Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

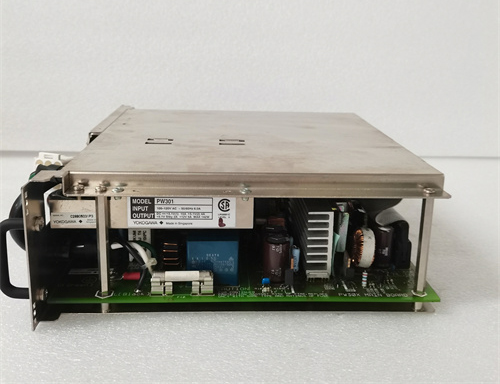

Yokogawa A2SDV105-S000 Digital Input Adapter Module

Manufacturer:Yokogawa

Product Number:A2SDV105-S000

Product Type:Digital Input Adapter Module

Origin:Japan

Dimensions:130 x 12.8 x 40 mm

Weight :0.1 kg

Views:50

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa A2SDV105-S000 is a precision digital valve positioner designed for seamless integration in industrial process control systems. Engineered to enhance control performance and reliability, this valve positioner ensures precise actuator positioning, enabling optimized flow control in a wide range of industrial applications. Its robust design allows for use in harsh environments, maintaining performance under varying temperatures, vibrations, and humidity conditions. The device incorporates advanced diagnostics, providing real-time feedback and ensuring predictive maintenance for process systems.

Product Advantages

-

High Precision Control: Offers accurate positioning for valves, improving process stability and efficiency.

-

Robust Construction: Built to withstand harsh environments, resistant to vibration, temperature extremes, and moisture.

-

Advanced Diagnostics: Provides real-time data and alerts for predictive maintenance, minimizing downtime.

-

Easy Integration: Compatible with a wide range of control systems, supporting HART communication for digital process automation.

-

Energy Efficient: Optimized pneumatic and electronic systems reduce energy consumption.

-

User-Friendly Calibration: Simplifies setup and maintenance through an intuitive interface and clear visual indicators.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | A2SDV105-S000 |

| Type | Digital Valve Positioner |

| Supply Voltage | 24 V DC |

| Communication Protocol | HART |

| Air Supply Pressure | 0.14–0.7 MPa |

| Operating Temperature | -40°C to 85°C |

| Humidity | 0–95% RH, non-condensing |

| Input Signal | 4–20 mA |

| Output Stroke | 0–20 mA or 0–100% |

| Accuracy | ±0.5% of span |

| Repeatability | ±0.2% of span |

| Materials | Aluminum body, stainless steel internals |

| Weight | 0.1 kg |

| Dimensions (L×W×H) | 130 x 12.8 x 40 mm |

Product Applications

-

Petrochemical Industry: Precise flow and pressure control for reactors, distillation columns, and pipelines.

-

Power Plants: Steam and water control in turbines and boilers, ensuring efficient energy conversion.

-

Water Treatment: Accurate chemical dosing and valve control for clean water and wastewater systems.

-

Pharmaceutical Manufacturing: Control of fluid handling systems for consistent production quality.

-

Food & Beverage: Hygienic flow control solutions for liquid processing and packaging lines.

-

General Industrial Automation: Any process requiring precise valve actuation and monitoring.

Compatible and Recommended Models

-

Yokogawa A2SDV105-S000 is compatible with pneumatic actuators, linear and rotary valves, and other Yokogawa control modules.

-

Compatible control system interfaces include Yokogawa CENTUM VP, Yokogawa CENTUM CS 3000, and HART-enabled systems.

Installation Instructions

-

Mounting: Secure the positioner directly onto the actuator using the provided bracket, ensuring correct alignment with the valve stem.

-

Air Supply Connection: Connect the clean, dry air supply to the input port. Confirm the pressure is within 0.14–0.7 MPa.

-

Electrical Connection: Connect the 24 V DC power and signal input (4–20 mA).

-

Calibration: Follow the onboard setup procedure using the LCD interface or HART communicator.

-

Testing: Verify stroke output matches the control signal, and check for leaks in the pneumatic lines.

-

Maintenance: Inspect periodically for dust, corrosion, and wear. Replace seals and diaphragms as recommended by the manufacturer.

FAQ

Q1: What is the maximum operating temperature for the A2SDV105-S000?

-

A1: The device operates reliably between -40°C and 85°C.

Q2: Is the A2SDV105-S000 compatible with HART protocol?

-

A2: Yes, it fully supports HART digital communication for integration with process control systems.

Q3: Can this positioner be used with both linear and rotary valves?

-

A3: Yes, it is designed for versatile use with various valve types.

Q4: How accurate is the valve positioning?

-

A4: The accuracy is ±0.5% of span, with repeatability of ±0.2%.

Q5: What maintenance is required for this device?

-

A5: Regular inspection for dust, corrosion, and wear; periodic calibration; replacement of seals if needed.

Q6: What is the air supply requirement?

-

A6: Clean, dry air between 0.14 MPa and 0.7 MPa.

Q7: What materials are used in construction?

-

A7: Aluminum body with stainless steel internal components for durability.

Q8: Can it be used in a high humidity environment?

-

A8: Yes, it can operate in 0–95% RH non-condensing conditions.

Q9: How is the device powered?

-

A9: It operates on 24 V DC supply voltage.

Q10: Is installation complicated?

-

A10: No, it is user-friendly with simple mounting, pneumatic, and electrical connections, and guided calibration steps.

