Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

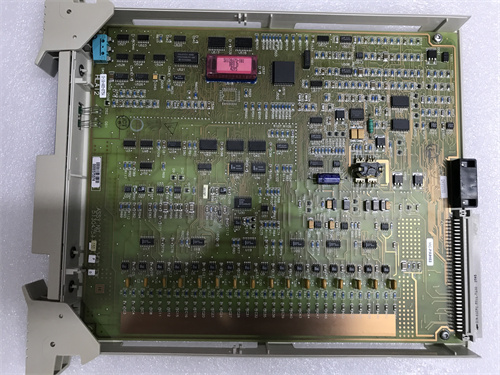

Honeywell 900C70-0460 HC900 C70 Controller CPU

Manufacturer:Honeywell

Product Number:900C70-0460

Product Type:HC900 C70 Controller CPU

Origin:USA

Dimensions:137 × 38.1 × 137.16 mm

Weight:0.4 kg

Views:82

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell 900C70-0460 is the top-tier controller CPU in the HC900 Hybrid Control System family, offering advanced processing power and redundancy capabilities. The C70 CPU is designed for complex process automation systems that require large I/O handling, rapid execution cycles, and uncompromising reliability in hybrid industrial environments.

As a high-performance controller, the 900C70-0460 supports large-scale control applications across industries such as chemicals, pharmaceuticals, power generation, and thermal processing. With built-in features like peer-to-peer networking, web server functionality, and support for safety systems, the C70 CPU provides unmatched versatility and dependability.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | 900C70-0460 |

| Series | HC900 Hybrid Controller Series |

| CPU Type | C70 Central Processing Unit |

| Processor Type | High-speed 32-bit RISC Processor |

| Execution Speed | Sub-5ms scan time for 1000 blocks |

| Memory | 20MB Flash, 8MB RAM |

| Max I/O Capacity | Up to 4000+ I/O points |

| Rack Support | Supports up to 8 local/remote I/O racks |

| Redundancy Support | Yes – CPU, power, and communication |

| Ethernet Ports | 2 × 10/100 Mbps (Modbus TCP/IP, peer-to-peer, OPC) |

| Serial Ports | 1 × RS485/RS232 (Modbus RTU) |

| Supported Protocols | Modbus RTU, Modbus TCP/IP, peer messaging, OPC DA |

| Programming Software | Control Designer (Function Block Diagram Programming) |

| Web Server | Built-in for remote monitoring and diagnostics |

| Time Synchronization | SNTP/NTP support |

| Real-Time Clock | Yes |

| Operating Temperature | 0 to 60°C (32 to 140°F) |

| Storage Temperature | -40 to 85°C (-40 to 185°F) |

| Humidity Range | 5% to 95% RH (non-condensing) |

| Power Supply Requirement | 24 VDC nominal (10.2–30 VDC range) |

| Mounting Type | DIN rail or panel mount |

| Dimensions (W × H × D) | 137 × 38.1 × 137.16 mm |

| Weight | 0.4 kg |

| Certifications | CE, UL, CSA, RoHS, SIL2-capable |

Product Applications

The 900C70-0460 C70 Controller is engineered for mission-critical and high-throughput automation applications. Its advanced capabilities allow for:

-

Batch Processing in chemical and pharmaceutical plants requiring recipe control and data integrity.

-

Combustion and Furnace Control in thermal processes demanding precise temperature and safety loops.

-

Power Generation and Boiler Control, including burner management systems.

-

Water/Wastewater Automation involving pump control, filtration systems, and energy optimization.

-

Food & Beverage Industry control systems for large-scale production lines.

-

Safety-Critical Systems, integrating ESD (Emergency Shutdown), BMS (Burner Management System), and SIS (Safety Instrumented Systems).

Product Advantages

-

Highest Performance in HC900 Family: Capable of handling over 4000 I/O points with high-speed execution and deterministic performance.

