Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

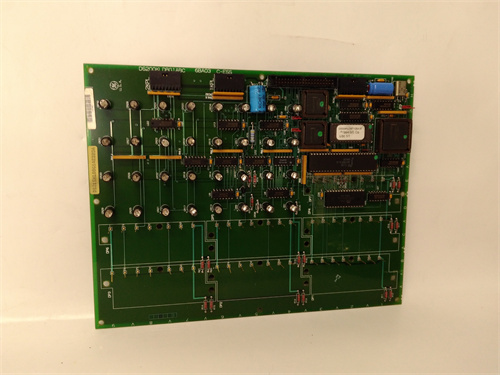

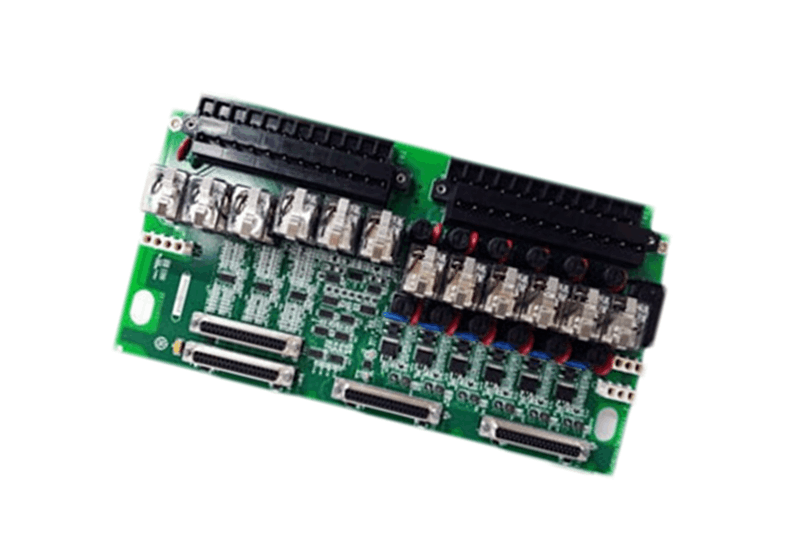

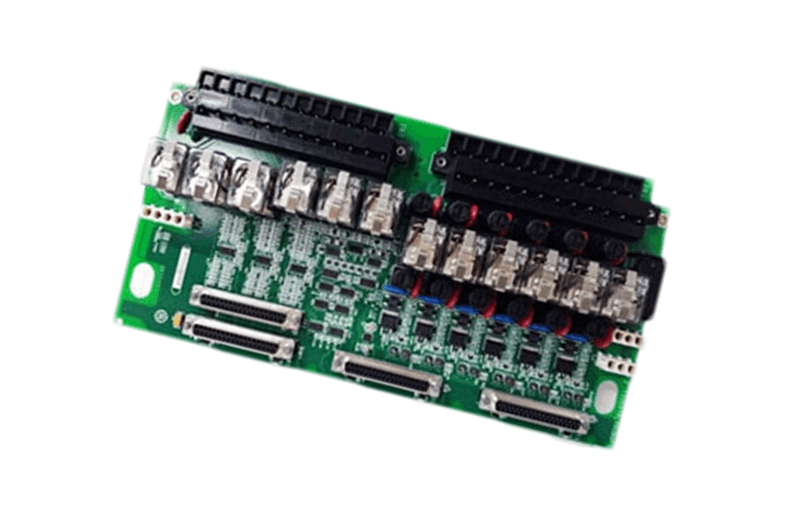

General Electric IS200PRTDH1A RTD Terminal Board

Manufacturer:GE

Product Number:IS200PRTDH1A

Product Type:RTD Terminal Board

Origin:USA

Dimensions:260 × 120 × 35 mm

Weight:0.8 kg

Views:22

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200PRTDH1A RTD Terminal Board is a precision input interface board designed for temperature sensing in GE Mark VI and Mark VIe control systems. It provides reliable connections for multiple Resistance Temperature Detectors (RTDs), ensuring accurate measurement of turbine and generator component temperatures. By offering robust signal conditioning, high-integrity shielding, and seamless integration with GE’s control platforms, the IS200PRTDH1A helps operators monitor critical equipment and maintain optimal operating conditions in power generation and industrial applications.

