Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

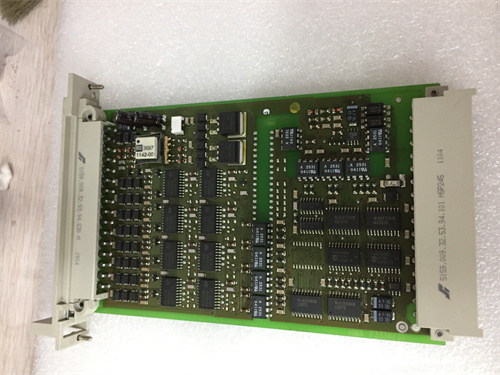

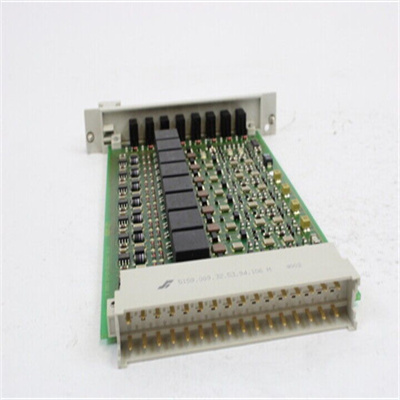

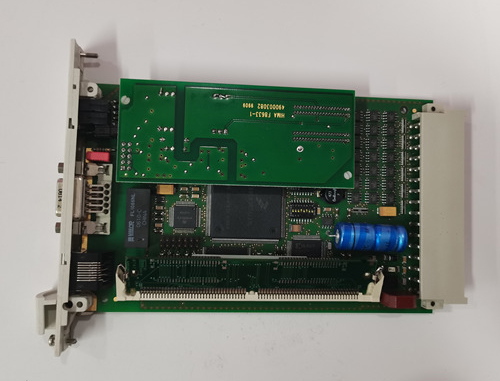

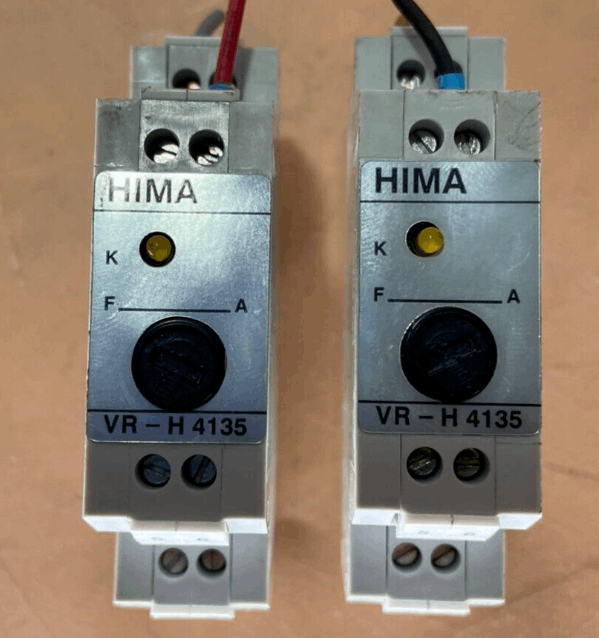

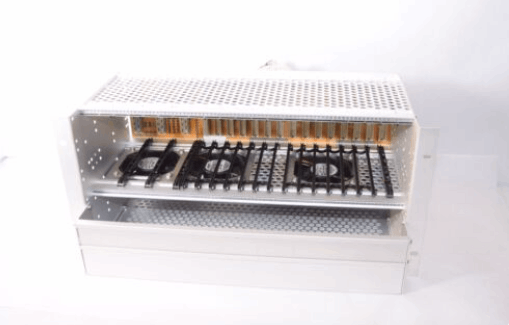

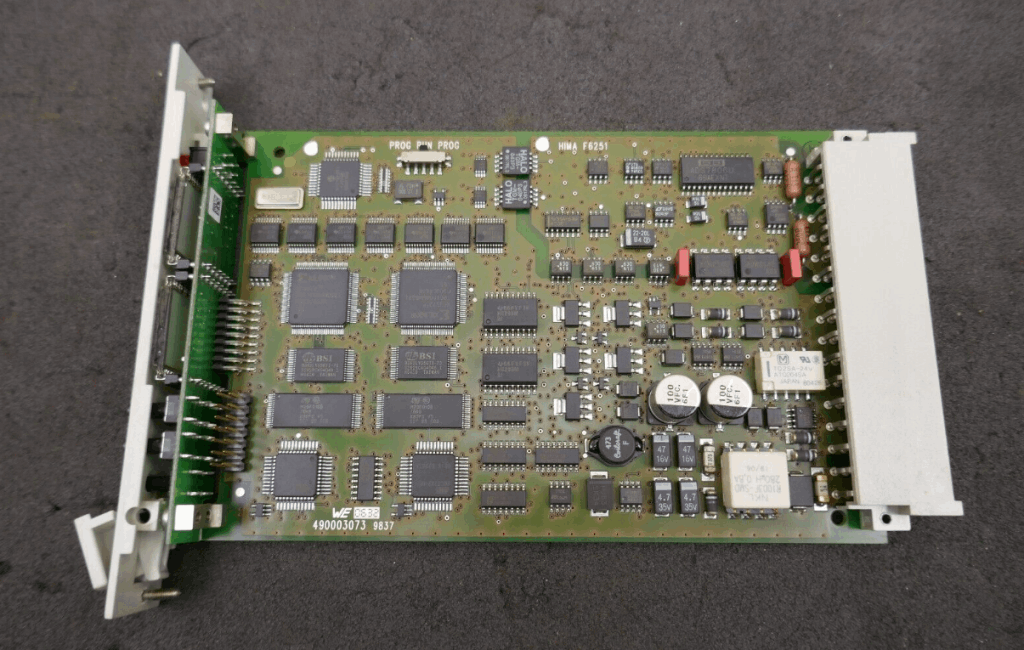

Hima F2108 Safety Related Multifunctional Delay Module

ManufacturerHIMA:HIMA

Product Number:F2108

Product Type:Safety Related Multifunctional Delay Module

Origin:Germany

Dimensions:160 x 120 mm

Weight:0.8 kg

Views:66

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The HIMA F2108 Safety-Related Multifunctional Delay Module is a high-precision, safety-certified timing module designed for critical industrial applications. It provides reliable time-delay functions for safety-related processes, ensuring that systems respond correctly within pre-defined timeframes. This module is an integral part of HIMA’s safety automation systems, which are widely used in industries such as oil & gas, chemical processing, power generation, and manufacturing.

With its SIL3 certification, the F2108 guarantees high reliability and fault tolerance, making it an ideal choice for applications that require precise control over delayed activation and deactivation of safety functions. Its flexible configuration allows it to be adapted to various safety automation tasks, including emergency shutdowns (ESD), alarm sequencing, and controlled process timing.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | HIMA F2108 Safety-Related Multifunctional Delay Module |

| Function | Safety-related time delay control module |

| Input Voltage | 24V DC (nominal) |

| Power Consumption | Approx. 3.5W |

