Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

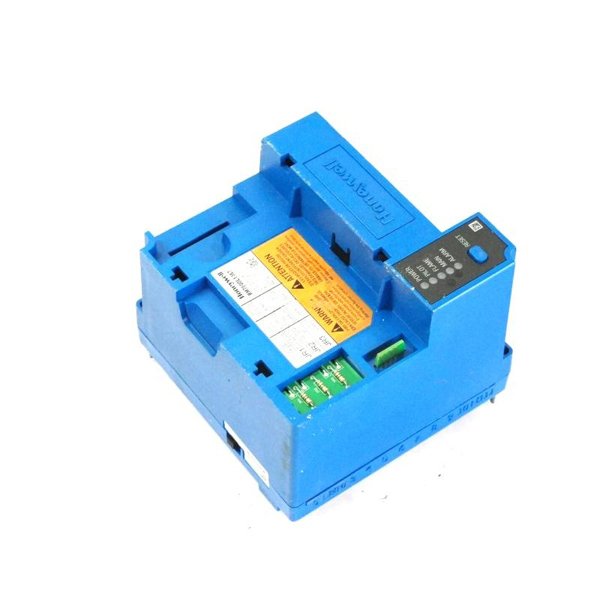

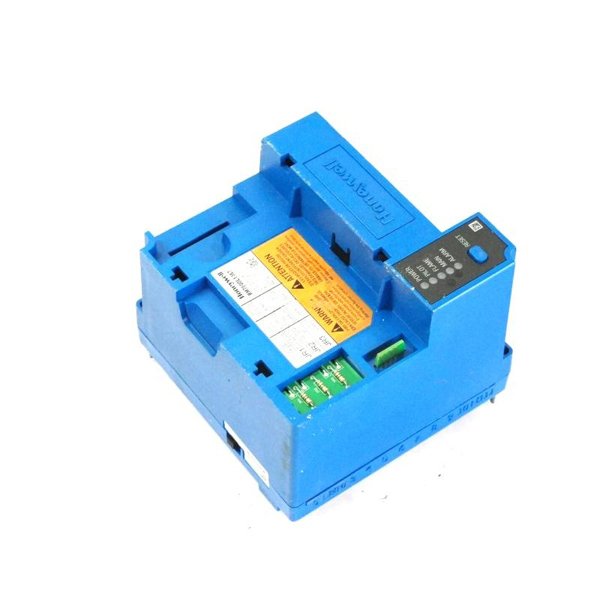

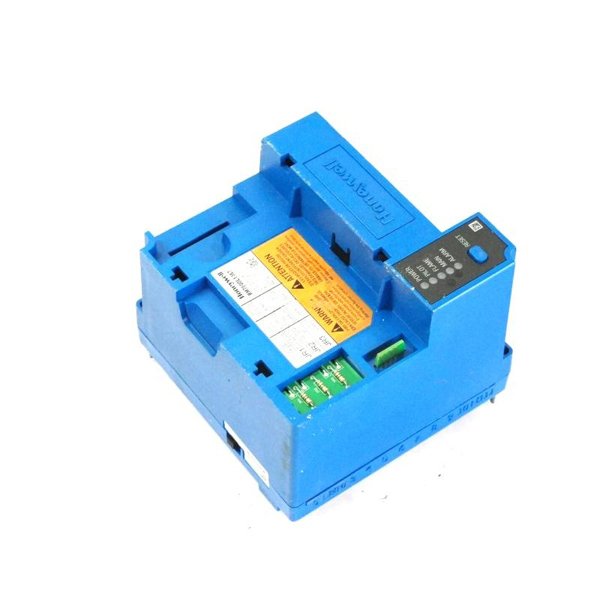

Honeywell RM7800L1087 Burner Control

Manufacturer:Honeywell

Product Number:RM7800L1087

Product Type:Burner Control

Origin:USA

Dimensions:127 x 127 x 133 mm

Weight:0.83 kg

Views:52

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell RM7800L1087 is a microprocessor-based burner control relay module designed for automatic sequencing, flame supervision, system status display, and diagnostics of single-burner gas, oil, or combination fuel applications. It delivers advanced safety and control functions, replacing conventional burner controls.

