Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

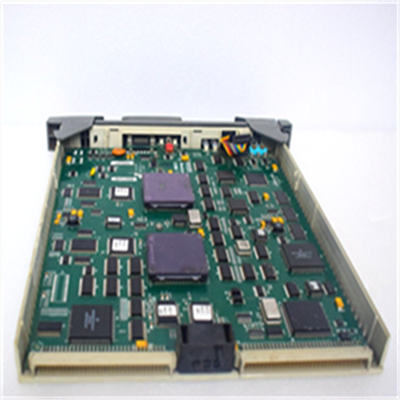

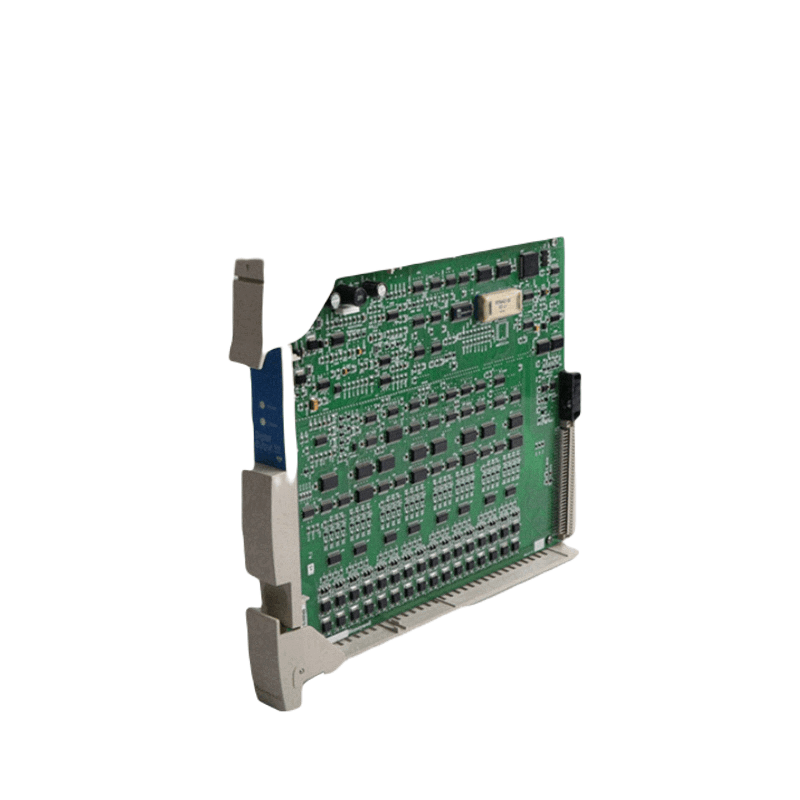

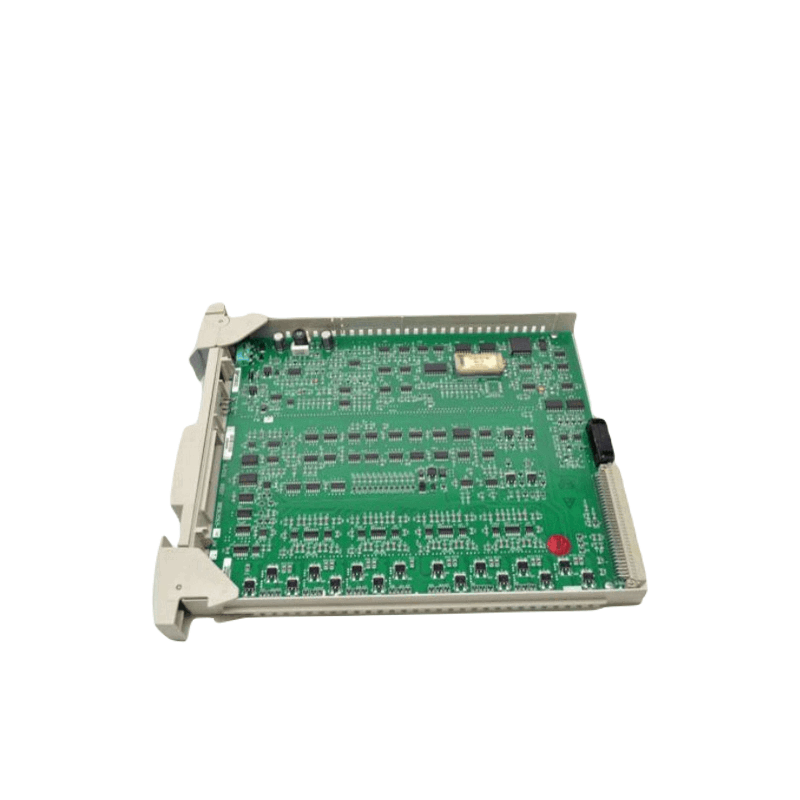

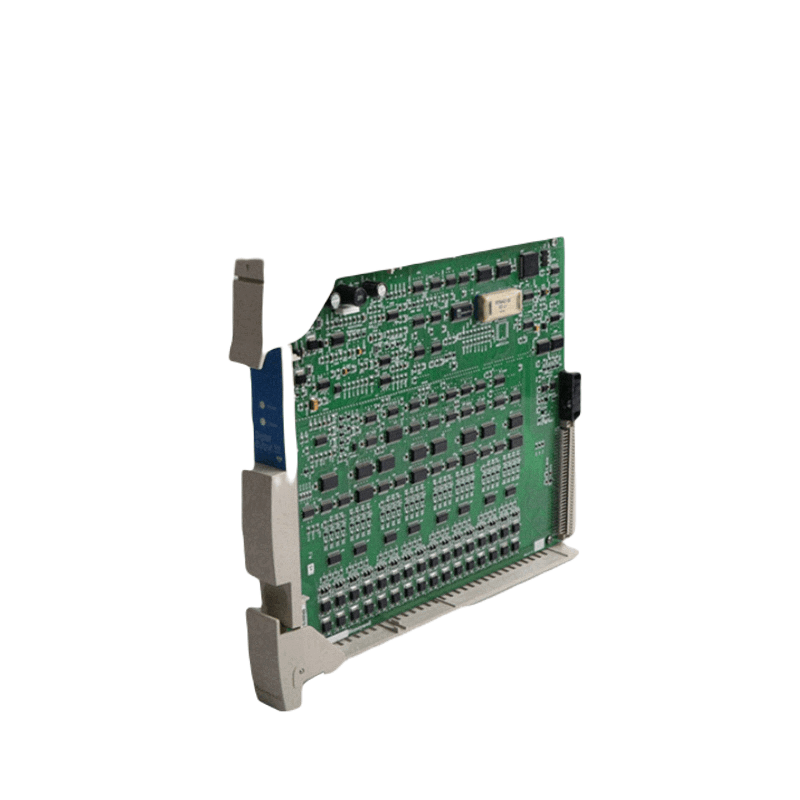

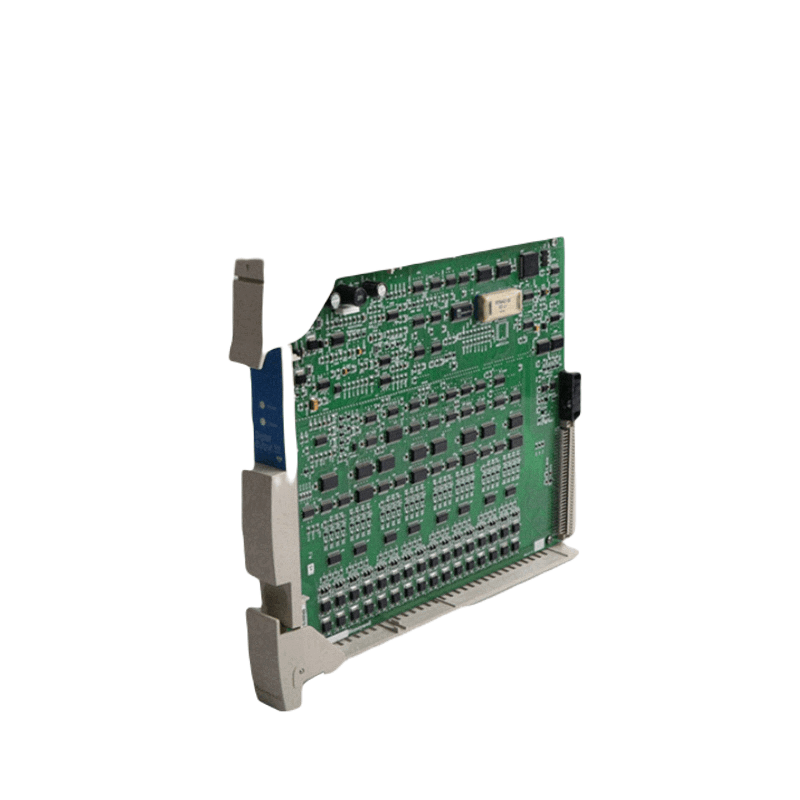

Honeywell FC-SAI-1620M Safety Manager System Module

Manufacturer : Honeywell

Product No. : FC-SAI-1620M

Product Type : Safety Manager System Module

Shipping weight : 3 Kg

Availability: In Stock

Factory Warranty: 12 Months

Payment:T/T

PRICE:$123

PRODUCT ORIGIN: USA

SHIPPING PORT:Xiamen

Product Description

The Honeywell Safety Manager™ stands as a dependable and high-integrity safety system tailored for critical control applications. It forms an integral part of Honeywell’s Experion™ PKS, seamlessly integrated into PlantScape, or can operate autonomously. Safety Manager serves as the foundation for functional safety, ensuring the well-being of individuals, plant assets, and the environment, while optimizing plant continuity.

