Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

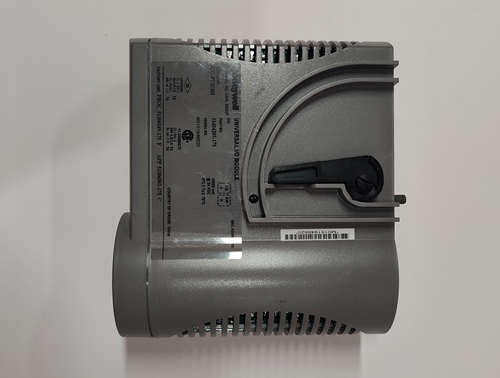

Honeywell RM7800L1038 Burner Control

Manufacturer:Honeywell

Product Number:RM7800L1038

Product Type:Burner Control

Origin:USA

Dimensions:127 x 127 x 133 mm

Weight:0.7 kg

Views:27

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell RM7800L1038 is a microprocessor-based integrated burner control designed for automatic operation of gas, oil, or dual-fuel single burner systems. It provides reliable burner sequencing, flame supervision, diagnostics, and system status indication, ensuring safety and operational efficiency in industrial combustion applications.

Technical Specifications

| Parameter | Value |

|---|---|

| Model | RM7800L1038 |

| Power Supply | 120 Vac, 50/60 Hz |

| Power Consumption | Max 10 W |

| Operating Temperature | -40°C to +60°C |

| Storage Temperature | -40°C to +66°C |

| Humidity | 85% RH non-condensing |

| Dimensions | 127 x 127 x 133 mm |

| Weight | 0.7 kg |

| Mounting | Panel or burner-mounted |

| Communication Interface | Modbus (optional) |

| Flame Failure Response Time | 0.8–3.0 seconds (by amplifier) |

| Safety Integrity Level | SIL 3 capable |

Applications

-

Industrial boilers

-

Process heaters

-

Kilns and furnaces

-

Single burner control systems in oil, gas, or combination fuel installations

-

Facilities requiring advanced diagnostics and safety interlocks

Advantages

-

Integrated safety and flame supervision

-

SIL 3 capable for high safety standards

-

Adjustable post-purge and valve proving functions

-

Non-volatile memory to store operational history and fault data

-

Wide operating temperature range for harsh environments

-

Communication-ready with optional Modbus module

-

Easy maintenance with plug-in amplifiers and purge cards

FAQ

Q1: What type of burners does the RM7800L1038 support?

A1: It supports single burners using gas, oil, or combination fuels.

Q2: What is the power supply requirement?

A2: The control operates at 120 Vac, 50/60 Hz.

Q3: Is the RM7800L1038 suitable for outdoor installation?

A3: It is recommended to install it in protected environments due to its electronics, even though it handles a wide temperature range.

Q4: Does it store fault history?

A4: Yes, it retains the six most recent fault events in non-volatile memory.

Q5: How is flame failure detected?

A5: Using a plug-in flame amplifier and detector system, with response times between 0.8–3.0 seconds.

Q6: Can I adjust the post-purge time?

A6: Yes, the post-purge time can be adjusted up to 60 minutes.

Q7: Is SIL 3 certification included?

A7: It is SIL 3 capable when installed in an appropriate safety instrumented system.

Q8: How is communication with external systems achieved?

A8: Optional Modbus or Data ControlBus modules can be used for communication.

Q9: Can the unit be remotely reset?

A9: Yes, a remote reset module is available as an option.

Q10: What kind of diagnostics does it provide?

A10: It offers detailed operational data, fault codes, flame signal strength, and sequence status.

Honeywell RM7800L1038 Burner Control

Manufacturer:Honeywell

Product Number:RM7800L1038

Product Type:Burner Control

Origin:USA

Dimensions:127 x 127 x 133 mm

Weight:0.7 kg

Views:27

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell RM7800L1038 is a microprocessor-based integrated burner control designed for automatic operation of gas, oil, or dual-fuel single burner systems. It provides reliable burner sequencing, flame supervision, diagnostics, and system status indication, ensuring safety and operational efficiency in industrial combustion applications.

Technical Specifications

| Parameter | Value |

|---|---|

| Model | RM7800L1038 |

| Power Supply | 120 Vac, 50/60 Hz |

| Power Consumption | Max 10 W |

| Operating Temperature | -40°C to +60°C |

| Storage Temperature | -40°C to +66°C |

| Humidity | 85% RH non-condensing |

| Dimensions | 127 x 127 x 133 mm |

| Weight | 0.7 kg |

| Mounting | Panel or burner-mounted |

| Communication Interface | Modbus (optional) |

| Flame Failure Response Time | 0.8–3.0 seconds (by amplifier) |

| Safety Integrity Level | SIL 3 capable |

Applications

-

Industrial boilers

-

Process heaters

-

Kilns and furnaces

-

Single burner control systems in oil, gas, or combination fuel installations

-

Facilities requiring advanced diagnostics and safety interlocks

Advantages

-

Integrated safety and flame supervision

-

SIL 3 capable for high safety standards

-

Adjustable post-purge and valve proving functions

-

Non-volatile memory to store operational history and fault data

-

Wide operating temperature range for harsh environments

-

Communication-ready with optional Modbus module

-

Easy maintenance with plug-in amplifiers and purge cards

FAQ

Q1: What type of burners does the RM7800L1038 support?

A1: It supports single burners using gas, oil, or combination fuels.

Q2: What is the power supply requirement?

A2: The control operates at 120 Vac, 50/60 Hz.

Q3: Is the RM7800L1038 suitable for outdoor installation?

A3: It is recommended to install it in protected environments due to its electronics, even though it handles a wide temperature range.

Q4: Does it store fault history?

A4: Yes, it retains the six most recent fault events in non-volatile memory.

Q5: How is flame failure detected?

A5: Using a plug-in flame amplifier and detector system, with response times between 0.8–3.0 seconds.

Q6: Can I adjust the post-purge time?

A6: Yes, the post-purge time can be adjusted up to 60 minutes.

Q7: Is SIL 3 certification included?

A7: It is SIL 3 capable when installed in an appropriate safety instrumented system.

Q8: How is communication with external systems achieved?

A8: Optional Modbus or Data ControlBus modules can be used for communication.

Q9: Can the unit be remotely reset?

A9: Yes, a remote reset module is available as an option.

Q10: What kind of diagnostics does it provide?

A10: It offers detailed operational data, fault codes, flame signal strength, and sequence status.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...