Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

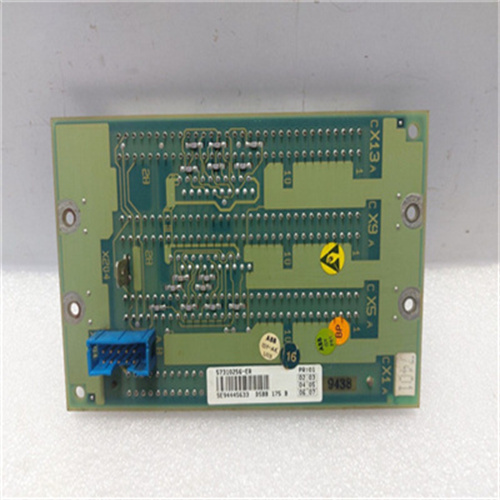

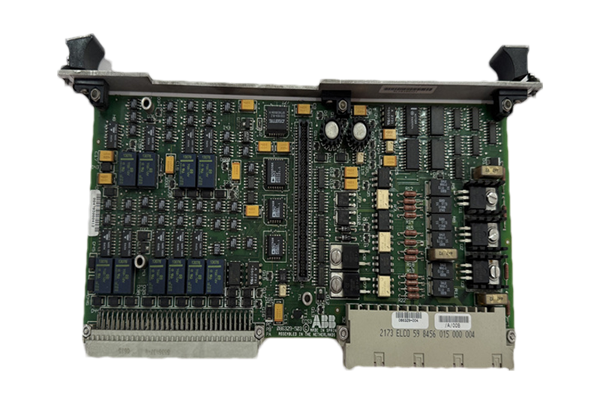

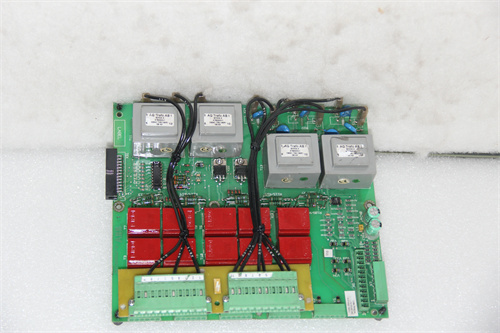

ABB DSQC 236G YB560103-CD Servo Axis Drive Unit

Manufacturer:ABB

Product Number:DSQC 236G YB560103-CD

Product Type:Servo Axis Drive Unit

Origin:Sweden (SE)

Dimensions:254 × 25 × 245 mm

Weight:1.36 kg

Views:61

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB DSQC 236G YB560103-CD is a servo axis drive unit used in ABB industrial robot systems, particularly within the IRB 6400 series with S4 control systems. It manages precise motor control, ensuring accurate and stable axis movement during robotic operations. It is integral to closed-loop motion systems.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Type | Servo Axis Drive Unit |

| Model | DSQC 236G |

| Part Number | YB560103-CD |

| System Compatibility | ABB IRB6400 with S4 Controller |

| Voltage Range | 475V AC, 3-phase, 50–60 Hz |

| Mounting Type | Rack-mounted in control cabinet |

| Control Type | Closed-loop with resolver input |

| Dimensions (W×H×D) | 254 × 25 × 245 mm |

| Weight | 1.36 kg |

| Safety Integration | Works with dual-channel Run Chains (KM1/KM2) |

| Cooling Method | Passive with enclosure ventilation |

Applications

-

ABB IRB6400 industrial robot series

-

Motion control for servo-driven robot joints

-

High-precision multi-axis automation

-

Automotive assembly and welding

-

General industrial manufacturing robotics

Advantages

-

High compatibility with ABB S4 systems

-

Reliable axis control for precise motion

-

Compact design for efficient panel space usage

-

Integrates with ABB’s comprehensive safety chain

-

Built-in diagnostics via system LEDs

-

Easy maintenance and replacement procedures

FAQ (Frequently Asked Questions)

Q1: What system is the DSQC 236G compatible with?

A1: It is specifically designed for ABB IRB6400 robots with the S4 controller system.

Q2: Can I use DSQC 236G with newer robot models?