Safety Manager is a user-programmable, modular, microprocessor-based safety system capable of performing a broad spectrum of high-integrity process control and safety instrumented functions, including:

- High-integrity process control

- Burner/boiler management systems

- Process safeguarding and emergency shutdown

- Turbine and compressor safeguarding

- Fire and gas detection systems

- Pipeline monitoring

Enhancing Business Outcomes

Safety Manager™ is the evolution of the well-established Fail Safe Controller (FSC®) safety system platform that has garnered global recognition for over 15 years. It embodies proven technology backed by Honeywell’s two decades of expertise in process safety management. This includes the integration of process safety data, applications, system diagnostics, and critical control strategies.

Designed to elevate business performance, Safety Manager improves process safety and safeguards plant assets and personnel. Seamlessly integrated with Experion™ Process Knowledge System (PKS), safety systems converge into a single architecture, offering an exceptional opportunity to enhance both safety and process availability. Experion PKS ensures unparalleled connectivity across process and business operations, optimizing workflows, streamlining maintenance tasks, enhancing safety management, and liberating personnel from manual tasks.

Built on QMR Technology

Safety Manager™ rests upon the reliable Quadruple Modular Redundant (QMR™) diagnostic-based technology with a 2oo4D architecture. QMR enhances system flexibility, augments diagnostic messaging capabilities, and bolsters system fault tolerance for critical applications. This technology empowers Safety Manager to handle multiple system faults, aligning with the demands of critical control applications.

Furthermore, Safety Manager serves as the cornerstone for integrating SIL (safety integrity level) rated sensors and valve actuators in the field. This ensures the effective deployment of safety instrumented functions for intricate and hazardous processes. Whether integrating SIL1-2 safety transmitters (ST3000 and STT250) or safety valve positioners for enhanced safety and field asset management, Safety Manager is the optimal enabler for your Safety Instrumented Systems (SIS).