-

Robust Redundancy Options: Supports full redundancy for CPU, communication, and power modules, ensuring zero downtime in critical applications.

-

Hybrid Control: Simultaneously manages discrete logic, analog processing, and PID control in a unified environment.

-

Advanced Communication: Multiple protocols including OPC DA, Modbus RTU/TCP, and peer-to-peer over Ethernet.

-

Remote Access & Web Monitoring: Embedded web server enables diagnostics and process supervision from any browser.

-

Security & Time-Sync: Built-in SNTP/NTP time synchronization and secure password-controlled access.

-

Field-Proven Stability: Industrial-grade design with high tolerance to environmental conditions.

-

Versatile Programming: Control Designer software supports modular and scalable design using function blocks.

-

Long-Term Lifecycle Support: Backed by Honeywell’s commitment to industrial-grade longevity and global service.

-

Modular Integration: Easily integrates with SCADA, HMI, and third-party systems through open interfaces.

Frequently Asked Questions (FAQ)

-

What distinguishes the C70 CPU from C30 and C50 models?

The C70 offers the highest processing power, the largest I/O capacity (4000+ points), and advanced redundancy features compared to the C30 and C50.

-

Can the 900C70-0460 be used in safety-related applications?

Yes, it is SIL2 capable and suitable for SIS, ESD, and BMS systems.

-

Does the controller support redundant CPU configurations?

Absolutely. It supports redundant CPU, power, and Ethernet configurations for fault tolerance.

-

What software is used to program the C70 controller?

Honeywell’s Control Designer software using function block programming.

-

Is the controller compatible with Modbus devices?

Yes, it supports both Modbus TCP/IP and Modbus RTU.

-

What kind of I/O modules are compatible with the C70 CPU?

It supports all HC900 analog, digital, and specialty I/O modules via backplane and remote I/O racks.

-

Can the controller be integrated with third-party SCADA?

Yes, using OPC DA and standard Modbus protocols, integration is seamless.

-

Does the C70 have real-time clock support?

Yes, it includes a built-in real-time clock with NTP/SNTP time synchronization.

-

Is there built-in diagnostic functionality?

Yes, both local and remote diagnostics are supported through the web interface and software tools.

-

What is the power requirement for this CPU?

The controller operates at 24 VDC within a range of 10.2–30 VDC.

Honeywell 900C70-0460 HC900 C70 Controller CPU

Manufacturer:Honeywell

Product Number:900C70-0460

Product Type:HC900 C70 Controller CPU

Origin:USA

Dimensions:137 × 38.1 × 137.16 mm

Weight:0.4 kg

Views:82

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell 900C70-0460 is the top-tier controller CPU in the HC900 Hybrid Control System family, offering advanced processing power and redundancy capabilities. The C70 CPU is designed for complex process automation systems that require large I/O handling, rapid execution cycles, and uncompromising reliability in hybrid industrial environments.

As a high-performance controller, the 900C70-0460 supports large-scale control applications across industries such as chemicals, pharmaceuticals, power generation, and thermal processing. With built-in features like peer-to-peer networking, web server functionality, and support for safety systems, the C70 CPU provides unmatched versatility and dependability.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | 900C70-0460 |

