Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

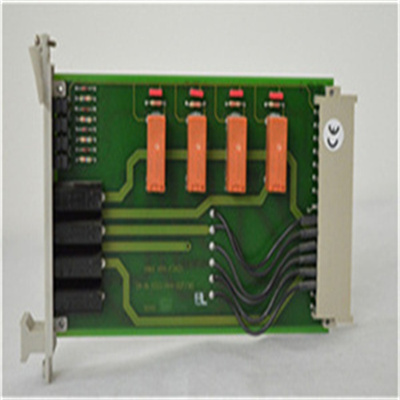

Hima F35 011 Safety Related Controller

Manufacturer:HIMA

Product Number:F35 011

Product Type:Safety Related Controller

Origin:Germany

Dimensions:257 x 114 x 97 mm

Weight:1.2 kg

Views:47

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

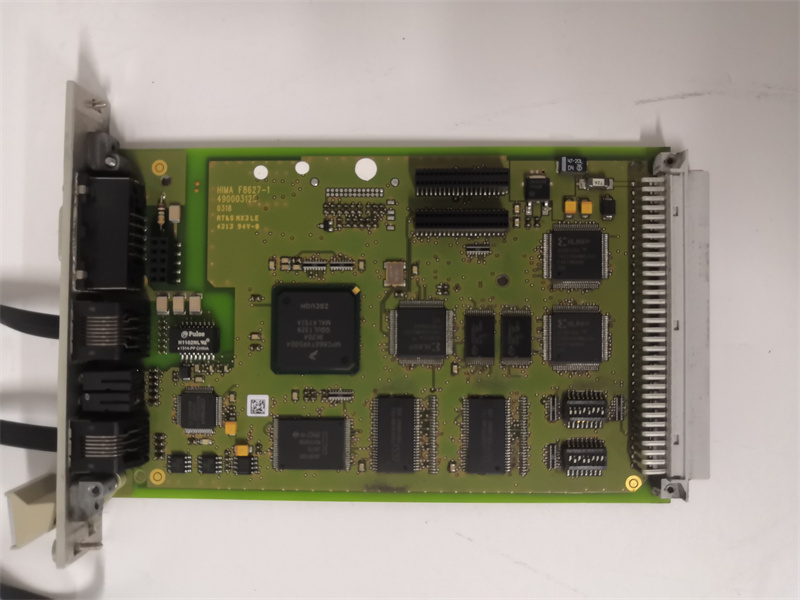

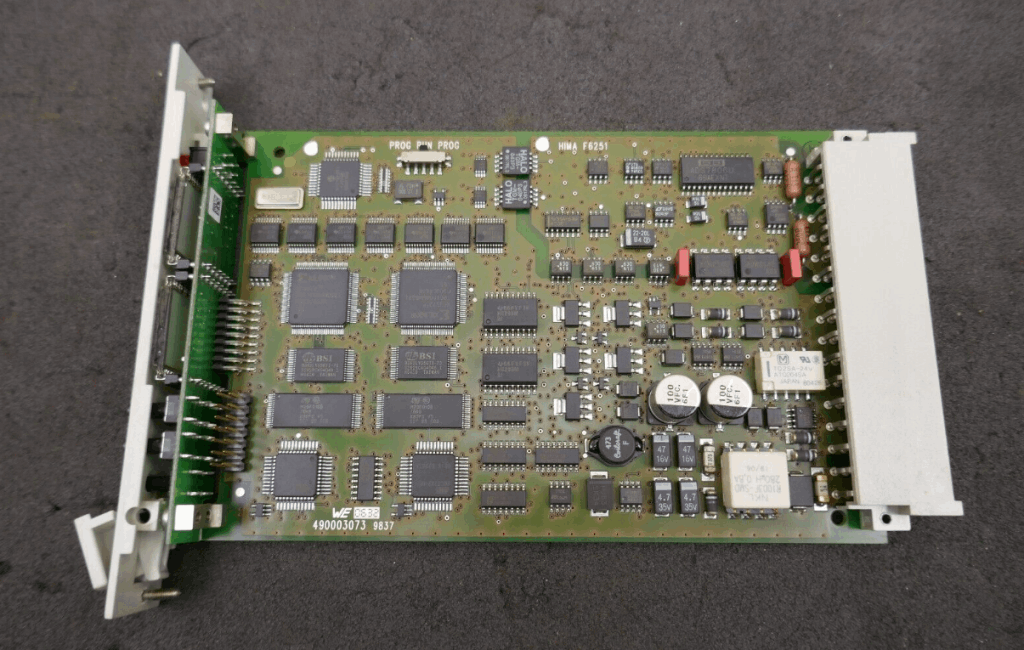

The HIMA F35 011 is a safety-related controller from the renowned F-series platform, developed by HIMA – a global leader in functional safety and automation solutions. Designed specifically for safety-critical applications, the F35 011 operates as a programmable logic controller (PLC) certified up to SIL 3 in accordance with IEC 61508.

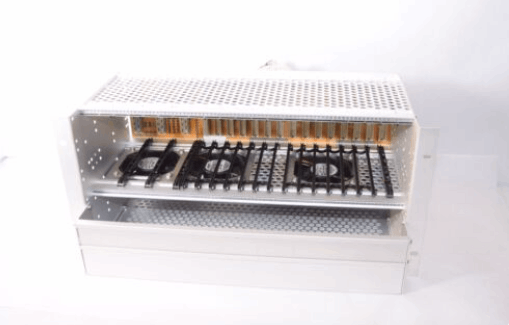

This controller combines robust safety functionality with real-time performance and modular flexibility, making it a central element in distributed and scalable safety systems. Whether deployed in power generation, oil & gas, petrochemical plants, or railway applications, the F35 011 ensures maximum system integrity and uninterrupted safe operation under all conditions.

Its dual-processor architecture, fault-tolerant design, and support for hot-redundant configurations deliver high availability with no compromise on functional safety.