Benefits

- Streamlined engineering and design efficiency – simplifying safety network design

- Enhanced system reliability and robustness – employing Design for Six Sigma (DFSS) and IEC 61508 criteria

- Augmented process availability – leveraging QMR technology for uninterrupted operation during system degradation

- Improved operation and maintenance performance – unifying critical process data and control information for seamless access

- Safeguarding investments – facilitating migration from FSC to QMR safety technology

- Adherence to safety standards – equipped with SIL3 safety compliance tools, hardware, and software for various industries throughout an installation’s lifecycle

Compliance to Safety Standards

A crucial requirement for IEC 61508 compliance is the availability of an application change history. Safety Manager™ addresses this with the Safety Audit Tracker, offering an automatically enabled audit trail that monitors all changes made to an application. This eliminates the need for cumbersome procedures or extensive loggings. Safety Manager complies with international standards such as NFPA 85, 86, VDE 0116 (for BMS), IEC 61508, ISA S84.01, DIN V 19250, UL, FM, ATEX (for ESD), and EN54-2, NFPA 72, Lloyd’s Register (for F&G).

In a nutshell, Honeywell’s Safety Manager, with its comprehensive set of SIL3 safety compliance tools, hardware, and software, furnishes excellent protection for safety applications across diverse industries throughout an installation’s lifetime. Coupled with Experion or other process control systems, Safety Manager establishes the bedrock for critical control and safety integration, mitigating risks, reducing costs, and enhancing plant safety.

Engineering Environment

The Safety Builder brings about efficiency in engineering and design. The Network Configurator, a novel addition, facilitates easy design of safety networks through intuitive drag & drop functionality. Complex configurations are simplified, saving valuable engineering and testing time. The Functional Logic Diagram (FLD) Editor, a proven tool, enables swift application design while adhering to IEC 61131 standards.

Safety Manager R120 introduces several enhancements to aid project engineers, including features like copying applications across plants, bulk copying of points, renaming points, and more. It enables multi-user access to the Safety Manager database and controller, supporting distributed logic development.

Process Availability

By leveraging the proven QMR technology, Safety Manager™ ensures unlimited run time for single channel operation, leading to enhanced process availability. Online system modification procedures have been streamlined, allowing improved application and system upgrades during plant start-ups or throughout process operation. This is estimated to improve process uptime by up to 20%.

Operation and Maintenance Performance

Safety Manager™ brings together critical process data and control information, granting single-window access for operation and maintenance. Through TÜV SIL3 approved Universal Safety Interfaces (USI) connected to the Experion Fault Tolerant Ethernet (FTE) network, multiple Safety Managers merge into a unified safety system architecture. Extensive Ethernet usage facilitates fast, secure, and reliable data exchange with Experion, boosting operator and maintenance efficiency. Additionally, Safety Manager’s robust self-testing and diagnostic capability extends the system’s proof test interval, reducing operational and maintenance costs.