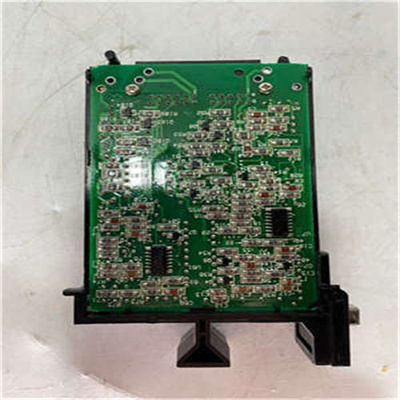

Yokogawa A2SDV105-S000 Digital Input Adapter Module

Manufacturer:Yokogawa

Product Number:A2SDV105-S000

Product Type:Digital Input Adapter Module

Origin:Japan

Dimensions:130 x 12.8 x 40 mm

Weight :0.1 kg

Views:50

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa A2SDV105-S000 is a precision digital valve positioner designed for seamless integration in industrial process control systems. Engineered to enhance control performance and reliability, this valve positioner ensures precise actuator positioning, enabling optimized flow control in a wide range of industrial applications. Its robust design allows for use in harsh environments, maintaining performance under varying temperatures, vibrations, and humidity conditions. The device incorporates advanced diagnostics, providing real-time feedback and ensuring predictive maintenance for process systems.

Product Advantages

-

High Precision Control: Offers accurate positioning for valves, improving process stability and efficiency.

-

Robust Construction: Built to withstand harsh environments, resistant to vibration, temperature extremes, and moisture.

-

Advanced Diagnostics: Provides real-time data and alerts for predictive maintenance, minimizing downtime.

-

Easy Integration: Compatible with a wide range of control systems, supporting HART communication for digital process automation.

-

Energy Efficient: Optimized pneumatic and electronic systems reduce energy consumption.

-

User-Friendly Calibration: Simplifies setup and maintenance through an intuitive interface and clear visual indicators.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | A2SDV105-S000 |

| Type | Digital Valve Positioner |

| Supply Voltage | 24 V DC |

| Communication Protocol | HART |

| Air Supply Pressure | 0.14–0.7 MPa |

| Operating Temperature | -40°C to 85°C |

| Humidity | 0–95% RH, non-condensing |

| Input Signal | 4–20 mA |

| Output Stroke | 0–20 mA or 0–100% |

| Accuracy | ±0.5% of span |

| Repeatability | ±0.2% of span |

| Materials | Aluminum body, stainless steel internals |

| Weight | 0.1 kg |

| Dimensions (L×W×H) | 130 x 12.8 x 40 mm |

Product Applications

-

Petrochemical Industry: Precise flow and pressure control for reactors, distillation columns, and pipelines.

-

Power Plants: Steam and water control in turbines and boilers, ensuring efficient energy conversion.

-

Water Treatment: Accurate chemical dosing and valve control for clean water and wastewater systems.

-

Pharmaceutical Manufacturing: Control of fluid handling systems for consistent production quality.

-

Food & Beverage: Hygienic flow control solutions for liquid processing and packaging lines.

-

General Industrial Automation: Any process requiring precise valve actuation and monitoring.

Compatible and Recommended Models

-

Yokogawa A2SDV105-S000 is compatible with pneumatic actuators, linear and rotary valves, and other Yokogawa control modules.

-

Compatible control system interfaces include Yokogawa CENTUM VP, Yokogawa CENTUM CS 3000, and HART-enabled systems.

Installation Instructions

-

Mounting: Secure the positioner directly onto the actuator using the provided bracket, ensuring correct alignment with the valve stem.

-

Air Supply Connection: Connect the clean, dry air supply to the input port. Confirm the pressure is within 0.14–0.7 MPa.

-

Electrical Connection: Connect the 24 V DC power and signal input (4–20 mA).

-

Calibration: Follow the onboard setup procedure using the LCD interface or HART communicator.

-

Testing: Verify stroke output matches the control signal, and check for leaks in the pneumatic lines.

-

Maintenance: Inspect periodically for dust, corrosion, and wear. Replace seals and diaphragms as recommended by the manufacturer.

FAQ

Q1: What is the maximum operating temperature for the A2SDV105-S000?

-

A1: The device operates reliably between -40°C and 85°C.

Q2: Is the A2SDV105-S000 compatible with HART protocol?

-

A2: Yes, it fully supports HART digital communication for integration with process control systems.

Q3: Can this positioner be used with both linear and rotary valves?

-

A3: Yes, it is designed for versatile use with various valve types.

Q4: How accurate is the valve positioning?

-

A4: The accuracy is ±0.5% of span, with repeatability of ±0.2%.

Q5: What maintenance is required for this device?

-

A5: Regular inspection for dust, corrosion, and wear; periodic calibration; replacement of seals if needed.

Q6: What is the air supply requirement?

-

A6: Clean, dry air between 0.14 MPa and 0.7 MPa.

Q7: What materials are used in construction?

-

A7: Aluminum body with stainless steel internal components for durability.

Q8: Can it be used in a high humidity environment?

-

A8: Yes, it can operate in 0–95% RH non-condensing conditions.

Q9: How is the device powered?

-

A9: It operates on 24 V DC supply voltage.

Q10: Is installation complicated?

-

A10: No, it is user-friendly with simple mounting, pneumatic, and electrical connections, and guided calibration steps.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...