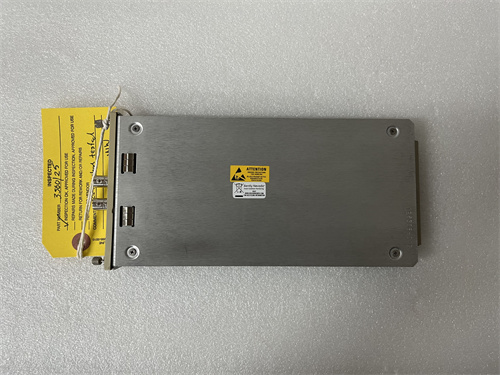

BENTLY 3500/25 149369-01 Product Overview

BENTLY 3500/25 149369-01 is an enhanced keyphaser module produced by Bently Nevada.The following is a detailed introduction to the product.

Product Overview

Model:3500/25 149369-01

Manufacturer:Bently Nevada

Type:Enhanced Keyphaser Module

Series:Bently Nevada 3500 Series

Functional Features

Signal Conversion:Receives input signals from proximity probes or magnetic pickups and converts them into digital keyphaser signals.

Keyphase Mark Alignment:Digital keyphaser signals are used to indicate when a specific mark on a rotating shaft is aligned with the keyphaser sensor.

Multi-channel Input:In normal configuration,the system can accept up to four keyphaser signals and up to eight in paired configuration.

High-precision Monitoring:Provides accurate real-time data to ensure safe and efficient operation of critical machinery.

Enhanced design:with extended signal processing capabilities and retains backward compatibility with existing key phaser modules.

Asset management data reporting:supports field-upgradeable firmware and provides asset management data reporting.

Technical specifications

Voltage:-24 Vdc is usually used as the key phase sensor power supply,with a maximum of 40 mA per channel.At the same time,the module supports a voltage range of 24VDC(18 to 36VDC).

Power consumption:3.2 watts typical and 3.2W maximum.

Dimensions:119.9 mm high,24.4 mm wide,and 256.5 mm deep(another statement is 1U high,19 inches wide,and 2.5 inches deep).

Weight:0.34 kg(another statement is about 3.5 kg).

Operating temperature:-30°C to+65°C(another statement is-40°C to 85°C),depending on the use of the internal safety barrier I/O module or the key phaser I/O module.

Input signal range:+0.8 V to-21.0 V(non-isolated I/O module)or+5V to-11V(isolated I/O module).

Input impedance:21.8 kΩminimum.

Input range:1 to 1200000 cpm(0.017 to 20 kHz).

Output range:1 to 99999 cpm(0.017 to 1667 Hz).

Output impedance:Maximum buffered output impedance 504Ω.

Response time:<1ms.

Number of channels:Dual-channel module,can monitor two different signal sources at the same time.

Application scenarios

Industrial monitoring:used to measure machine speed and monitor machine axial vibration to improve machine reliability and efficiency.

Mechanical protection:protect machines from damage by monitoring potential problems such as bearing failure.

Application areas:widely used in industrial fields such as oil and gas,power,petrochemical,papermaking,steel,etc.

Buy-Globally

Contact Us for Inquiries & Needs

If you have any questions or needs, please feel free to leave a message. Our customer service is online 24 hours a day, and we look forward to serving you.

Leave a Comment

- All comments(0)

- There are no comments yet. Come and post a comment!

Loading comments...

Loading comments...