Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

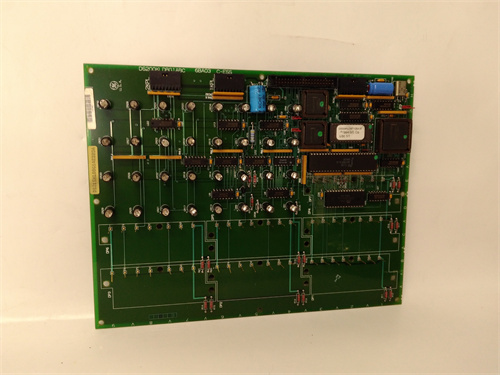

GE IS220PSVOH1A Mark VIe Servo Pack

Manufacturer: GE Fanuc

Product No.: IS220PSVOH1A

Condition: Brand NEW & in Stock

Product Type: IS220PSVOH1A

Product Origin: United States

Payment: T/T, Western Union

Dimension:16cm x 16cm x 12cm (6.3″ x 6.3″ x 4.7″)

Weight: 0.8kg (1.8 lbs)

Approvals: CE, UL, CSA

Warranty: 12 months

Product Description

The IS220PSVOH1A is a key component in GE’s Mark VIe control systems, specifically designed for steam and gas turbine applications.

Type: An I/O (Input/Output) module, acting as a bridge between control networks and servo systems.

Features

- Connects one or two Ethernet networks to a TSVO servo terminal board.

- Manages two servo valve position loops using WSVO servo driver modules.

- Provides real-time communication between control systems and servo actuators.

- Offers status indication via LED lights for power, network activity, and more.

Technical Specifications:

- Supports a wide ambient temperature range (-30°C to 65°C).

- Configurable using GE’s Control System Toolbox software.

- Includes self-diagnostics for enhanced system reliability.

The IS220PSVOH1A Servo Control Pack under the Mark VIe series, developed by GE, is designed for controlling steam and gas turbine systems. Here are the key details about the IS220PSVOH1A:

Other information

- Electrical Interface: Connects a TSVO servo terminal board to one or two I/O Ethernet networks.

- Servo Driver Module: Uses a WSVO servo driver module to control two servo valve position loops.

- Front Faceplate: Equipped with various LED indications:

- Four LEDs display the state of two Ethernet networks (ENet1/ENet2).

- Power and Attention (Attn) LEDs.

- Two ENA1/2 LEDs.

- An infrared port (not used in this pack).

- Components:

- CPU board with input power connectors, local power supply, and an internal temperature sensor.

- Flash memory and RAM.

- Configuration:

- Setup using the Control System Toolbox application.

- Features auto-reconfiguration which can be activated or disabled in the ToolboxST application’s Component Editor.

- Manual reconfiguration required when a terminal board is changed.

- Testing:

- Servo performance testing options include stroking the actuator in manual mode, position ramping, or step current.

- Irregularities in the actuator stroke can be displayed on the trend recorder.

Installation and Operation

- The IS220PSVOH1A can be set up and configured using the Control System Toolbox application.

- It has a CPU board linked to a purchase board, containing input power connectors, a local power supply, and an internal temperature sensor.

- Manufacturer user guides and manuals provide detailed information about the installation, operation, and potential compatibility issues.

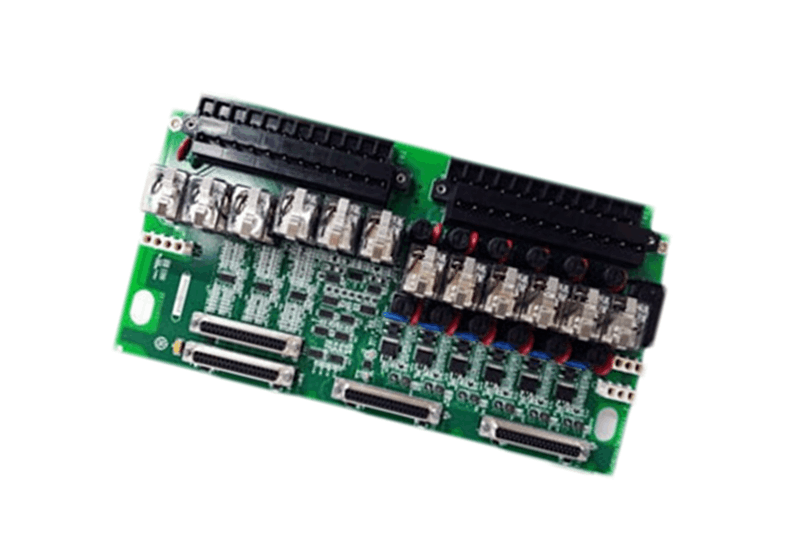

GE IS220PSVOH1A Mark VIe Servo Pack

Manufacturer: GE Fanuc

Product No.: IS220PSVOH1A

Condition: Brand NEW & in Stock

Product Type: IS220PSVOH1A

Product Origin: United States

Payment: T/T, Western Union

Dimension:16cm x 16cm x 12cm (6.3″ x 6.3″ x 4.7″)

Weight: 0.8kg (1.8 lbs)

Approvals: CE, UL, CSA

Warranty: 12 months

Product Description

The IS220PSVOH1A is a key component in GE’s Mark VIe control systems, specifically designed for steam and gas turbine applications.

Type: An I/O (Input/Output) module, acting as a bridge between control networks and servo systems.

Features

- Connects one or two Ethernet networks to a TSVO servo terminal board.

- Manages two servo valve position loops using WSVO servo driver modules.

- Provides real-time communication between control systems and servo actuators.

- Offers status indication via LED lights for power, network activity, and more.

Technical Specifications:

- Supports a wide ambient temperature range (-30°C to 65°C).

- Configurable using GE’s Control System Toolbox software.

- Includes self-diagnostics for enhanced system reliability.

The IS220PSVOH1A Servo Control Pack under the Mark VIe series, developed by GE, is designed for controlling steam and gas turbine systems. Here are the key details about the IS220PSVOH1A:

Other information

- Electrical Interface: Connects a TSVO servo terminal board to one or two I/O Ethernet networks.

- Servo Driver Module: Uses a WSVO servo driver module to control two servo valve position loops.

- Front Faceplate: Equipped with various LED indications:

- Four LEDs display the state of two Ethernet networks (ENet1/ENet2).

- Power and Attention (Attn) LEDs.

- Two ENA1/2 LEDs.

- An infrared port (not used in this pack).

- Components:

- CPU board with input power connectors, local power supply, and an internal temperature sensor.

- Flash memory and RAM.

- Configuration:

- Setup using the Control System Toolbox application.

- Features auto-reconfiguration which can be activated or disabled in the ToolboxST application’s Component Editor.

- Manual reconfiguration required when a terminal board is changed.

- Testing:

- Servo performance testing options include stroking the actuator in manual mode, position ramping, or step current.

- Irregularities in the actuator stroke can be displayed on the trend recorder.

Installation and Operation

- The IS220PSVOH1A can be set up and configured using the Control System Toolbox application.

- It has a CPU board linked to a purchase board, containing input power connectors, a local power supply, and an internal temperature sensor.

- Manufacturer user guides and manuals provide detailed information about the installation, operation, and potential compatibility issues.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...