Product Specifications

| Parameter | Description |

|---|---|

| Model | GE IS200PRTDH1A RTD Terminal Board |

| Primary Function | Interfaces multiple RTD sensors with Mark VI/VIe controllers |

| Supported RTD Types | 100 Ω Platinum (Pt100), 120 Ω Nickel, and other standard 3-wire RTDs |

| Number of Channels | Up to 16 RTD inputs |

| Input Voltage | 24 V DC nominal (18–30 V DC operating range) |

| Signal Conditioning | Precision instrumentation amplifiers with cold-junction compensation |

| Measurement Accuracy | ±0.1 °C typical |

| Isolation Voltage | 2500 V RMS channel-to-ground |

| Operating Temperature | –20 °C to +65 °C |

| Cooling | Natural convection (forced air optional) |

| Dimensions | 260 × 120 × 35 mm |

| Weight | 0.8 kg |

| Compliance | CE, UL, and RoHS |

| Protection Features | ESD suppression, over-voltage protection, and hot-swap capability |

Applications

-

Turbine Temperature Monitoring – Continuous sensing of bearing, rotor, and casing temperatures in gas, steam, and hydro turbines.

-

Generator Stator and Rotor Monitoring – Precise measurement of winding and core temperatures to prevent overheating.

-

Industrial Process Control – Accurate temperature feedback for chemical plants, refineries, and paper mills.

-

Retrofit Projects – Upgrading older systems for improved accuracy and reliability within existing Mark VI or Mark VIe installations.

Advantages

-

High Accuracy – Advanced signal conditioning ensures stable and precise temperature readings across all channels.

-

Flexible Sensor Support – Compatible with common RTD types, enabling easy integration with existing sensors.

-

Robust Isolation – 2500 V RMS isolation protects control electronics from high-voltage transients.

-

Maintenance Friendly – Hot-swap design allows quick replacement without system downtime.

-

Noise Immunity – Shielded inputs and differential measurement minimize electrical interference in harsh industrial environments.

-

Direct Integration – Seamlessly connects to GE Mark VI/VIe controllers for fast commissioning and minimal wiring complexity.

FAQ

-

How many RTD sensors can the IS200PRTDH1A support simultaneously?

It accommodates up to 16 three-wire RTD inputs, each with independent signal conditioning and isolation.

-

Which RTD standards are compatible with this board?

It supports Pt100 (IEC 751), 120 Ω Nickel, and other industry-standard RTDs commonly used in turbine and generator monitoring.

-

How is channel-to-channel isolation achieved?

Isolation is provided through high-quality differential amplifiers and opto-coupled circuitry rated at 2500 V RMS.

-

What is the typical measurement accuracy?

The board delivers temperature accuracy of approximately ±0.1 °C when used with calibrated RTDs.

-

Does the board provide cold-junction compensation?

Yes, integrated cold-junction circuitry ensures precise readings despite ambient temperature fluctuations.

-

Is the board hot-swappable?

Yes, it can be inserted or removed while the system remains energized, enabling rapid maintenance or replacement.

-

What kind of shielding is required for sensor cabling?

Twisted, shielded three-wire cables are recommended to maintain noise immunity over long cable runs.

-

How does the board handle open or shorted RTD inputs?

Built-in diagnostics detect sensor faults and report them to the Mark VI/VIe controller for quick troubleshooting.

-

What is the maximum cable length supported for each RTD channel?

Up to 100 m of shielded cable can be used per channel without compromising accuracy, provided proper wiring practices are followed.

-

How are temperature measurements communicated to the control system?

Conditioned analog signals are digitized and transmitted via the Mark VI/VIe high-speed proprietary control bus.

