Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

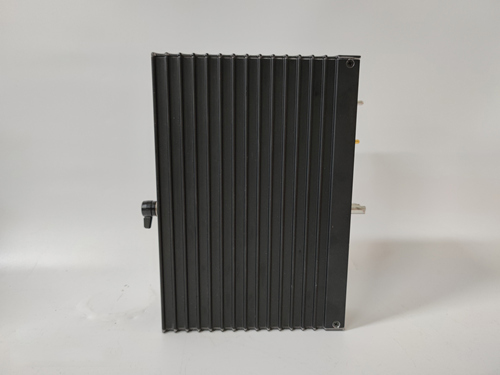

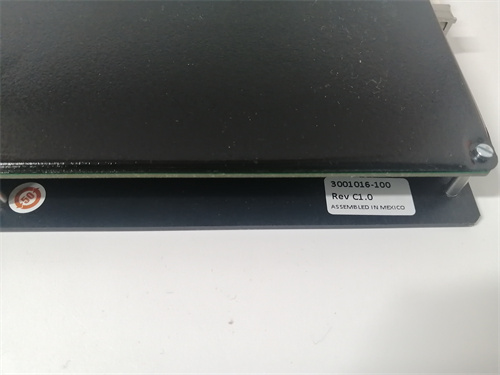

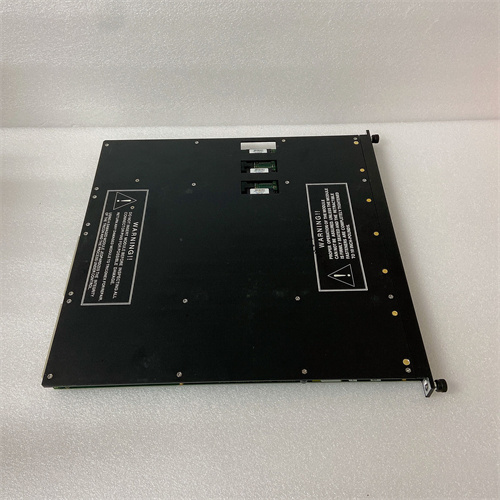

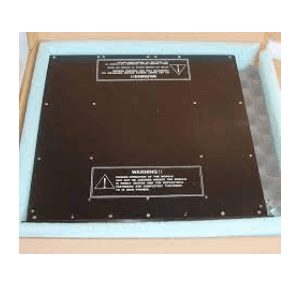

Triconex 8111 PLC Rack Chassis

Product Description

The Triconex 8111 Expansion Chassis enables the integration of additional I/O and communication modules into the system.

You can incorporate extra I/O and communication modules within a system. The 8111 Expansion Chassis comprises two power modules and eight logic slots for I/O and communication modules (communication modules are only accommodated in Expansion Chassis 2). You can use the expansion chassis when the total length of the I/O bus in the system is 1.5 meters.

The cable length from the main chassis to the expansion chassis does not exceed 100 feet (30 meters).

Key Features of the Tricon System

To ensure system integrity at all times, the Tricon system boasts the following features:

- Provides a triple-module redundancy structure, with three identical sub-circuits independently executing control functions. It features dedicated hardware/software structures for input and output voting.

- Withstands harsh industrial environments.

- Supports on-site installation, allowing for module-level installation and repairs without disrupting field wiring.

- Supports up to 118 I/O modules (analog and digital) and optional communication modules. Communication modules can connect with Modbus masters and slaves, Foxboro and Honeywell distributed control systems (DCS), other Tricon units in a peer-to-peer network, and external hosts on TCP/IP networks.

- Can accommodate remote I/O modules located up to 12 kilometers (7.5 miles) away from the main rack.

- Utilizes programming software based on the WINDOWS system for control program development and debugging.

- Features intelligent capabilities within input and output modules, alleviating the workload of the main processor. Each I/O module includes three microprocessors. The microprocessor in the input module filters and repairs inputs, diagnoses hardware faults on the module. The output module microprocessor provides voting information for output data, checks the validity of output states through feedback loop voltages at the output terminals, and diagnoses field circuit issues.

- Offers comprehensive online diagnostics and repair capabilities.

- Allows routine maintenance during normal Tricon operation without interrupting control processes.

- Provides “hot standby” support for I/O modules, suitable for critical situations where timely service is challenging.

Triconex 8111 PLC Rack Chassis

Product Description

The Triconex 8111 Expansion Chassis enables the integration of additional I/O and communication modules into the system.

You can incorporate extra I/O and communication modules within a system. The 8111 Expansion Chassis comprises two power modules and eight logic slots for I/O and communication modules (communication modules are only accommodated in Expansion Chassis 2). You can use the expansion chassis when the total length of the I/O bus in the system is 1.5 meters.

The cable length from the main chassis to the expansion chassis does not exceed 100 feet (30 meters).

Key Features of the Tricon System

To ensure system integrity at all times, the Tricon system boasts the following features:

- Provides a triple-module redundancy structure, with three identical sub-circuits independently executing control functions. It features dedicated hardware/software structures for input and output voting.

- Withstands harsh industrial environments.

- Supports on-site installation, allowing for module-level installation and repairs without disrupting field wiring.

- Supports up to 118 I/O modules (analog and digital) and optional communication modules. Communication modules can connect with Modbus masters and slaves, Foxboro and Honeywell distributed control systems (DCS), other Tricon units in a peer-to-peer network, and external hosts on TCP/IP networks.

- Can accommodate remote I/O modules located up to 12 kilometers (7.5 miles) away from the main rack.

- Utilizes programming software based on the WINDOWS system for control program development and debugging.

- Features intelligent capabilities within input and output modules, alleviating the workload of the main processor. Each I/O module includes three microprocessors. The microprocessor in the input module filters and repairs inputs, diagnoses hardware faults on the module. The output module microprocessor provides voting information for output data, checks the validity of output states through feedback loop voltages at the output terminals, and diagnoses field circuit issues.

- Offers comprehensive online diagnostics and repair capabilities.

- Allows routine maintenance during normal Tricon operation without interrupting control processes.

- Provides “hot standby” support for I/O modules, suitable for critical situations where timely service is challenging.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...