Product Specifications

| Parameter | Details |

|---|---|

| Model | HIMA F35 011 |

| Series | HIMA F-Series Safety Controllers |

| Controller Type | Safety-Related Programmable Logic Controller |

| Compliance Standards | IEC 61508, SIL 3 / EN 50156, EN 50129 |

| CPU Architecture | Dual Processor Redundant Architecture |

| Memory | 4 MB Flash, 1 MB RAM |

| Cycle Time | < 10 ms (typical) |

| Communication Protocols | Ethernet, RS232, PROFIBUS, F-Net, Modbus TCP |

| I/O Support | Up to 256 local I/O, expandable via F-Rail |

| Operating Temperature | -20°C to +60°C |

| Power Supply | 24 VDC (18 V to 30 V range) |

| Housing Material | Industrial-grade aluminum casing |

| Cooling Method | Passive convection |

| Dimensions (L × W × H) | 257 x 114 x 97 mm |

| Weight | 1.2 kg |

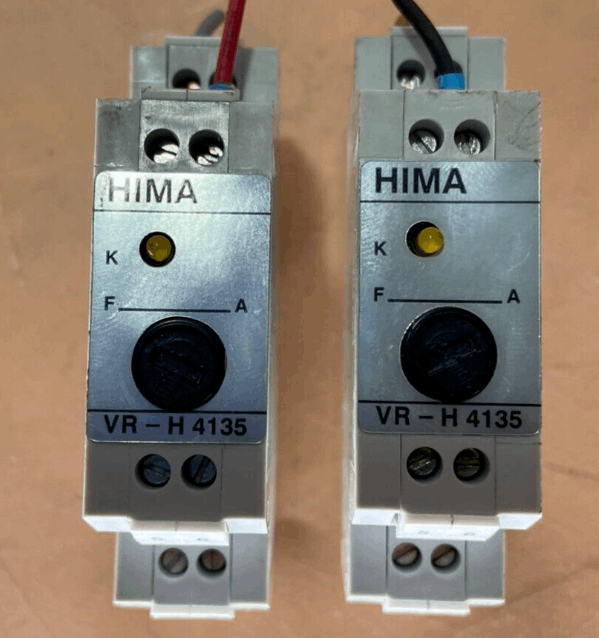

| Mounting | DIN Rail |

| Diagnostic Capability | Full system self-diagnostics with logging |

| Programming Interface | SILworX Engineering Tool |

Product Applications

The HIMA F35 011 controller is engineered to function as the core brain of safety-critical systems across a diverse set of industries. Its applications include:

Process Safety Systems (PSS): In chemical, oil & gas, and refinery plants, the F35 011 executes emergency shutdown (ESD), burner management, and fire & gas systems.

