Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

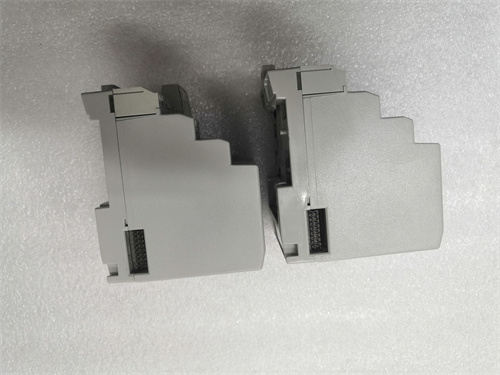

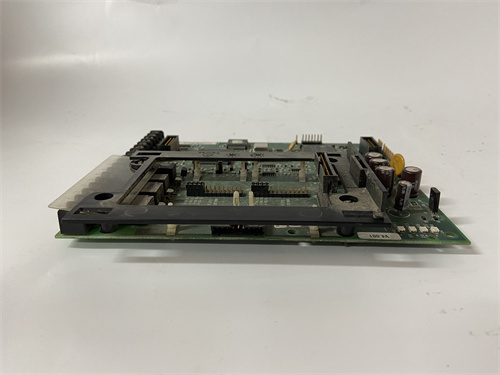

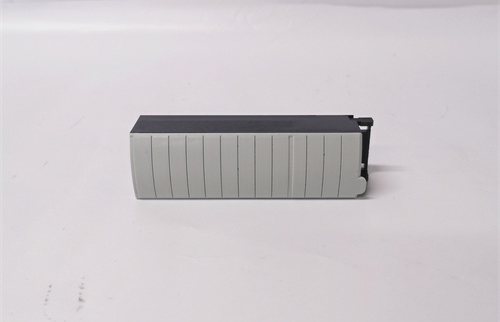

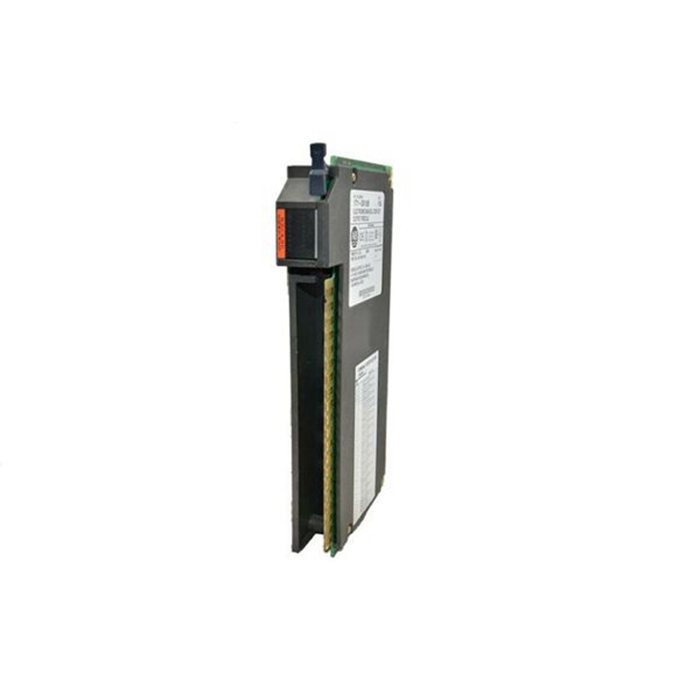

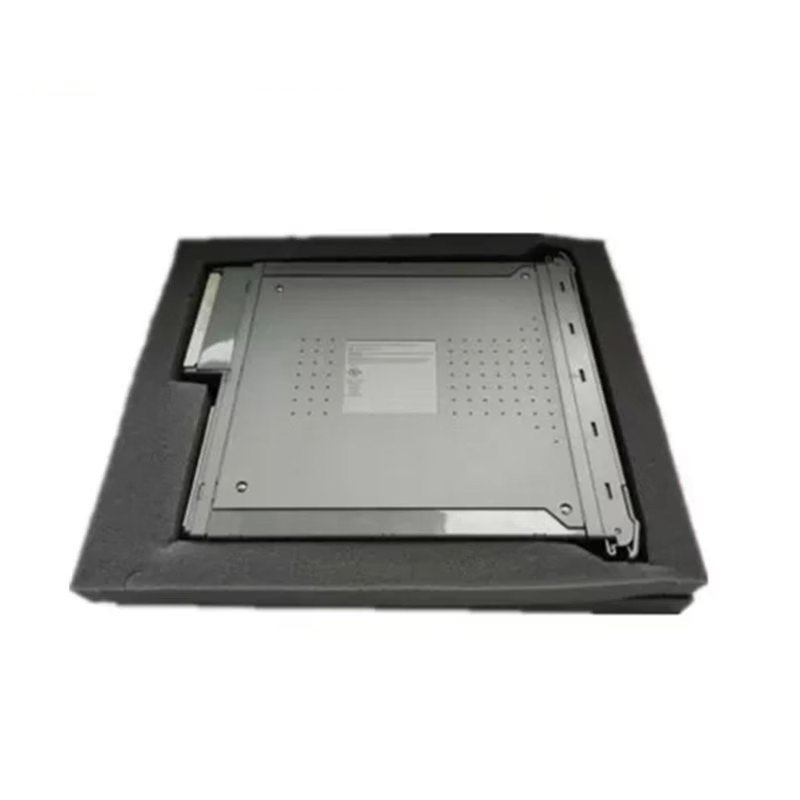

Allen-Bradley 1756-A13 ControlLogix Chassis

Brand: Allen Bradley

Number of slots: 13

Backplane current capacity: 10A per slot, 15A per slot with power supply redundancy

Power supply options: Single or redundant power supplies

Communication options: EtherNet/IP, ControlNet, DeviceNet, and other communication modules

Dimensions: 9.05″ H x 17.44″ W x 8.27″ D

Weight: 8.8 lbs (4.0 kg)l

Product Description

The Allen-Bradley 1756-A13 ControlLogix Chassis is an essential component of the ControlLogix system, providing a sturdy and reliable platform for multiple ControlLogix modules. Here are its features, applications, technical specifications, and benefits.