Product Applications

-

Industrial gas and oil-fired burners

-

Boilers, furnaces, ovens, and kilns

-

Applications requiring SIL3-capable safety instrumentation

-

Systems needing Modbus™ communication and extended diagnostics

-

Single burner systems in commercial and industrial environments

Product Advantages

-

SIL3 capable for high safety integrity

-

Advanced diagnostics and fault history logging

-

Flame failure response time as fast as 0.8 seconds

-

Flexible post purge settings up to 60 minutes

-

Robust safety checks and tamper-resistant logic

-

Modbus™ interface and local/remote annunciation options

-

Nonvolatile memory retains status and history after power loss

Technical Specifications

| Parameter | Specification |

|---|---|

| Dimensions | 127 × 127 × 133 mm |

| Weight | 0.83 kg |

| Operating Voltage | 120 VAC ±10%, 50/60 Hz |

| Power Dissipation | Max 10 W (Relay), Max 3 W (Display) |

| Ambient Temperature | -40°C to +60°C operating |

| Humidity | 85% RH non-condensing |

| Mounting Options | Panel, wall, or burner with subbase |

| Flame Failure Response Time | 0.8 to 3.0 seconds (depending on amplifier) |

| Communication | Optional Modbus™ interface |

| Safety Certification | SIL3 capable, UL, CSA, FM approvals |

FAQ

Q1: What fuel types does the RM7800L1087 support?

A1: It supports gas, oil, or combination fuel systems.

Q2: What is the flame failure response time?

A2: Depending on the amplifier, it ranges from 0.8 to 3.0 seconds.

Q3: Can this module communicate with building management systems?

A3: Yes, through the optional Modbus™ communication module.

Q4: What is the maximum adjustable post purge time?

A4: Up to 60 minutes, with 15 seconds as the default setting.

Q5: Is this product suitable for continuous burner operation?

A5: Yes, it is designed for burners with either intermittent or continuous operation.

Q6: Does it provide fault history logging?

A6: Yes, it records the six most recent faults with detailed data.

Q7: What safety certifications does it have?

A7: UL, CSA, FM, and SIL3 capable in proper configurations.

Q8: What is the maximum load it can handle?

A8: The total connected load is up to 2000 VA with 15A fast-blow fuse protection.

Q9: How is the RM7800L1087 mounted?

A9: Using the Q7800 subbase for panel, wall, or burner mounting.

Q10: Does it retain its settings after a power outage?

A10: Yes, it uses nonvolatile memory to retain history and sequence status.

Honeywell RM7800L1087 Burner Control

Manufacturer:Honeywell

Product Number:RM7800L1087

Product Type:Burner Control

Origin:USA

Dimensions:127 x 127 x 133 mm

Weight:0.83 kg

Views:52

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell RM7800L1087 is a microprocessor-based burner control relay module designed for automatic sequencing, flame supervision, system status display, and diagnostics of single-burner gas, oil, or combination fuel applications. It delivers advanced safety and control functions, replacing conventional burner controls.

Product Applications

-

Industrial gas and oil-fired burners

-

Boilers, furnaces, ovens, and kilns

-

Applications requiring SIL3-capable safety instrumentation

-

Systems needing Modbus™ communication and extended diagnostics

-

Single burner systems in commercial and industrial environments

Product Advantages

-

SIL3 capable for high safety integrity

-

Advanced diagnostics and fault history logging

-

Flame failure response time as fast as 0.8 seconds

-

Flexible post purge settings up to 60 minutes

-

Robust safety checks and tamper-resistant logic

-

Modbus™ interface and local/remote annunciation options

-

Nonvolatile memory retains status and history after power loss

Technical Specifications

| Parameter | Specification |

|---|---|

| Dimensions | 127 × 127 × 133 mm |

| Weight | 0.83 kg |

| Operating Voltage | 120 VAC ±10%, 50/60 Hz |

| Power Dissipation | Max 10 W (Relay), Max 3 W (Display) |

| Ambient Temperature | -40°C to +60°C operating |

| Humidity | 85% RH non-condensing |

| Mounting Options | Panel, wall, or burner with subbase |

| Flame Failure Response Time | 0.8 to 3.0 seconds (depending on amplifier) |

| Communication | Optional Modbus™ interface |

| Safety Certification | SIL3 capable, UL, CSA, FM approvals |

FAQ

Q1: What fuel types does the RM7800L1087 support?

A1: It supports gas, oil, or combination fuel systems.

Q2: What is the flame failure response time?

A2: Depending on the amplifier, it ranges from 0.8 to 3.0 seconds.

Q3: Can this module communicate with building management systems?

A3: Yes, through the optional Modbus™ communication module.

Q4: What is the maximum adjustable post purge time?

A4: Up to 60 minutes, with 15 seconds as the default setting.

Q5: Is this product suitable for continuous burner operation?

A5: Yes, it is designed for burners with either intermittent or continuous operation.

Q6: Does it provide fault history logging?

A6: Yes, it records the six most recent faults with detailed data.

Q7: What safety certifications does it have?

A7: UL, CSA, FM, and SIL3 capable in proper configurations.

Q8: What is the maximum load it can handle?

A8: The total connected load is up to 2000 VA with 15A fast-blow fuse protection.

Q9: How is the RM7800L1087 mounted?

A9: Using the Q7800 subbase for panel, wall, or burner mounting.

Q10: Does it retain its settings after a power outage?

A10: Yes, it uses nonvolatile memory to retain history and sequence status.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...