Process Knowledge System (PKS). As part of the ControlEdge and C300 controller families, it enables seamless communication between intelligent field devices and control systems. With its robust architecture, fault tolerance, and diagnostic capabilities, the CC-PFB402 supports complex fieldbus networks, enhancing plant reliability and efficiency.

Key Features

-

Supports up to 2 Foundation Fieldbus H1 segments

-

Full integration with Honeywell Experion PKS

-

Redundant configuration capability

-

Advanced diagnostics and status monitoring

-

DIN rail mountable modular design

-

Hot-swappable for minimal downtime

-

Supports device configuration and control via Experion

-

Automatic device recognition and tag import

Technical Specifications

| Item | Specification |

|---|---|

| Product Type | Fieldbus Interface Module |

| Model Number | CC-PFB402 |

| Manufacturer | Honeywell |

| Communication Protocol | Foundation Fieldbus H1 |

| Number of H1 Segments | 2 per module |

| Controller Compatibility | ControlEdge, C300, Experion LX/PKS |

| Redundancy | Supported (when used in pairs) |

| Mounting Method | DIN rail |

| Power Supply | 24 VDC nominal |

| Hot Swappable | Yes |

| Device Capacity | Up to 16 field devices per segment (typical) |

| Field Device Integration | Automatic tag recognition and database import |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -20°C to +70°C |

| Relative Humidity | 5% to 95% non-condensing |

| Dimensions | 63.5 x 124.46 x 307.34 mm |

| Weight | 0.408 kg |

| Certifications | CE, CSA, UL, ATEX, IECEx, RoHS |

Industry Applications

-

Oil & Gas Process Automation

-

Chemical and Petrochemical Manufacturing

-

Power Generation Facilities

-

Water and Wastewater Treatment Plants

-

Pharmaceutical Production Systems

-

Food and Beverage Automation

-

Pulp and Paper Processing

-

Industrial Batch Control Systems

Product Advantages

-

Full System Integration: Seamlessly connects Foundation Fieldbus devices with Experion control systems

-

Redundant Operation: High availability via redundant configuration

-

Flexible Deployment: Supports up to two H1 segments per module

-

Efficient Engineering: Device templates and auto-tag import simplify setup

-

Scalable Architecture: Easily expands with growing process demands

-

Reliable Diagnostics: Real-time status and health monitoring of fieldbus networks

-

Minimized Downtime: Hot-swappable for non-disruptive maintenance

Frequently Asked Questions (FAQ)

1. What is the main function of the CC-PFB402 module?

It interfaces Foundation Fieldbus H1 devices with Honeywell’s Experion control systems.

2. How many Fieldbus segments does it support?

It supports 2 H1 segments per module.

3. Can it be used in a redundant configuration?

Yes, redundancy is fully supported when paired with another CC-PFB402.

4. Is it compatible with Honeywell C300 controllers?

Yes, it integrates seamlessly with both C300 and ControlEdge controllers.

5. Can the module be hot-swapped?

Yes, it supports hot-swapping for efficient maintenance.

6. How many devices can be connected to each segment?

Typically up to 16 devices per segment, depending on power and bandwidth.

7. Does it support automatic tag import?

Yes, it supports automatic tag recognition and import into the control system.

8. What diagnostics are available?

It provides real-time diagnostics, including device status, communication errors, and power issues.

9. What is the operating temperature range?

0°C to +60°C under standard conditions.

10. Is it suitable for hazardous environments?

Yes, it meets ATEX and IECEx certifications for use in hazardous areas.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...