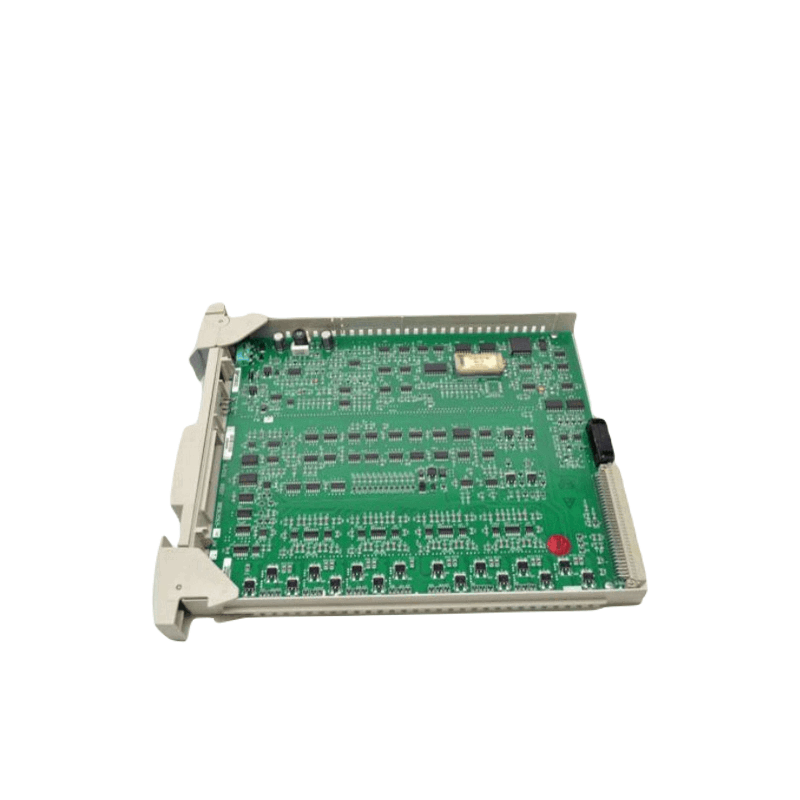

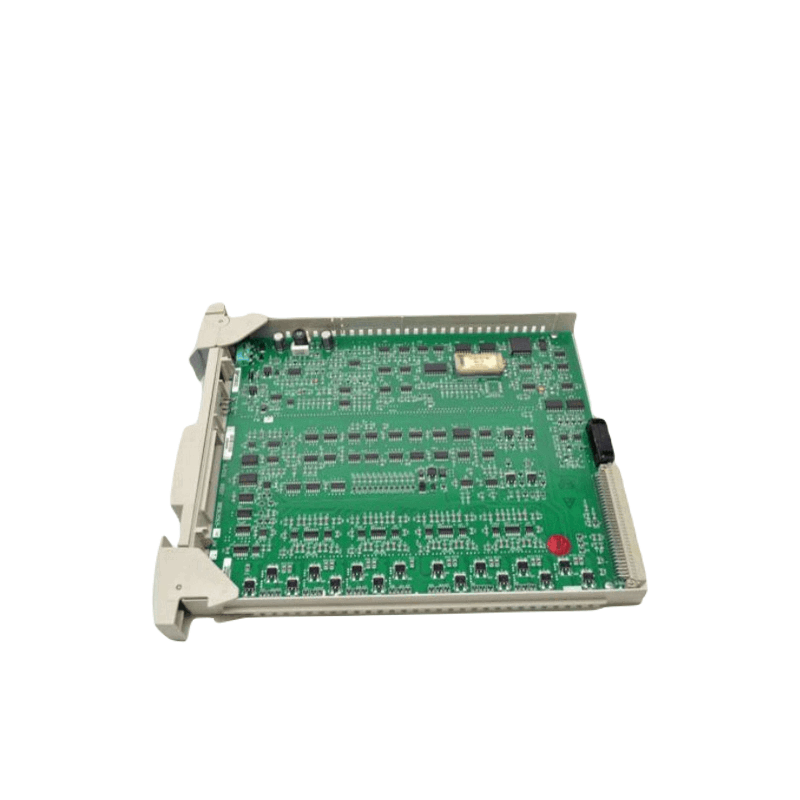

Honeywell FC-SAI-1620M Safety Manager System Module

Manufacturer : Honeywell

Product No. : FC-SAI-1620M

Product Type : Safety Manager System Module

Shipping weight : 3 Kg

Availability: In Stock

Factory Warranty: 12 Months

Payment:T/T

PRICE:$123

PRODUCT ORIGIN: USA

SHIPPING PORT:Xiamen

Product Description

The Honeywell Safety Manager™ stands as a dependable and high-integrity safety system tailored for critical control applications. It forms an integral part of Honeywell’s Experion™ PKS, seamlessly integrated into PlantScape, or can operate autonomously. Safety Manager serves as the foundation for functional safety, ensuring the well-being of individuals, plant assets, and the environment, while optimizing plant continuity.

Safety Manager is a user-programmable, modular, microprocessor-based safety system capable of performing a broad spectrum of high-integrity process control and safety instrumented functions, including:

- High-integrity process control

- Burner/boiler management systems

- Process safeguarding and emergency shutdown

- Turbine and compressor safeguarding

- Fire and gas detection systems

- Pipeline monitoring

Enhancing Business Outcomes

Safety Manager™ is the evolution of the well-established Fail Safe Controller (FSC®) safety system platform that has garnered global recognition for over 15 years. It embodies proven technology backed by Honeywell’s two decades of expertise in process safety management. This includes the integration of process safety data, applications, system diagnostics, and critical control strategies.