Power Plant Safety: Used in both conventional and nuclear power generation for boiler protection and turbine overspeed controls.

Railway Automation: Controls signaling, interlocking, and train protection systems compliant with EN 50129.

Offshore Platforms: Operates reliably in marine and offshore environments where system integrity is essential.

Manufacturing Plants: Ensures the safety of machinery, personnel, and equipment in complex production lines.

Distributed Safety Networks: Suitable for remote and networked safety installations with F-NET/F-Rail bus expansion.

Product Advantages

Certified SIL 3 Safety: Full compliance with international safety standards, offering peace of mind in high-risk installations.

Redundant Architecture: Dual-CPU and communication redundancy ensure system availability even in failure scenarios.

Modular Expansion: Flexibly expandable I/O and communication options accommodate plant evolution without major redesign.

High-Speed Processing: Fast cycle times enable timely response in critical operations and emergency scenarios.

Diagnostics & Maintenance: Built-in self-diagnostics and integrated logging tools simplify troubleshooting and predictive maintenance.

Harsh Environment Ready: Designed to perform reliably in environments with high vibration, temperature variation, and electrical noise.

Engineering Integration: Seamless programming using SILworX software for configuration, testing, and validation.

Compact Footprint: Saves panel space while delivering maximum control capability and reliability.

Interoperability: Supports common fieldbus and communication standards for integration into both legacy and modern systems.

Long Lifecycle Support: Backed by HIMA’s long-term support policy and extensive global service network.

FAQ

What safety standard is the HIMA F35 011 certified for?

The F35 011 is certified for SIL 3 according to IEC 61508, ensuring it can be used in high-integrity safety systems.

Can the F35 011 be used in redundant systems?

Yes, the F35 011 supports hot standby redundancy and dual CPU configurations for high availability.

What programming tool is required to configure the F35 011?

It uses SILworX, HIMA’s standard IEC 61131-compliant engineering tool.

Does the F35 011 support remote I/O?

Yes, it can expand to remote I/O using F-Rail or other HIMA-supported communication modules.

What are the power supply requirements for the F35 011?

It operates on a 24 VDC power supply, with a voltage tolerance range of 18 V to 30 V.

How many I/O points can the F35 011 handle?

It supports up to 256 I/O points locally, with options for remote expansion.

Is it suitable for marine or offshore installations?

Yes, the controller’s rugged design and extended temperature range make it suitable for offshore and maritime use.

What communication protocols are supported?

It supports Ethernet, PROFIBUS, RS232, Modbus TCP, and HIMA’s F-NET.

How is the unit mounted?

The F35 011 is DIN rail mountable, facilitating easy panel integration.

What kind of diagnostics are available?

The module includes full system self-check, event logging, and diagnostic messaging to ensure early fault detection.

Hima F35 011 Safety Related Controller

Manufacturer:HIMA

Product Number:F35 011

Product Type:Safety Related Controller

Origin:Germany

Dimensions:257 x 114 x 97 mm

Weight:1.2 kg

Views:47

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The HIMA F35 011 is a safety-related controller from the renowned F-series platform, developed by HIMA – a global leader in functional safety and automation solutions. Designed specifically for safety-critical applications, the F35 011 operates as a programmable logic controller (PLC) certified up to SIL 3 in accordance with IEC 61508.

This controller combines robust safety functionality with real-time performance and modular flexibility, making it a central element in distributed and scalable safety systems. Whether deployed in power generation, oil & gas, petrochemical plants, or railway applications, the F35 011 ensures maximum system integrity and uninterrupted safe operation under all conditions.

Its dual-processor architecture, fault-tolerant design, and support for hot-redundant configurations deliver high availability with no compromise on functional safety.

