Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

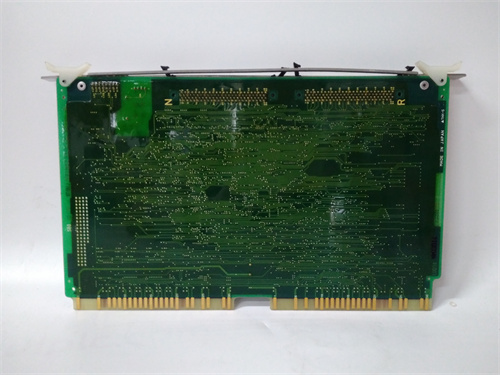

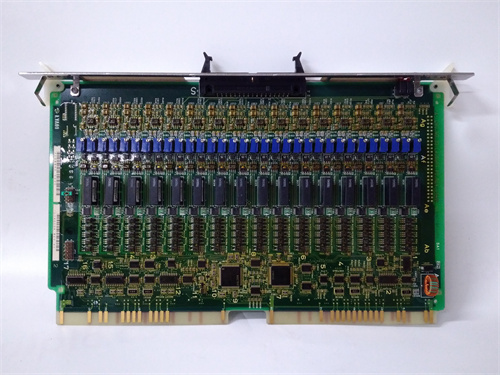

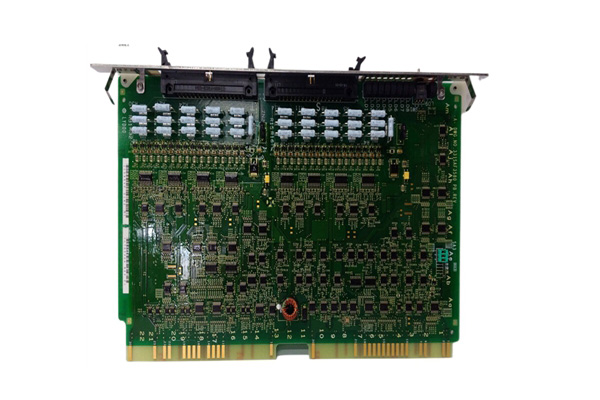

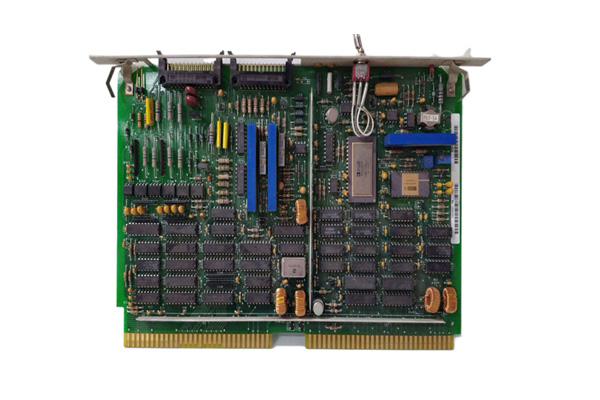

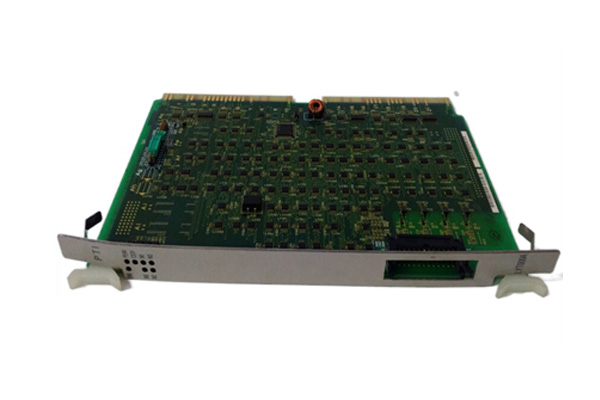

Hitachi LYD105A Servo Controller

Module Number:LYD105A

Working voltage: 5V DC

Working current: 50mA

Communication interface: UART

Baud rate: 9600bps

Storage temperature: -40 ℃~85 ℃

Working temperature: -20 ℃~70 ℃

Product Description

HITACHI LYD105A is a servo controller mainly used to control servo motors and perform high-precision motion control tasks. The following is a detailed introduction to the HITACHI LYD105A servo controller:

Functional features

Precision motion control: The LYD105A servo controller has high-precision motion control capabilities, ensuring that the servo motor achieves precise position control and speed adjustment.

Multi axis control: It supports the control of multiple servo motors or axes, and can simultaneously control the movement of multiple axes, thereby achieving complex motion paths.

Programming and configuration: Use specific programming languages or tools to program and configure motion trajectories, velocity curves, and motion parameters.

Communication Interface: Equipped with communication interfaces, it can communicate and integrate data with other control systems, PLCs, HMI interfaces, or monitoring devices.

Safety function: Some models may have safety functions for achieving safety monitoring and fault diagnosis of mechanical systems.

Durability: With industrial grade durability, it can operate stably in harsh industrial environments and resist conditions such as vibration, humidity, and temperature changes.

Application field

Widely used in industrial automation, manufacturing, mechanical processing, printing, packaging and other fields.

It is also used to achieve high-precision motion control in robot systems, medical equipment, semiconductor manufacturing, and other fields.

Technical specifications

Working voltage: 5V DC

Working current: 50mA

Communication interface: UART

Baud rate: 9600bps

Storage temperature: -40 ℃~85 ℃

Working temperature: -20 ℃~70 ℃

The above information is for reference only. If you need more detailed information or technical support, we suggest that you directly contact HITACHI’s official channels or relevant suppliers.

Hitachi LYD105A Servo Controller

Module Number:LYD105A

Working voltage: 5V DC

Working current: 50mA

Communication interface: UART

Baud rate: 9600bps

Storage temperature: -40 ℃~85 ℃

Working temperature: -20 ℃~70 ℃

Product Description

HITACHI LYD105A is a servo controller mainly used to control servo motors and perform high-precision motion control tasks. The following is a detailed introduction to the HITACHI LYD105A servo controller:

Functional features

Precision motion control: The LYD105A servo controller has high-precision motion control capabilities, ensuring that the servo motor achieves precise position control and speed adjustment.

Multi axis control: It supports the control of multiple servo motors or axes, and can simultaneously control the movement of multiple axes, thereby achieving complex motion paths.

Programming and configuration: Use specific programming languages or tools to program and configure motion trajectories, velocity curves, and motion parameters.

Communication Interface: Equipped with communication interfaces, it can communicate and integrate data with other control systems, PLCs, HMI interfaces, or monitoring devices.

Safety function: Some models may have safety functions for achieving safety monitoring and fault diagnosis of mechanical systems.

Durability: With industrial grade durability, it can operate stably in harsh industrial environments and resist conditions such as vibration, humidity, and temperature changes.

Application field

Widely used in industrial automation, manufacturing, mechanical processing, printing, packaging and other fields.

It is also used to achieve high-precision motion control in robot systems, medical equipment, semiconductor manufacturing, and other fields.

Technical specifications

Working voltage: 5V DC

Working current: 50mA

Communication interface: UART

Baud rate: 9600bps

Storage temperature: -40 ℃~85 ℃

Working temperature: -20 ℃~70 ℃

The above information is for reference only. If you need more detailed information or technical support, we suggest that you directly contact HITACHI’s official channels or relevant suppliers.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...