Designed to elevate business performance, Safety Manager improves process safety and safeguards plant assets and personnel. Seamlessly integrated with Experion™ Process Knowledge System (PKS), safety systems converge into a single architecture, offering an exceptional opportunity to enhance both safety and process availability. Experion PKS ensures unparalleled connectivity across process and business operations, optimizing workflows, streamlining maintenance tasks, enhancing safety management, and liberating personnel from manual tasks.

Built on QMR Technology

Safety Manager™ rests upon the reliable Quadruple Modular Redundant (QMR™) diagnostic-based technology with a 2oo4D architecture. QMR enhances system flexibility, augments diagnostic messaging capabilities, and bolsters system fault tolerance for critical applications. This technology empowers Safety Manager to handle multiple system faults, aligning with the demands of critical control applications.

Furthermore, Safety Manager serves as the cornerstone for integrating SIL (safety integrity level) rated sensors and valve actuators in the field. This ensures the effective deployment of safety instrumented functions for intricate and hazardous processes. Whether integrating SIL1-2 safety transmitters (ST3000 and STT250) or safety valve positioners for enhanced safety and field asset management, Safety Manager is the optimal enabler for your Safety Instrumented Systems (SIS).

Benefits

- Streamlined engineering and design efficiency – simplifying safety network design

- Enhanced system reliability and robustness – employing Design for Six Sigma (DFSS) and IEC 61508 criteria

- Augmented process availability – leveraging QMR technology for uninterrupted operation during system degradation

- Improved operation and maintenance performance – unifying critical process data and control information for seamless access

- Safeguarding investments – facilitating migration from FSC to QMR safety technology

- Adherence to safety standards – equipped with SIL3 safety compliance tools, hardware, and software for various industries throughout an installation’s lifecycle

Compliance to Safety Standards

A crucial requirement for IEC 61508 compliance is the availability of an application change history. Safety Manager™ addresses this with the Safety Audit Tracker, offering an automatically enabled audit trail that monitors all changes made to an application. This eliminates the need for cumbersome procedures or extensive loggings. Safety Manager complies with international standards such as NFPA 85, 86, VDE 0116 (for BMS), IEC 61508, ISA S84.01, DIN V 19250, UL, FM, ATEX (for ESD), and EN54-2, NFPA 72, Lloyd’s Register (for F&G).

In a nutshell, Honeywell’s Safety Manager, with its comprehensive set of SIL3 safety compliance tools, hardware, and software, furnishes excellent protection for safety applications across diverse industries throughout an installation’s lifetime. Coupled with Experion or other process control systems, Safety Manager establishes the bedrock for critical control and safety integration, mitigating risks, reducing costs, and enhancing plant safety.

Engineering Environment

The Safety Builder brings about efficiency in engineering and design. The Network Configurator, a novel addition, facilitates easy design of safety networks through intuitive drag & drop functionality. Complex configurations are simplified, saving valuable engineering and testing time. The Functional Logic Diagram (FLD) Editor, a proven tool, enables swift application design while adhering to IEC 61131 standards.

Safety Manager R120 introduces several enhancements to aid project engineers, including features like copying applications across plants, bulk copying of points, renaming points, and more. It enables multi-user access to the Safety Manager database and controller, supporting distributed logic development.

Process Availability

By leveraging the proven QMR technology, Safety Manager™ ensures unlimited run time for single channel operation, leading to enhanced process availability. Online system modification procedures have been streamlined, allowing improved application and system upgrades during plant start-ups or throughout process operation. This is estimated to improve process uptime by up to 20%.

Operation and Maintenance Performance

Safety Manager™ brings together critical process data and control information, granting single-window access for operation and maintenance. Through TÜV SIL3 approved Universal Safety Interfaces (USI) connected to the Experion Fault Tolerant Ethernet (FTE) network, multiple Safety Managers merge into a unified safety system architecture. Extensive Ethernet usage facilitates fast, secure, and reliable data exchange with Experion, boosting operator and maintenance efficiency. Additionally, Safety Manager’s robust self-testing and diagnostic capability extends the system’s proof test interval, reducing operational and maintenance costs.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...