A2: No, it is primarily intended for legacy systems like the IRB6400. Compatibility with newer models is not guaranteed.

Q3: Is the DSQC 236G hot-swappable?

A3: No. Always power down and discharge the system before replacing the unit to avoid damage or injury.

Q4: What type of motors does it control?

A4: It controls ABB servo motors that operate using resolver feedback and PWM drives.

Q5: Does it support diagnostics?

A5: Yes, it uses onboard LED indicators for status and fault conditions.

Q6: What is the importance of resolver feedback?

A6: Resolver feedback allows for accurate, real-time positioning data, essential for precision control.

Q7: Is the DSQC 236G still in production?

A7: Contact Us.

Q8: Can multiple DSQC 236G units be installed in a system?

A8: Yes, typically one unit per robot axis is used in the control system.

Q9: What are the safety considerations when replacing the unit?

A9: Ensure full system lockout/tagout, and use ESD protection to prevent component damage.

Q10: How do I identify a faulty DSQC 236G?

A10: Check for fault LEDs, irregular axis behavior, or fault logs in the teach pendant system.

ABB DSQC 236G YB560103-CD Servo Axis Drive Unit

Manufacturer:ABB

Product Number:DSQC 236G YB560103-CD

Product Type:Servo Axis Drive Unit

Origin:Sweden (SE)

Dimensions:254 × 25 × 245 mm

Weight:1.36 kg

Views:61

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB DSQC 236G YB560103-CD is a servo axis drive unit used in ABB industrial robot systems, particularly within the IRB 6400 series with S4 control systems. It manages precise motor control, ensuring accurate and stable axis movement during robotic operations. It is integral to closed-loop motion systems.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Type | Servo Axis Drive Unit |

| Model | DSQC 236G |

| Part Number | YB560103-CD |

| System Compatibility | ABB IRB6400 with S4 Controller |

| Voltage Range | 475V AC, 3-phase, 50–60 Hz |

| Mounting Type | Rack-mounted in control cabinet |

| Control Type | Closed-loop with resolver input |

| Dimensions (W×H×D) | 254 × 25 × 245 mm |

| Weight | 1.36 kg |

| Safety Integration | Works with dual-channel Run Chains (KM1/KM2) |

| Cooling Method | Passive with enclosure ventilation |

Applications

-

ABB IRB6400 industrial robot series

-

Motion control for servo-driven robot joints

-

High-precision multi-axis automation

-

Automotive assembly and welding

-

General industrial manufacturing robotics

Advantages

-

High compatibility with ABB S4 systems

-

Reliable axis control for precise motion

-

Compact design for efficient panel space usage

-

Integrates with ABB’s comprehensive safety chain

-

Built-in diagnostics via system LEDs

-

Easy maintenance and replacement procedures

FAQ (Frequently Asked Questions)

Q1: What system is the DSQC 236G compatible with?

A1: It is specifically designed for ABB IRB6400 robots with the S4 controller system.

Q2: Can I use DSQC 236G with newer robot models?

A2: No, it is primarily intended for legacy systems like the IRB6400. Compatibility with newer models is not guaranteed.

Q3: Is the DSQC 236G hot-swappable?

A3: No. Always power down and discharge the system before replacing the unit to avoid damage or injury.

Q4: What type of motors does it control?

A4: It controls ABB servo motors that operate using resolver feedback and PWM drives.

Q5: Does it support diagnostics?

A5: Yes, it uses onboard LED indicators for status and fault conditions.

Q6: What is the importance of resolver feedback?

A6: Resolver feedback allows for accurate, real-time positioning data, essential for precision control.

Q7: Is the DSQC 236G still in production?

A7: Contact Us.

Q8: Can multiple DSQC 236G units be installed in a system?

A8: Yes, typically one unit per robot axis is used in the control system.

Q9: What are the safety considerations when replacing the unit?

A9: Ensure full system lockout/tagout, and use ESD protection to prevent component damage.

Q10: How do I identify a faulty DSQC 236G?

A10: Check for fault LEDs, irregular axis behavior, or fault logs in the teach pendant system.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...