Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

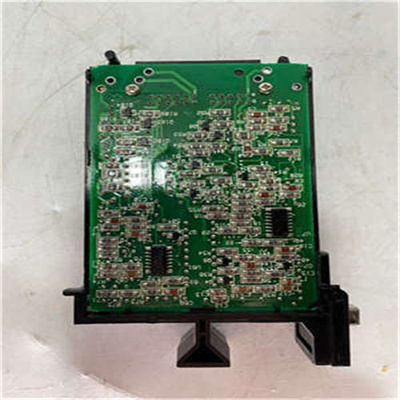

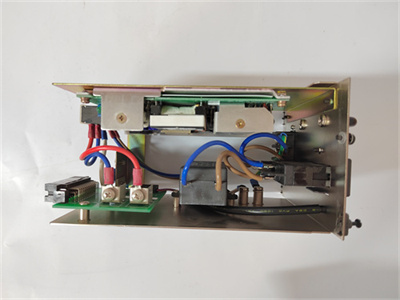

Yokogawa CP461-10 S1 Processor Module

Manufacturer:Yokogawa

Product Number:CP461-10 S1

Product Type:Processor Module

Origin:Japan

Dimensions:32.8 x 149 x 199.5 mm

Weight:0.7 kg

Views:70

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa CP461-10 S1 Processor Module is a central control unit used within the CENTUM VP integrated production control system, developed by Yokogawa. This module serves as the primary processing unit in a Field Control Station (FCS), executing user-defined control logic, managing communications between field devices and human-machine interfaces (HMI), and ensuring real-time and highly reliable operation across plant networks.

Designed for industrial-grade performance, the CP461-10 S1 features advanced CPU architecture, high-speed processing, and robust fault-tolerant mechanisms. It is a preferred solution for critical process automation in industries that demand uninterrupted operations and deterministic control. The module’s backward compatibility and scalable configuration make it highly suitable for both greenfield and retrofit projects in sectors like oil & gas, petrochemicals, chemicals, power, and pharmaceuticals.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | CP461-10 S1 |

| Manufacturer | Yokogawa Electric Corporation |

| Product Type | FCS Processor Module (CPU Unit) |

| Series | CENTUM VP |

| Processor Type | High-performance 32-bit microprocessor |

| Memory Capacity | 128 MB DRAM, 32 MB Flash ROM |

| I/O Capacity | Up to 50,000 points (with distributed I/O) |

| Supported Protocols | Vnet/IP, FCS Bus, Ethernet |

| Redundancy | Fully supported (dual configuration available) |

| Mounting Style | Rack-mounted via FCS base unit |

| Power Supply | 24 VDC (via backplane) |

| Operating Temperature | 0°C to +55°C |

| Storage Temperature | -20°C to +70°C |

| Humidity Range | 5% to 95% RH (non-condensing) |

| Dimensions (L × W × H) | 32.8 x 149 x 199.5 mm |

| Weight | 0.7 kg |

| Certifications | CE, RoHS, KC, EN61000, ISA, G3 conformant |

Product Applications

The CP461-10 S1 is built to meet the demanding requirements of continuous and batch process industries. Common applications include:

Oil & Gas: Controls refineries, upstream well pads, offshore platforms, and gas plants.

Petrochemical Plants: Executes safety and process logic across distillation, cracking, and blending units.

Power Generation: Oversees boiler controls, turbine speed regulation, auxiliary systems, and load balancing.

Pharmaceutical Manufacturing: Supports GMP/21 CFR Part 11-compliant automation with precise and validated control.

Chemical Processing: Used in polymer, fertilizer, and specialty chemical production requiring advanced control algorithms.

Water Treatment Facilities: Automates filtration, chlorination, and distribution operations across large facilities.

Product Advantages

High-Speed Processing: Optimized for real-time control with high-speed CPU and memory performance.

Scalability: Supports thousands of I/O points and easy integration of remote I/O, making it ideal for small to large-scale systems.

Redundant Architecture: Offers dual-redundancy for fault tolerance and uninterrupted plant operation.

Secure Communication: Built-in support for Vnet/IP ensures reliable and secure data transmission across distributed control elements.

Longevity and Compatibility: Backward-compatible with older Yokogawa systems, reducing total lifecycle cost.

Ease of Maintenance: Diagnostic features and modular design reduce downtime during troubleshooting or upgrades.

Compliance with Global Standards: Certified for use in regulated environments with international standards (RoHS, CE, ISA).

Stable in Harsh Environments: G3 compliance ensures it withstands corrosive gases, making it suitable for rugged plant environments.

Frequently Asked Questions (FAQ)

What DCS platform is the CP461-10 S1 compatible with?

The CP461-10 S1 is compatible with the CENTUM VP system, Yokogawa’s flagship distributed control platform.

Does the CP461-10 S1 support redundancy?

Yes, the module supports full CPU redundancy, enabling seamless failover in case of hardware issues.

Can this module handle large-scale I/O configurations?

Absolutely. It can manage up to 50,000 I/O points using remote and distributed I/O architecture.

Is the CP461-10 S1 suitable for use in hazardous environments?

While not intrinsically safe itself, it can be deployed in hazardous zones when installed in certified protective enclosures.

Can firmware updates be performed in the field?

Yes. Firmware can be safely updated via Yokogawa’s engineering tools during scheduled maintenance.

Is the module hot-swappable?

Not directly, but when used in a redundant setup, the standby module can be replaced without stopping operations.

What communication protocols are supported?

