Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

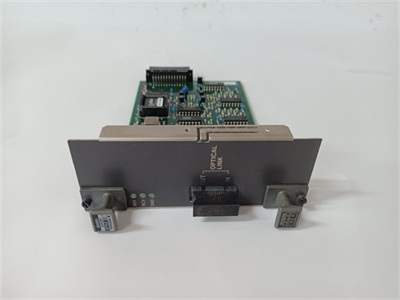

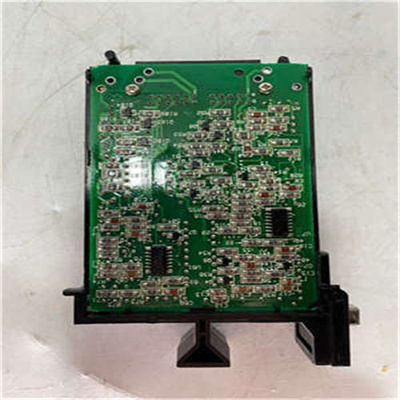

Yokogawa SSC50D-S2121 Duplexed Safety Control Unit

Manufacturer:Yokogawa

Product Number:SSC50D-S2121

Product Type:Duplexed Safety Control Unit

Origin:Japan

Dimensions:482.6 x 266 x 88.1 mm

Weight :8.5 kg

Views:8

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa SSC50D-S2121 Duplexed Safety Control Unit is a high-reliability component designed for use in safety instrumented systems (SIS). It ensures continuous and secure operation by providing duplexed (redundant) control, minimizing the risk of single-point failures. This control unit is primarily implemented in critical industrial processes where system safety and uninterrupted performance are of utmost importance, such as oil & gas, petrochemical, power generation, and chemical plants.

Technical Specifications

| Parameter | Description |

|---|---|

| Model | Yokogawa SSC50D-S2121 Duplexed Safety Control Unit |

| Control Type | Duplexed safety control (redundant configuration) |

| Processor | High-performance dual-redundant CPU |

| Power Supply | 24 VDC (redundant input supported) |

| Dimensions | 482.6 x 266 x 88.1 mm |

| Weight | 8.5 kg |

| Operating Temperature | 0 to 55 °C |

| Storage Temperature | -20 to 70 °C |

| Certifications | SIL3 (IEC 61508 compliant), IEC 61511 ready |

| Diagnostic Functions | Self-checking, error detection, watchdog timer |

| Mounting | Cabinet rack mounting |

| System Redundancy | CPU, power supply, and communication redundancy |

Product Applications

-

Emergency shutdown (ESD) systems in oil refineries

-

Burner management systems in power plants

-

Process safeguarding in petrochemical complexes

-

Safety control in gas processing facilities

-

Chemical reactor overpressure and temperature protection

-

Integrated safety system (ISS) applications in distributed control systems (DCS)

Product Advantages

-

High Reliability: Duplex architecture ensures continuous operation even if one module fails.

-

Safety-Certified: Designed to comply with SIL3, ensuring the highest level of safety integrity.

-

Redundancy at Multiple Levels: CPU, power, and communication redundancy minimize downtime risk.

-

Advanced Diagnostics: Continuous self-checking and fault isolation allow for proactive maintenance.

-

Flexible Integration: Easily integrates with Yokogawa’s ProSafe-RS and other control environments.

-

Scalability: Suitable for both small-scale safety systems and large-scale plant-wide safety integration.

-

Extended Lifecycle Support: Built for long-term plant use with backward compatibility and vendor support.

FAQ

Q1: How does the SSC50D-S2121 handle CPU redundancy?

A1: The unit employs dual CPUs running in parallel. If one fails, the second CPU continues execution seamlessly without disrupting safety functions.

Q2: What safety standard level does the SSC50D-S2121 comply with?

A2: It is certified to SIL3 under IEC 61508, making it suitable for high-integrity safety functions.

Q3: Can the SSC50D-S2121 be integrated with ProSafe-RS?

A3: Yes, it is fully compatible with Yokogawa ProSafe-RS, enabling unified safety and process control management.

Q4: What happens if a power supply unit fails?

A4: The duplex power configuration ensures continuous operation. The system automatically switches to the redundant supply without interruption.

Q5: Does the SSC50D-S2121 support hot swapping of modules?

A5: Yes, critical modules such as power supply and CPU can be hot-swapped to minimize downtime.

Q6: What diagnostic features are available?

A6: The unit provides watchdog timers, error detection, continuous self-checking, and fault isolation to maintain system integrity.

Q7: How is communication redundancy achieved?

A7: It uses dual communication paths, ensuring that even if one network fails, the other maintains safe and reliable data transfer.