General Electric IS200PRTDH1A RTD Terminal Board

Manufacturer:GE

Product Number:IS200PRTDH1A

Product Type:RTD Terminal Board

Origin:USA

Dimensions:260 × 120 × 35 mm

Weight:0.8 kg

Views:22

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200PRTDH1A RTD Terminal Board is a precision input interface board designed for temperature sensing in GE Mark VI and Mark VIe control systems. It provides reliable connections for multiple Resistance Temperature Detectors (RTDs), ensuring accurate measurement of turbine and generator component temperatures. By offering robust signal conditioning, high-integrity shielding, and seamless integration with GE’s control platforms, the IS200PRTDH1A helps operators monitor critical equipment and maintain optimal operating conditions in power generation and industrial applications.

Product Specifications

| Parameter | Description |

|---|---|

| Model | GE IS200PRTDH1A RTD Terminal Board |

| Primary Function | Interfaces multiple RTD sensors with Mark VI/VIe controllers |

| Supported RTD Types | 100 Ω Platinum (Pt100), 120 Ω Nickel, and other standard 3-wire RTDs |

| Number of Channels | Up to 16 RTD inputs |

| Input Voltage | 24 V DC nominal (18–30 V DC operating range) |

| Signal Conditioning | Precision instrumentation amplifiers with cold-junction compensation |

| Measurement Accuracy | ±0.1 °C typical |

| Isolation Voltage | 2500 V RMS channel-to-ground |

| Operating Temperature | –20 °C to +65 °C |

| Cooling | Natural convection (forced air optional) |

| Dimensions | 260 × 120 × 35 mm |

| Weight | 0.8 kg |

| Compliance | CE, UL, and RoHS |

| Protection Features | ESD suppression, over-voltage protection, and hot-swap capability |

Applications

-

Turbine Temperature Monitoring – Continuous sensing of bearing, rotor, and casing temperatures in gas, steam, and hydro turbines.

-

Generator Stator and Rotor Monitoring – Precise measurement of winding and core temperatures to prevent overheating.

-

Industrial Process Control – Accurate temperature feedback for chemical plants, refineries, and paper mills.

-

Retrofit Projects – Upgrading older systems for improved accuracy and reliability within existing Mark VI or Mark VIe installations.

Advantages

-

High Accuracy – Advanced signal conditioning ensures stable and precise temperature readings across all channels.

-

Flexible Sensor Support – Compatible with common RTD types, enabling easy integration with existing sensors.

-

Robust Isolation – 2500 V RMS isolation protects control electronics from high-voltage transients.

-

Maintenance Friendly – Hot-swap design allows quick replacement without system downtime.

-

Noise Immunity – Shielded inputs and differential measurement minimize electrical interference in harsh industrial environments.

-

Direct Integration – Seamlessly connects to GE Mark VI/VIe controllers for fast commissioning and minimal wiring complexity.

FAQ

-

How many RTD sensors can the IS200PRTDH1A support simultaneously?

It accommodates up to 16 three-wire RTD inputs, each with independent signal conditioning and isolation.

-

Which RTD standards are compatible with this board?

It supports Pt100 (IEC 751), 120 Ω Nickel, and other industry-standard RTDs commonly used in turbine and generator monitoring.

-

How is channel-to-channel isolation achieved?

Isolation is provided through high-quality differential amplifiers and opto-coupled circuitry rated at 2500 V RMS.

-

What is the typical measurement accuracy?

The board delivers temperature accuracy of approximately ±0.1 °C when used with calibrated RTDs.

-

Does the board provide cold-junction compensation?

Yes, integrated cold-junction circuitry ensures precise readings despite ambient temperature fluctuations.

-

Is the board hot-swappable?

Yes, it can be inserted or removed while the system remains energized, enabling rapid maintenance or replacement.

-

What kind of shielding is required for sensor cabling?

Twisted, shielded three-wire cables are recommended to maintain noise immunity over long cable runs.

-

How does the board handle open or shorted RTD inputs?

Built-in diagnostics detect sensor faults and report them to the Mark VI/VIe controller for quick troubleshooting.

-

What is the maximum cable length supported for each RTD channel?

Up to 100 m of shielded cable can be used per channel without compromising accuracy, provided proper wiring practices are followed.

-

How are temperature measurements communicated to the control system?

Conditioned analog signals are digitized and transmitted via the Mark VI/VIe high-speed proprietary control bus.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...