The module supports Vnet/IP, Ethernet, and proprietary FCS Bus for robust system integration.

What is the typical lifespan of the CP461-10 S1?

With proper installation and regular diagnostics, it can operate reliably for 10–15 years or longer.

Can this module be used for batch control?

Yes, it supports sequential and batch control logic often required in the pharmaceutical and chemical industries.

How does it differ from CP451 series modules?

The CP461-10 S1 features enhanced processing speed, more memory, and greater I/O handling, making it ideal for larger and more complex automation tasks.

Yokogawa CP461-10 S1 Processor Module

Manufacturer:Yokogawa

Product Number:CP461-10 S1

Product Type:Processor Module

Origin:Japan

Dimensions:32.8 x 149 x 199.5 mm

Weight:0.7 kg

Views:70

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa CP461-10 S1 Processor Module is a central control unit used within the CENTUM VP integrated production control system, developed by Yokogawa. This module serves as the primary processing unit in a Field Control Station (FCS), executing user-defined control logic, managing communications between field devices and human-machine interfaces (HMI), and ensuring real-time and highly reliable operation across plant networks.

Designed for industrial-grade performance, the CP461-10 S1 features advanced CPU architecture, high-speed processing, and robust fault-tolerant mechanisms. It is a preferred solution for critical process automation in industries that demand uninterrupted operations and deterministic control. The module’s backward compatibility and scalable configuration make it highly suitable for both greenfield and retrofit projects in sectors like oil & gas, petrochemicals, chemicals, power, and pharmaceuticals.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | CP461-10 S1 |

| Manufacturer | Yokogawa Electric Corporation |

| Product Type | FCS Processor Module (CPU Unit) |

| Series | CENTUM VP |

| Processor Type | High-performance 32-bit microprocessor |

| Memory Capacity | 128 MB DRAM, 32 MB Flash ROM |

| I/O Capacity | Up to 50,000 points (with distributed I/O) |

| Supported Protocols | Vnet/IP, FCS Bus, Ethernet |

| Redundancy | Fully supported (dual configuration available) |

| Mounting Style | Rack-mounted via FCS base unit |

| Power Supply | 24 VDC (via backplane) |

| Operating Temperature | 0°C to +55°C |

| Storage Temperature | -20°C to +70°C |

| Humidity Range | 5% to 95% RH (non-condensing) |

| Dimensions (L × W × H) | 32.8 x 149 x 199.5 mm |

| Weight | 0.7 kg |

| Certifications | CE, RoHS, KC, EN61000, ISA, G3 conformant |

Product Applications

The CP461-10 S1 is built to meet the demanding requirements of continuous and batch process industries. Common applications include:

Oil & Gas: Controls refineries, upstream well pads, offshore platforms, and gas plants.

Petrochemical Plants: Executes safety and process logic across distillation, cracking, and blending units.

Power Generation: Oversees boiler controls, turbine speed regulation, auxiliary systems, and load balancing.

Pharmaceutical Manufacturing: Supports GMP/21 CFR Part 11-compliant automation with precise and validated control.

Chemical Processing: Used in polymer, fertilizer, and specialty chemical production requiring advanced control algorithms.

Water Treatment Facilities: Automates filtration, chlorination, and distribution operations across large facilities.

Product Advantages

High-Speed Processing: Optimized for real-time control with high-speed CPU and memory performance.

Scalability: Supports thousands of I/O points and easy integration of remote I/O, making it ideal for small to large-scale systems.

Redundant Architecture: Offers dual-redundancy for fault tolerance and uninterrupted plant operation.

Secure Communication: Built-in support for Vnet/IP ensures reliable and secure data transmission across distributed control elements.

Longevity and Compatibility: Backward-compatible with older Yokogawa systems, reducing total lifecycle cost.

Ease of Maintenance: Diagnostic features and modular design reduce downtime during troubleshooting or upgrades.

Compliance with Global Standards: Certified for use in regulated environments with international standards (RoHS, CE, ISA).

Stable in Harsh Environments: G3 compliance ensures it withstands corrosive gases, making it suitable for rugged plant environments.

Frequently Asked Questions (FAQ)

What DCS platform is the CP461-10 S1 compatible with?

The CP461-10 S1 is compatible with the CENTUM VP system, Yokogawa’s flagship distributed control platform.

Does the CP461-10 S1 support redundancy?

Yes, the module supports full CPU redundancy, enabling seamless failover in case of hardware issues.

Can this module handle large-scale I/O configurations?

Absolutely. It can manage up to 50,000 I/O points using remote and distributed I/O architecture.

Is the CP461-10 S1 suitable for use in hazardous environments?

While not intrinsically safe itself, it can be deployed in hazardous zones when installed in certified protective enclosures.

Can firmware updates be performed in the field?

Yes. Firmware can be safely updated via Yokogawa’s engineering tools during scheduled maintenance.

Is the module hot-swappable?

Not directly, but when used in a redundant setup, the standby module can be replaced without stopping operations.

What communication protocols are supported?

The module supports Vnet/IP, Ethernet, and proprietary FCS Bus for robust system integration.

What is the typical lifespan of the CP461-10 S1?

With proper installation and regular diagnostics, it can operate reliably for 10–15 years or longer.

Can this module be used for batch control?

Yes, it supports sequential and batch control logic often required in the pharmaceutical and chemical industries.

How does it differ from CP451 series modules?

The CP461-10 S1 features enhanced processing speed, more memory, and greater I/O handling, making it ideal for larger and more complex automation tasks.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...