Features

- 13 slot capacity for ControlLogix modules

- Compact design for easy installation and integration

- High-quality construction for reliable performance

- Integrated safety features for protecting personnel and equipment

- Hot-swappable modules for easy maintenance and upgrades

Applications

- Industrial automation and control systems

- Process control and monitoring

- Material handling and assembly line control

- Robotics and machine control

- Building automation and HVAC control

Technical Specifications

- Number of slots: 13

- Backplane current capacity: 10A per slot, 15A per slot with power supply redundancy

- Power supply options: Single or redundant power supplies

- Communication options: EtherNet/IP, ControlNet, DeviceNet, and other communication modules

- Dimensions: 9.05″ H x 17.44″ W x 8.27″ D

- Weight: 8.8 lbs (4.0 kg)

Benefits

- Flexible and scalable platform for industrial control applications

- High-quality construction ensures reliable and long-lasting performance

- Integrated safety features protect personnel and equipment

- Hot-swappable modules reduce downtime and maintenance costs

- Compact design saves space and simplifies installation and integration

In summary, the Allen-Bradley 1756-A13 ControlLogix Chassis is a versatile and reliable platform for industrial automation and control applications. Its high-quality construction, flexible design, and integrated safety features make it an excellent choice for a wide range of applications.

FAQs

Q: What is the maximum number of ControlLogix modules that can be installed in the 1756-A13 chassis?

A: The chassis can accommodate up to 13 ControlLogix modules.

Q: What is the current capacity of the backplane in the 1756-A13 chassis?

A: The backplane current capacity is 10A per slot, or 15A per slot with power supply redundancy.

Q: What power supply options are available for the 1756-A13 chassis?

A: The chassis supports single or redundant power supplies.

Q: What communication options are available for the 1756-A13 chassis?

A: The chassis supports EtherNet/IP, ControlNet, DeviceNet, and other communication modules.

Q: What are the dimensions and weight of the 1756-A13 chassis?

A: The chassis dimensions are 9.05″ H x 17.44″ W x 8.27″ D, and it weighs 8.8 lbs (4.0 kg).

Allen-Bradley 1756-A13 ControlLogix Chassis

Brand: Allen Bradley

Number of slots: 13

Backplane current capacity: 10A per slot, 15A per slot with power supply redundancy

Power supply options: Single or redundant power supplies

Communication options: EtherNet/IP, ControlNet, DeviceNet, and other communication modules

Dimensions: 9.05″ H x 17.44″ W x 8.27″ D

Weight: 8.8 lbs (4.0 kg)l

Product Description

The Allen-Bradley 1756-A13 ControlLogix Chassis is an essential component of the ControlLogix system, providing a sturdy and reliable platform for multiple ControlLogix modules. Here are its features, applications, technical specifications, and benefits.

Features

- 13 slot capacity for ControlLogix modules

- Compact design for easy installation and integration

- High-quality construction for reliable performance

- Integrated safety features for protecting personnel and equipment

- Hot-swappable modules for easy maintenance and upgrades

Applications

- Industrial automation and control systems

- Process control and monitoring

- Material handling and assembly line control

- Robotics and machine control

- Building automation and HVAC control

Technical Specifications

- Number of slots: 13

- Backplane current capacity: 10A per slot, 15A per slot with power supply redundancy

- Power supply options: Single or redundant power supplies

- Communication options: EtherNet/IP, ControlNet, DeviceNet, and other communication modules

- Dimensions: 9.05″ H x 17.44″ W x 8.27″ D

- Weight: 8.8 lbs (4.0 kg)

Benefits

- Flexible and scalable platform for industrial control applications

- High-quality construction ensures reliable and long-lasting performance

- Integrated safety features protect personnel and equipment

- Hot-swappable modules reduce downtime and maintenance costs

- Compact design saves space and simplifies installation and integration

In summary, the Allen-Bradley 1756-A13 ControlLogix Chassis is a versatile and reliable platform for industrial automation and control applications. Its high-quality construction, flexible design, and integrated safety features make it an excellent choice for a wide range of applications.

FAQs

Q: What is the maximum number of ControlLogix modules that can be installed in the 1756-A13 chassis?

A: The chassis can accommodate up to 13 ControlLogix modules.

Q: What is the current capacity of the backplane in the 1756-A13 chassis?

A: The backplane current capacity is 10A per slot, or 15A per slot with power supply redundancy.

Q: What power supply options are available for the 1756-A13 chassis?

A: The chassis supports single or redundant power supplies.

Q: What communication options are available for the 1756-A13 chassis?

A: The chassis supports EtherNet/IP, ControlNet, DeviceNet, and other communication modules.

Q: What are the dimensions and weight of the 1756-A13 chassis?

A: The chassis dimensions are 9.05″ H x 17.44″ W x 8.27″ D, and it weighs 8.8 lbs (4.0 kg).

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...