Product Specifications

| Parameter | Details |

|---|---|

| Model | HIMA F35 011 |

| Series | HIMA F-Series Safety Controllers |

| Controller Type | Safety-Related Programmable Logic Controller |

| Compliance Standards | IEC 61508, SIL 3 / EN 50156, EN 50129 |

| CPU Architecture | Dual Processor Redundant Architecture |

| Memory | 4 MB Flash, 1 MB RAM |

| Cycle Time | < 10 ms (typical) |

| Communication Protocols | Ethernet, RS232, PROFIBUS, F-Net, Modbus TCP |

| I/O Support | Up to 256 local I/O, expandable via F-Rail |

| Operating Temperature | -20°C to +60°C |

| Power Supply | 24 VDC (18 V to 30 V range) |

| Housing Material | Industrial-grade aluminum casing |

| Cooling Method | Passive convection |

| Dimensions (L × W × H) | 257 x 114 x 97 mm |

| Weight | 1.2 kg |

| Mounting | DIN Rail |

| Diagnostic Capability | Full system self-diagnostics with logging |

| Programming Interface | SILworX Engineering Tool |

Product Applications

The HIMA F35 011 controller is engineered to function as the core brain of safety-critical systems across a diverse set of industries. Its applications include:

Process Safety Systems (PSS): In chemical, oil & gas, and refinery plants, the F35 011 executes emergency shutdown (ESD), burner management, and fire & gas systems.

Power Plant Safety: Used in both conventional and nuclear power generation for boiler protection and turbine overspeed controls.

Railway Automation: Controls signaling, interlocking, and train protection systems compliant with EN 50129.

Offshore Platforms: Operates reliably in marine and offshore environments where system integrity is essential.

Manufacturing Plants: Ensures the safety of machinery, personnel, and equipment in complex production lines.

Distributed Safety Networks: Suitable for remote and networked safety installations with F-NET/F-Rail bus expansion.

Product Advantages

Certified SIL 3 Safety: Full compliance with international safety standards, offering peace of mind in high-risk installations.

Redundant Architecture: Dual-CPU and communication redundancy ensure system availability even in failure scenarios.

Modular Expansion: Flexibly expandable I/O and communication options accommodate plant evolution without major redesign.

High-Speed Processing: Fast cycle times enable timely response in critical operations and emergency scenarios.

Diagnostics & Maintenance: Built-in self-diagnostics and integrated logging tools simplify troubleshooting and predictive maintenance.

Harsh Environment Ready: Designed to perform reliably in environments with high vibration, temperature variation, and electrical noise.

Engineering Integration: Seamless programming using SILworX software for configuration, testing, and validation.

Compact Footprint: Saves panel space while delivering maximum control capability and reliability.

Interoperability: Supports common fieldbus and communication standards for integration into both legacy and modern systems.

Long Lifecycle Support: Backed by HIMA’s long-term support policy and extensive global service network.

FAQ

What safety standard is the HIMA F35 011 certified for?

The F35 011 is certified for SIL 3 according to IEC 61508, ensuring it can be used in high-integrity safety systems.

Can the F35 011 be used in redundant systems?

Yes, the F35 011 supports hot standby redundancy and dual CPU configurations for high availability.

What programming tool is required to configure the F35 011?

It uses SILworX, HIMA’s standard IEC 61131-compliant engineering tool.

Does the F35 011 support remote I/O?

Yes, it can expand to remote I/O using F-Rail or other HIMA-supported communication modules.

What are the power supply requirements for the F35 011?

It operates on a 24 VDC power supply, with a voltage tolerance range of 18 V to 30 V.

How many I/O points can the F35 011 handle?

It supports up to 256 I/O points locally, with options for remote expansion.

Is it suitable for marine or offshore installations?

Yes, the controller’s rugged design and extended temperature range make it suitable for offshore and maritime use.

What communication protocols are supported?

It supports Ethernet, PROFIBUS, RS232, Modbus TCP, and HIMA’s F-NET.

How is the unit mounted?

The F35 011 is DIN rail mountable, facilitating easy panel integration.

What kind of diagnostics are available?

The module includes full system self-check, event logging, and diagnostic messaging to ensure early fault detection.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...