| Series | HC900 Hybrid Controller Series |

| CPU Type | C70 Central Processing Unit |

| Processor Type | High-speed 32-bit RISC Processor |

| Execution Speed | Sub-5ms scan time for 1000 blocks |

| Memory | 20MB Flash, 8MB RAM |

| Max I/O Capacity | Up to 4000+ I/O points |

| Rack Support | Supports up to 8 local/remote I/O racks |

| Redundancy Support | Yes – CPU, power, and communication |

| Ethernet Ports | 2 × 10/100 Mbps (Modbus TCP/IP, peer-to-peer, OPC) |

| Serial Ports | 1 × RS485/RS232 (Modbus RTU) |

| Supported Protocols | Modbus RTU, Modbus TCP/IP, peer messaging, OPC DA |

| Programming Software | Control Designer (Function Block Diagram Programming) |

| Web Server | Built-in for remote monitoring and diagnostics |

| Time Synchronization | SNTP/NTP support |

| Real-Time Clock | Yes |

| Operating Temperature | 0 to 60°C (32 to 140°F) |

| Storage Temperature | -40 to 85°C (-40 to 185°F) |

| Humidity Range | 5% to 95% RH (non-condensing) |

| Power Supply Requirement | 24 VDC nominal (10.2–30 VDC range) |

| Mounting Type | DIN rail or panel mount |

| Dimensions (W × H × D) | 137 × 38.1 × 137.16 mm |

| Weight | 0.4 kg |

| Certifications | CE, UL, CSA, RoHS, SIL2-capable |

Product Applications

The 900C70-0460 C70 Controller is engineered for mission-critical and high-throughput automation applications. Its advanced capabilities allow for:

-

Batch Processing in chemical and pharmaceutical plants requiring recipe control and data integrity.

-

Combustion and Furnace Control in thermal processes demanding precise temperature and safety loops.

-

Power Generation and Boiler Control, including burner management systems.

-

Water/Wastewater Automation involving pump control, filtration systems, and energy optimization.

-

Food & Beverage Industry control systems for large-scale production lines.

-

Safety-Critical Systems, integrating ESD (Emergency Shutdown), BMS (Burner Management System), and SIS (Safety Instrumented Systems).

Product Advantages

-

Highest Performance in HC900 Family: Capable of handling over 4000 I/O points with high-speed execution and deterministic performance.

-

Robust Redundancy Options: Supports full redundancy for CPU, communication, and power modules, ensuring zero downtime in critical applications.

-

Hybrid Control: Simultaneously manages discrete logic, analog processing, and PID control in a unified environment.

-

Advanced Communication: Multiple protocols including OPC DA, Modbus RTU/TCP, and peer-to-peer over Ethernet.

-

Remote Access & Web Monitoring: Embedded web server enables diagnostics and process supervision from any browser.

-

Security & Time-Sync: Built-in SNTP/NTP time synchronization and secure password-controlled access.

-

Field-Proven Stability: Industrial-grade design with high tolerance to environmental conditions.

-

Versatile Programming: Control Designer software supports modular and scalable design using function blocks.

-

Long-Term Lifecycle Support: Backed by Honeywell’s commitment to industrial-grade longevity and global service.

-

Modular Integration: Easily integrates with SCADA, HMI, and third-party systems through open interfaces.

Frequently Asked Questions (FAQ)

-

What distinguishes the C70 CPU from C30 and C50 models?

The C70 offers the highest processing power, the largest I/O capacity (4000+ points), and advanced redundancy features compared to the C30 and C50.

-

Can the 900C70-0460 be used in safety-related applications?

Yes, it is SIL2 capable and suitable for SIS, ESD, and BMS systems.

-

Does the controller support redundant CPU configurations?

Absolutely. It supports redundant CPU, power, and Ethernet configurations for fault tolerance.

-

What software is used to program the C70 controller?

Honeywell’s Control Designer software using function block programming.

-

Is the controller compatible with Modbus devices?

Yes, it supports both Modbus TCP/IP and Modbus RTU.

-

What kind of I/O modules are compatible with the C70 CPU?

It supports all HC900 analog, digital, and specialty I/O modules via backplane and remote I/O racks.

-

Can the controller be integrated with third-party SCADA?

Yes, using OPC DA and standard Modbus protocols, integration is seamless.

-

Does the C70 have real-time clock support?

Yes, it includes a built-in real-time clock with NTP/SNTP time synchronization.

-

Is there built-in diagnostic functionality?

Yes, both local and remote diagnostics are supported through the web interface and software tools.

-

What is the power requirement for this CPU?

The controller operates at 24 VDC within a range of 10.2–30 VDC.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...