Q8: Can it be used in harsh environments?

A8: Yes, with its robust design, it supports operation in industrial temperature ranges and is resistant to vibration and electrical noise.

Q9: How is synchronization maintained between redundant CPUs?

A9: The CPUs constantly exchange state information over a high-speed internal bus, ensuring synchronized execution of safety logic.

Q10: What type of I/O modules can be connected?

A10: The SSC50D-S2121 supports Yokogawa safety I/O modules, including digital input, digital output, and analog input/output units designed for SIS applications.

Yokogawa SSC50D-S2121 Duplexed Safety Control Unit

Manufacturer:Yokogawa

Product Number:SSC50D-S2121

Product Type:Duplexed Safety Control Unit

Origin:Japan

Dimensions:482.6 x 266 x 88.1 mm

Weight :8.5 kg

Views:8

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa SSC50D-S2121 Duplexed Safety Control Unit is a high-reliability component designed for use in safety instrumented systems (SIS). It ensures continuous and secure operation by providing duplexed (redundant) control, minimizing the risk of single-point failures. This control unit is primarily implemented in critical industrial processes where system safety and uninterrupted performance are of utmost importance, such as oil & gas, petrochemical, power generation, and chemical plants.

Technical Specifications

| Parameter | Description |

|---|---|

| Model | Yokogawa SSC50D-S2121 Duplexed Safety Control Unit |

| Control Type | Duplexed safety control (redundant configuration) |

| Processor | High-performance dual-redundant CPU |

| Power Supply | 24 VDC (redundant input supported) |

| Dimensions | 482.6 x 266 x 88.1 mm |

| Weight | 8.5 kg |

| Operating Temperature | 0 to 55 °C |

| Storage Temperature | -20 to 70 °C |

| Certifications | SIL3 (IEC 61508 compliant), IEC 61511 ready |

| Diagnostic Functions | Self-checking, error detection, watchdog timer |

| Mounting | Cabinet rack mounting |

| System Redundancy | CPU, power supply, and communication redundancy |

Product Applications

-

Emergency shutdown (ESD) systems in oil refineries

-

Burner management systems in power plants

-

Process safeguarding in petrochemical complexes

-

Safety control in gas processing facilities

-

Chemical reactor overpressure and temperature protection

-

Integrated safety system (ISS) applications in distributed control systems (DCS)

Product Advantages

-

High Reliability: Duplex architecture ensures continuous operation even if one module fails.

-

Safety-Certified: Designed to comply with SIL3, ensuring the highest level of safety integrity.

-

Redundancy at Multiple Levels: CPU, power, and communication redundancy minimize downtime risk.

-

Advanced Diagnostics: Continuous self-checking and fault isolation allow for proactive maintenance.

-

Flexible Integration: Easily integrates with Yokogawa’s ProSafe-RS and other control environments.

-

Scalability: Suitable for both small-scale safety systems and large-scale plant-wide safety integration.

-

Extended Lifecycle Support: Built for long-term plant use with backward compatibility and vendor support.

FAQ

Q1: How does the SSC50D-S2121 handle CPU redundancy?

A1: The unit employs dual CPUs running in parallel. If one fails, the second CPU continues execution seamlessly without disrupting safety functions.

Q2: What safety standard level does the SSC50D-S2121 comply with?

A2: It is certified to SIL3 under IEC 61508, making it suitable for high-integrity safety functions.

Q3: Can the SSC50D-S2121 be integrated with ProSafe-RS?

A3: Yes, it is fully compatible with Yokogawa ProSafe-RS, enabling unified safety and process control management.

Q4: What happens if a power supply unit fails?

A4: The duplex power configuration ensures continuous operation. The system automatically switches to the redundant supply without interruption.

Q5: Does the SSC50D-S2121 support hot swapping of modules?

A5: Yes, critical modules such as power supply and CPU can be hot-swapped to minimize downtime.

Q6: What diagnostic features are available?

A6: The unit provides watchdog timers, error detection, continuous self-checking, and fault isolation to maintain system integrity.

Q7: How is communication redundancy achieved?

A7: It uses dual communication paths, ensuring that even if one network fails, the other maintains safe and reliable data transfer.

Q8: Can it be used in harsh environments?

A8: Yes, with its robust design, it supports operation in industrial temperature ranges and is resistant to vibration and electrical noise.

Q9: How is synchronization maintained between redundant CPUs?

A9: The CPUs constantly exchange state information over a high-speed internal bus, ensuring synchronized execution of safety logic.

Q10: What type of I/O modules can be connected?

A10: The SSC50D-S2121 supports Yokogawa safety I/O modules, including digital input, digital output, and analog input/output units designed for SIS applications.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...