| Timer Functions | Delay-on, delay-off, pulse generation, interval timing |

| Response Time | < 5 ms |

| Operating Temperature | -25°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% non-condensing |

| Mounting | DIN rail mounting |

| Safety Certification | SIL3 (IEC 61508) |

| Communication Interface | Compatible with HIMA safety systems |

| Dimensions | 160 x 120 mm |

| Weight | 0.8 kg |

| Compliance | IEC 61508, EN 50156-1, ATEX certified |

Applications

The HIMA F2108 is widely used in industrial and safety-critical applications requiring precise timing control. Key application areas include:

1. Emergency Shutdown (ESD) Systems

- Ensures a controlled delay before activating an emergency shutdown sequence to prevent unnecessary system trips.

2. Process Safety in Chemical and Petrochemical Industries

- Used to manage time-based safety interlocks, ensuring critical reactions occur in a controlled sequence.

3. Power Plant Automation

- Provides precise delay timing in turbine control systems, preventing premature shutdowns or system faults.

4. Oil & Gas Industry

- Used in offshore and onshore facilities for pipeline safety and flare system control.

5. Alarm & Notification Sequencing

- Implements controlled delays for alarm activations to avoid unnecessary disturbances and false alarms.

6. Industrial Automation & Manufacturing

- Controls the timed operation of safety devices such as emergency stops, protective barriers, and machine interlocks.

Advantages of HIMA F2108

- High Safety Certification (SIL3) – Ensures reliability in mission-critical safety applications.

- Multifunctional Timer Capabilities – Supports multiple timing functions such as delay-on, delay-off, pulse timing, and interval timing.

