Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

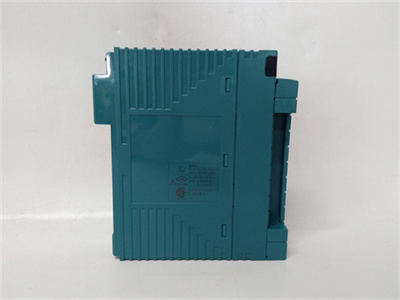

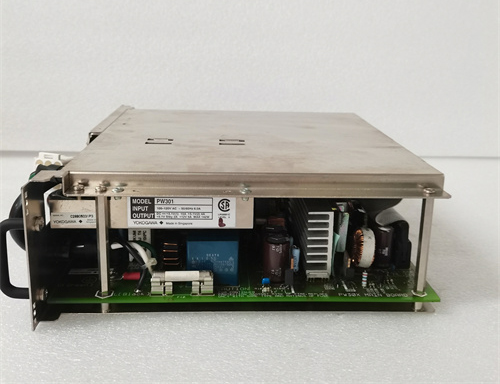

Yokogawa SSC50D-F2121 Duplex Safety Control Unit

Manufacturer:Yokogawa

Product Number:SSC50D-F2121

Product Type:Duplex Safety Control Unit

Origin:Japan

Dimensions:482.6 x 399.2 x 264.4 mm

Weight:13kg

Views:18

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa SSC50D-F2121 Duplex Safety Control Unit is a high-end safety controller built for mission-critical industrial safety systems. As part of Yokogawa’s advanced ProSafe-RS platform, this unit offers high-performance duplex architecture, providing unparalleled reliability and continuous operation for safety instrumented systems (SIS) in demanding environments.

Engineered with precision and efficiency, the SSC50D-F2121 ensures high availability and fault tolerance, minimizing downtime even during unexpected failures or scheduled maintenance. It integrates seamlessly into complex plant infrastructures, making it an ideal solution for industries such as oil and gas, power generation, petrochemical, and large-scale manufacturing.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | Yokogawa SSC50D-F2121 |

| Type | Duplex Safety Control Unit |

| Architecture | Duplex redundancy with synchronized failover |

| Communication Interfaces | Vnet/IP, ESB bus, Optical Fiber |

| Power Supply | 24 VDC |

| Power Consumption | Approx. 120 W |

| Operating Temperature | 0°C to 55°C |

| Operating Humidity | 10% to 90% RH (non-condensing) |

| Compliance | IEC 61508, SIL 3 certified |

| Protection Level | IP20 |

| Diagnostic Functions | Real-time fault detection and predictive analysis |

| Dimensions | 482.6 x 399.2 x 264.4 mm |

| Weight | 13 kg |

Applications

The SSC50D-F2121 supports a wide range of industrial applications where safety and uptime are essential:

Oil and Gas – Emergency shutdown (ESD) systems, fire and gas detection, pipeline monitoring, and wellhead control.

Power Generation – Turbine and boiler safety management, auxiliary system controls, and fail-safe shutdowns.

Chemical and Petrochemical Plants – Process automation with real-time safety oversight for hazardous operations.

Pharmaceutical Manufacturing – Ensuring safety in regulated environments during automated batch processing.

Water and Wastewater Treatment – Continuous monitoring and safety response for large-scale facilities.

Heavy Industry and Mining – Protecting critical assets and personnel in high-risk, high-load operations.

Advantages

The Yokogawa SSC50D-F2121 delivers industry-leading performance and flexibility, making it a top choice for safety automation solutions:

Advanced Duplex Architecture – Dual redundant controllers ensure continuous, fail-safe operation without interruptions.

Enhanced Processing Power – High-speed processing for complex safety applications and multi-node environments.

Seamless Integration – Fully compatible with ProSafe-RS and CENTUM VP systems for efficient plant-wide integration.

Robust Compliance – Certified for IEC 61508 SIL 3, meeting the most stringent global safety standards.

Comprehensive Diagnostics – Predictive maintenance and real-time fault detection minimize unplanned downtime.

Flexible Scalability – Modular design supports expansions and system upgrades without major redesigns.

User-Friendly Configuration – Intuitive engineering tools reduce commissioning and maintenance complexity.

Durability – Built to withstand demanding industrial environments and harsh operating conditions.

Lifecycle Support – Backed by Yokogawa’s extensive global service network for ongoing technical assistance.

FAQ

Q1: What communication protocols are supported by the SSC50D-F2121?

A1: The SSC50D-F2121 supports Vnet/IP, ESB bus, and optical fiber interfaces, ensuring fast and secure data transmission.

Q2: How does the duplex design enhance reliability?

A2: The duplex configuration allows real-time redundancy, automatically switching to the backup system in the event of a primary unit failure.

Q3: Is the SSC50D-F2121 compatible with other Yokogawa platforms?

A3: Yes, it integrates seamlessly with both CENTUM VP and ProSafe-RS systems.

Q4: What safety certifications does this unit meet?

A4: It is IEC 61508 SIL 3 certified, ensuring compliance with international safety integrity standards.

Q5: Can the controller handle large-scale safety applications?

A5: Absolutely, its high-speed processors and modular design make it suitable for complex, multi-node configurations.

Q6: What diagnostic capabilities are built into the unit?

A6: It offers real-time fault detection, predictive analytics, and automated event logging for faster troubleshooting.

Q7: Can this unit be scaled for system expansions?

