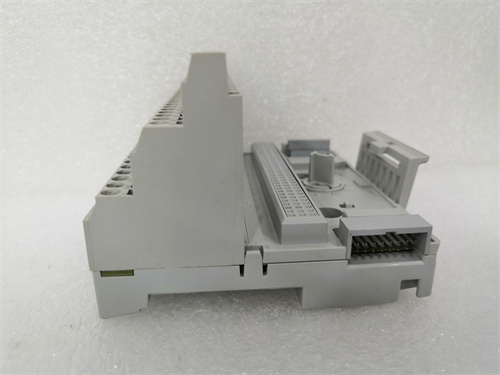

Allen-Bradley 1794-TB32 Product Overview

Allen-Bradley 1794-TB32 is a PLC(Programmable Logic Controller)module produced by Rockwell Automation,specifically a terminal base unit of the Flex I/O series.The following is a detailed introduction to the product.

Basic attributes

Brand:Allen-Bradley,a subsidiary of Rockwell Automation.

Model:1794-TB32.

Origin:United States.

Technical specifications

I/O connection capacity:32 I/O terminals,with 8 common terminals and 8 voltage terminals.

Working voltage:The working voltage is usually 24V DC/AC,but there are also materials that mention that it can support a power supply voltage range of 31.2V DC/AC,50/60Hz,and 10A.

Isolation voltage:50V continuous(some materials mention 30V continuous,which may be a difference in different versions or application scenarios).

Current capacity:FLEXBUS rated at 640mA,DC 5V;I/O terminal rated at 2A;V/COM terminal rated at 31.2V DC/AC at 50 to 60Hz.

Dimensions:Approximately 94×94×69 mm(3.7×3.7×2.7 inches).

Operating temperature range:-20 to 70 degrees Celsius(-4 to 58 degrees Fahrenheit),non-condensing humidity of 5%to 95%.

Storage temperature range:-40 to 85 degrees Celsius(-40 to 185 degrees Fahrenheit).

Vibration and shock level:Performance can be maintained within standard specifications under 5G operating vibration and 30G shock level.

Features

Terminal base unit:A terminal base unit designed specifically for 32-point modules that provides connection points for input/output wiring.

Flexibility:Can be used in a variety of industrial control applications such as CNC machinery,metallurgy,oil and gas,etc.

Reliability:The use of designs such as optocoupler circuits improves reliability.

Certification:C-UL-us and CSA certified to ensure that the product meets relevant safety standards.

Application scenarios

The Allen-Bradley 1794-TB32 module is widely used in various industrial automation systems,such as CNC machinery,metallurgy,oil and gas,paper printing,textile printing and dyeing,machinery,electronic manufacturing,automobile manufacturing and other industries.As part of the PLC system,it is responsible for receiving and processing signals from input devices and controlling the actions of output devices according to preset logical relationships.

Allen-Bradley 1794-TB32

The Allen Bradley 1794-TB32 Original Packaging Module is a versatile module designed for industrial applications. This module offers advanced features and reliable performance for efficient I/O connectivity. Features: The 1794-TB32 module c

Buy-Globally

Contact Us for Inquiries & Needs

If you have any questions or needs, please feel free to leave a message. Our customer service is online 24 hours a day, and we look forward to serving you.

Leave a Comment

- All comments(0)

- There are no comments yet. Come and post a comment!

Loading comments...

Loading comments...