- Fast Response Time (<5ms) – Ensures accurate and quick reaction in emergency and automation processes.

- Wide Operating Temperature Range (-25°C to +70°C) – Suitable for harsh industrial environments.

- Energy Efficient (3.5W Power Consumption) – Reduces overall energy costs and system heat generation.

- Compact DIN Rail Mounting – Space-saving design for easy integration into control panels.

- Compatible with HIMA Safety Systems – Seamless integration with other HIMA automation and safety modules.

- Fault-Tolerant Design – Minimizes risks of failure in safety applications, ensuring continuous operation.

- Easy Configuration & Maintenance – Configurable via HIMA’s proprietary software tools, allowing for quick setup.

- Certified for Hazardous Environments – Complies with IEC 61508 and ATEX standards for use in explosive atmospheres.

Hima F2108 Safety Related Multifunctional Delay Module

ManufacturerHIMA:HIMA

Product Number:F2108

Product Type:Safety Related Multifunctional Delay Module

Origin:Germany

Dimensions:160 x 120 mm

Weight:0.8 kg

Views:66

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The HIMA F2108 Safety-Related Multifunctional Delay Module is a high-precision, safety-certified timing module designed for critical industrial applications. It provides reliable time-delay functions for safety-related processes, ensuring that systems respond correctly within pre-defined timeframes. This module is an integral part of HIMA’s safety automation systems, which are widely used in industries such as oil & gas, chemical processing, power generation, and manufacturing.

With its SIL3 certification, the F2108 guarantees high reliability and fault tolerance, making it an ideal choice for applications that require precise control over delayed activation and deactivation of safety functions. Its flexible configuration allows it to be adapted to various safety automation tasks, including emergency shutdowns (ESD), alarm sequencing, and controlled process timing.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | HIMA F2108 Safety-Related Multifunctional Delay Module |

| Function | Safety-related time delay control module |

| Input Voltage | 24V DC (nominal) |

| Power Consumption | Approx. 3.5W |

| Timer Functions | Delay-on, delay-off, pulse generation, interval timing |

| Response Time | < 5 ms |

| Operating Temperature | -25°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% non-condensing |

| Mounting | DIN rail mounting |

| Safety Certification | SIL3 (IEC 61508) |

| Communication Interface | Compatible with HIMA safety systems |

| Dimensions | 160 x 120 mm |

| Weight | 0.8 kg |

| Compliance | IEC 61508, EN 50156-1, ATEX certified |

Applications

The HIMA F2108 is widely used in industrial and safety-critical applications requiring precise timing control. Key application areas include:

1. Emergency Shutdown (ESD) Systems

- Ensures a controlled delay before activating an emergency shutdown sequence to prevent unnecessary system trips.

2. Process Safety in Chemical and Petrochemical Industries

- Used to manage time-based safety interlocks, ensuring critical reactions occur in a controlled sequence.

3. Power Plant Automation

- Provides precise delay timing in turbine control systems, preventing premature shutdowns or system faults.

4. Oil & Gas Industry

- Used in offshore and onshore facilities for pipeline safety and flare system control.

5. Alarm & Notification Sequencing

- Implements controlled delays for alarm activations to avoid unnecessary disturbances and false alarms.

6. Industrial Automation & Manufacturing

- Controls the timed operation of safety devices such as emergency stops, protective barriers, and machine interlocks.

Advantages of HIMA F2108

- High Safety Certification (SIL3) – Ensures reliability in mission-critical safety applications.

- Multifunctional Timer Capabilities – Supports multiple timing functions such as delay-on, delay-off, pulse timing, and interval timing.

- Fast Response Time (<5ms) – Ensures accurate and quick reaction in emergency and automation processes.

- Wide Operating Temperature Range (-25°C to +70°C) – Suitable for harsh industrial environments.

- Energy Efficient (3.5W Power Consumption) – Reduces overall energy costs and system heat generation.

- Compact DIN Rail Mounting – Space-saving design for easy integration into control panels.

- Compatible with HIMA Safety Systems – Seamless integration with other HIMA automation and safety modules.

- Fault-Tolerant Design – Minimizes risks of failure in safety applications, ensuring continuous operation.

- Easy Configuration & Maintenance – Configurable via HIMA’s proprietary software tools, allowing for quick setup.

- Certified for Hazardous Environments – Complies with IEC 61508 and ATEX standards for use in explosive atmospheres.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...