A7: Yes, its modular architecture supports scalable configurations, accommodating future growth.

Q8: How does it ensure minimal downtime during maintenance?

A8: The duplex system allows online maintenance, ensuring continuous operation while updates or repairs are performed.

Q9: What is the maximum environmental range supported by this unit?

A9: It operates reliably between 0°C and 55°C with humidity levels from 10% to 90% RH (non-condensing).

Q10: Who should I contact for system configuration or troubleshooting?

A10: Please contact our customer service team for expert technical assistance and support.

Yokogawa SSC50D-F2121 Duplex Safety Control Unit

Manufacturer:Yokogawa

Product Number:SSC50D-F2121

Product Type:Duplex Safety Control Unit

Origin:Japan

Dimensions:482.6 x 399.2 x 264.4 mm

Weight:13kg

Views:18

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa SSC50D-F2121 Duplex Safety Control Unit is a high-end safety controller built for mission-critical industrial safety systems. As part of Yokogawa’s advanced ProSafe-RS platform, this unit offers high-performance duplex architecture, providing unparalleled reliability and continuous operation for safety instrumented systems (SIS) in demanding environments.

Engineered with precision and efficiency, the SSC50D-F2121 ensures high availability and fault tolerance, minimizing downtime even during unexpected failures or scheduled maintenance. It integrates seamlessly into complex plant infrastructures, making it an ideal solution for industries such as oil and gas, power generation, petrochemical, and large-scale manufacturing.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | Yokogawa SSC50D-F2121 |

| Type | Duplex Safety Control Unit |

| Architecture | Duplex redundancy with synchronized failover |

| Communication Interfaces | Vnet/IP, ESB bus, Optical Fiber |

| Power Supply | 24 VDC |

| Power Consumption | Approx. 120 W |

| Operating Temperature | 0°C to 55°C |

| Operating Humidity | 10% to 90% RH (non-condensing) |

| Compliance | IEC 61508, SIL 3 certified |

| Protection Level | IP20 |

| Diagnostic Functions | Real-time fault detection and predictive analysis |

| Dimensions | 482.6 x 399.2 x 264.4 mm |

| Weight | 13 kg |

Applications

The SSC50D-F2121 supports a wide range of industrial applications where safety and uptime are essential:

Oil and Gas – Emergency shutdown (ESD) systems, fire and gas detection, pipeline monitoring, and wellhead control.

Power Generation – Turbine and boiler safety management, auxiliary system controls, and fail-safe shutdowns.

Chemical and Petrochemical Plants – Process automation with real-time safety oversight for hazardous operations.

Pharmaceutical Manufacturing – Ensuring safety in regulated environments during automated batch processing.

Water and Wastewater Treatment – Continuous monitoring and safety response for large-scale facilities.

Heavy Industry and Mining – Protecting critical assets and personnel in high-risk, high-load operations.

Advantages

The Yokogawa SSC50D-F2121 delivers industry-leading performance and flexibility, making it a top choice for safety automation solutions:

Advanced Duplex Architecture – Dual redundant controllers ensure continuous, fail-safe operation without interruptions.

Enhanced Processing Power – High-speed processing for complex safety applications and multi-node environments.

Seamless Integration – Fully compatible with ProSafe-RS and CENTUM VP systems for efficient plant-wide integration.

Robust Compliance – Certified for IEC 61508 SIL 3, meeting the most stringent global safety standards.

Comprehensive Diagnostics – Predictive maintenance and real-time fault detection minimize unplanned downtime.

Flexible Scalability – Modular design supports expansions and system upgrades without major redesigns.

User-Friendly Configuration – Intuitive engineering tools reduce commissioning and maintenance complexity.

Durability – Built to withstand demanding industrial environments and harsh operating conditions.

Lifecycle Support – Backed by Yokogawa’s extensive global service network for ongoing technical assistance.

FAQ

Q1: What communication protocols are supported by the SSC50D-F2121?

A1: The SSC50D-F2121 supports Vnet/IP, ESB bus, and optical fiber interfaces, ensuring fast and secure data transmission.

Q2: How does the duplex design enhance reliability?

A2: The duplex configuration allows real-time redundancy, automatically switching to the backup system in the event of a primary unit failure.

Q3: Is the SSC50D-F2121 compatible with other Yokogawa platforms?

A3: Yes, it integrates seamlessly with both CENTUM VP and ProSafe-RS systems.

Q4: What safety certifications does this unit meet?

A4: It is IEC 61508 SIL 3 certified, ensuring compliance with international safety integrity standards.

Q5: Can the controller handle large-scale safety applications?

A5: Absolutely, its high-speed processors and modular design make it suitable for complex, multi-node configurations.

Q6: What diagnostic capabilities are built into the unit?

A6: It offers real-time fault detection, predictive analytics, and automated event logging for faster troubleshooting.

Q7: Can this unit be scaled for system expansions?

A7: Yes, its modular architecture supports scalable configurations, accommodating future growth.

Q8: How does it ensure minimal downtime during maintenance?

A8: The duplex system allows online maintenance, ensuring continuous operation while updates or repairs are performed.

Q9: What is the maximum environmental range supported by this unit?

A9: It operates reliably between 0°C and 55°C with humidity levels from 10% to 90% RH (non-condensing).

Q10: Who should I contact for system configuration or troubleshooting?

A10: Please contact our customer service team for expert technical assistance and support.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...