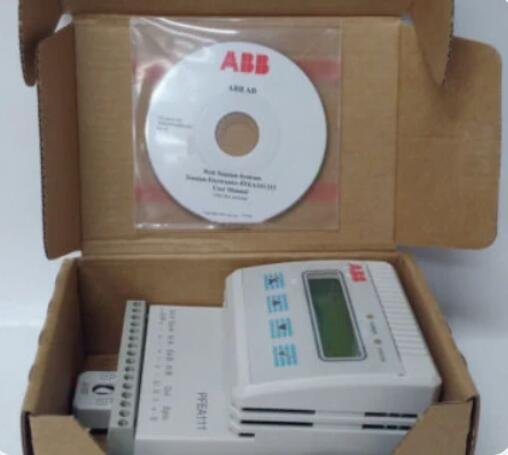

ABB PFEA111-20 Product Introduction

ABB tension controller PFEA111-20 is designed to control and adjust tension to ensure that materials or products maintain stable tension during applications such as winding,stretching and conveying.

Main features

High-precision control:The use of advanced sensors and control algorithms can achieve high-precision tension control to ensure that the tension during the production process remains stable.

Multiple input/output channels:It has multiple input/output channels for receiving and sending tension-related sensor signals and control signals,which is convenient for connection and communication with other devices.

Real-time monitoring and adjustment:It can monitor tension in real time and make real-time adjustments and controls based on feedback signals to maintain a stable tension level.

Programmability:Users can customize and configure the controller according to specific needs to adapt to different application scenarios and tension control requirements.

Multiple communication interfaces:It supports multiple communication interfaces,such as CAN,Profibus,etc.,which can be easily integrated into the automation system to achieve real-time data exchange and remote monitoring.

Safety protection measures:With overload protection,overheating protection and other safety protection measures,it ensures that the controlled equipment will not be damaged while working stably for a long time.

Application fields

ABB tension controller PFEA111-20 is widely used in the production and processing of materials such as paper,film,metal foil,fiber,wire and cable.Specific application scenarios include but are not limited to

In the winding and packaging process of paper,film,plastic and other materials,the tension controller ensures the uniformity of material tension to prevent breakage and wrinkling.

In the weaving and knitting process,the tension controller helps maintain the tension stability of the wire to ensure product quality.

In the paper conveying process,the tension controller can reduce the stretching and shrinkage of the paper to ensure printing quality.

On the papermaking machine,the tension controller controls the tension of the paper,affecting the flatness and strength of the paper.

In the extrusion and molding process,the tension controller ensures the uniform stretching of the material and improves the consistency of the finished product.

In the rolling and processing of metal strips,the tension controller controls the tension to prevent breakage and uneven thickness.

Debugging steps

For the debugging of ABB tension controller PFEA111-20,the following steps are usually included

Ensure that the tension controller is installed and wired correctly before turning on the power supply.

Check and determine whether the tension detector signal is normal.

Program the relevant parameters of the tension controller.

Calibrate the zero point and full scale of the tension signal,and confirm that the tension display is normal.

Check the system through manual adjustment and operation to confirm that the tension display is normal and the actuator operates normally.

Switch to automatic control mode,adjust the PI parameters according to the operating conditions,and ensure the smooth operation of the tension system.

ABB PFEA111-20

The New ABB Tension Electronics PFEA111-20 3BSE050090R20 is a cutting-edge device, featuring advanced technology and numerous benefits for various applications. High-Performance Device: ABB PFEA111-20 guarantees reliable and preci

Buy-Globally

Contact Us for Inquiries & Needs

If you have any questions or needs, please feel free to leave a message. Our customer service is online 24 hours a day, and we look forward to serving you.

Leave a Comment

- All comments(0)

- There are no comments yet. Come and post a comment!

Loading comments...

Loading comments...