Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

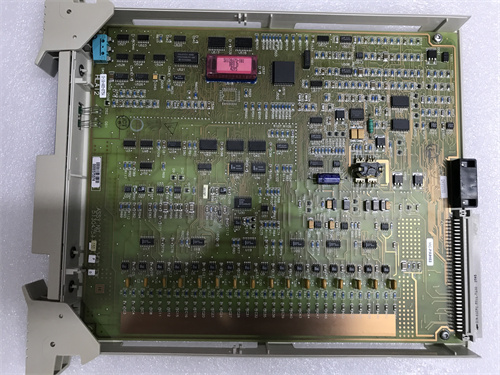

Honeywell 900S75-0460 ControlEdge HC900 Scanner

Manufacturer:Honeywell

Product Number:900S75-0460

Product Type:ControlEdge HC900 Scanner

Origin:USA

Dimensions:137 × 38.1 × 137.16 mm

Weight:0.4 kg

Views:83

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell 900S75-0460 is a dual-port scanner module designed for the ControlEdge HC900 Process and Safety System. It enables distributed I/O architecture by allowing a controller to communicate with remote I/O racks over Ethernet. The scanner module plays a critical role in expanding system scalability, improving flexibility, and facilitating high-speed data exchange between multiple nodes.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 900S75-0460 |

| Product Type | Dual-Port Scanner Module |

| Platform Compatibility | ControlEdge HC900 |

| Communication Ports | 2 × Ethernet Ports |

| Communication Protocol | Ethernet/IP or proprietary HC900 protocol |

| Power Consumption | 5.0 W typical |

| Operating Temperature | 0°C to 60°C (32°F to 140°F) |

| Storage Temperature | -40°C to 70°C (-40°F to 158°F) |

| Relative Humidity | 10%–90% non-condensing |

| Mounting Type | DIN Rail Mount |

| Dimensions (H × W × D) | 137 × 38.1 × 137.16 mm |

| Weight | 0.4 kg |

| Certification | CE, UL, CSA, FM, ATEX |

Applications

-

Distributed I/O communication in complex industrial process control systems

-

Integration of remote I/O for chemical, power, and pharmaceutical plants

-

Safety systems where redundancy and dual-port access are required

-

Scalable automation architecture supporting high-speed data acquisition

-

Remote operations for modular field stations

Product Advantages

Dual Ethernet Ports: Provides redundancy and fast communication.

Hot Swap Capable: Modules can be replaced without system shutdown.

Auto-Configuration: Automatic module detection and setup.

Robust Diagnostics: Supports module fault and override indication.

Environmental Resilience: Conformal coating allows operation in harsh G3-level conditions.

Global Certifications: Suitable for use in hazardous industrial environments.

Frequently Asked Questions (FAQ)

Q1: What is the main function of the 900S75-0460 Scanner?

A1: It enables a controller to communicate with remote I/O racks via dual Ethernet ports for distributed control.

Q2: Can the 900S75-0460 be inserted or removed while powered?

A2: Yes, it supports hot-swapping under power for easier maintenance.

Q3: Is the scanner suitable for hazardous environments?

A3: Yes, it holds FM, CSA, UL, and ATEX certifications for such applications.

Q4: What kind of I/O modules can it communicate with?

A4: All ControlEdge HC900 I/O modules, including analog, digital, and relay modules.

Q5: What configuration software is used?

A5: Honeywell Process Control Designer (PCD) is used for configuration.

Q6: Is it compatible with redundant controller configurations?

A6: Yes, it supports use in redundant systems for increased reliability.

Q7: What is the recommended mounting method?

A7: It is designed for standard 35 mm DIN rail mounting.

Q8: What is the weight of the 900S75-0460 module?

A8: It weighs approximately 0.4 kg.

Q9: What kind of status indicators does the module provide?

A9: Tri-color LED status indicators: green (OK), red (Fault), amber (Override).

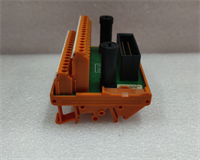

Q10: Does it require a specific terminal block?

A10: Yes, it uses Euro-style terminal blocks appropriate to the module type.

Honeywell 900S75-0460 ControlEdge HC900 Scanner

Manufacturer:Honeywell

Product Number:900S75-0460

Product Type:ControlEdge HC900 Scanner

Origin:USA

Dimensions:137 × 38.1 × 137.16 mm

Weight:0.4 kg

Views:83

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell 900S75-0460 is a dual-port scanner module designed for the ControlEdge HC900 Process and Safety System. It enables distributed I/O architecture by allowing a controller to communicate with remote I/O racks over Ethernet. The scanner module plays a critical role in expanding system scalability, improving flexibility, and facilitating high-speed data exchange between multiple nodes.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 900S75-0460 |

| Product Type | Dual-Port Scanner Module |

| Platform Compatibility | ControlEdge HC900 |

| Communication Ports | 2 × Ethernet Ports |

| Communication Protocol | Ethernet/IP or proprietary HC900 protocol |

| Power Consumption | 5.0 W typical |

| Operating Temperature | 0°C to 60°C (32°F to 140°F) |

| Storage Temperature | -40°C to 70°C (-40°F to 158°F) |

| Relative Humidity | 10%–90% non-condensing |

| Mounting Type | DIN Rail Mount |

| Dimensions (H × W × D) | 137 × 38.1 × 137.16 mm |

| Weight | 0.4 kg |

| Certification | CE, UL, CSA, FM, ATEX |

Applications

-

Distributed I/O communication in complex industrial process control systems

-

Integration of remote I/O for chemical, power, and pharmaceutical plants

-

Safety systems where redundancy and dual-port access are required

-

Scalable automation architecture supporting high-speed data acquisition

-

Remote operations for modular field stations

Product Advantages

Dual Ethernet Ports: Provides redundancy and fast communication.

Hot Swap Capable: Modules can be replaced without system shutdown.

Auto-Configuration: Automatic module detection and setup.

Robust Diagnostics: Supports module fault and override indication.

Environmental Resilience: Conformal coating allows operation in harsh G3-level conditions.

Global Certifications: Suitable for use in hazardous industrial environments.

Frequently Asked Questions (FAQ)

Q1: What is the main function of the 900S75-0460 Scanner?

A1: It enables a controller to communicate with remote I/O racks via dual Ethernet ports for distributed control.

Q2: Can the 900S75-0460 be inserted or removed while powered?

A2: Yes, it supports hot-swapping under power for easier maintenance.

Q3: Is the scanner suitable for hazardous environments?

A3: Yes, it holds FM, CSA, UL, and ATEX certifications for such applications.

Q4: What kind of I/O modules can it communicate with?

A4: All ControlEdge HC900 I/O modules, including analog, digital, and relay modules.

Q5: What configuration software is used?

A5: Honeywell Process Control Designer (PCD) is used for configuration.

Q6: Is it compatible with redundant controller configurations?

A6: Yes, it supports use in redundant systems for increased reliability.

Q7: What is the recommended mounting method?

A7: It is designed for standard 35 mm DIN rail mounting.

Q8: What is the weight of the 900S75-0460 module?

A8: It weighs approximately 0.4 kg.

Q9: What kind of status indicators does the module provide?

A9: Tri-color LED status indicators: green (OK), red (Fault), amber (Override).

Q10: Does it require a specific terminal block?

A10: Yes, it uses Euro-style terminal blocks appropriate to the module type.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...