Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

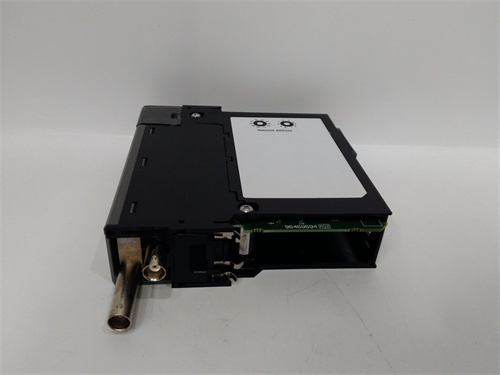

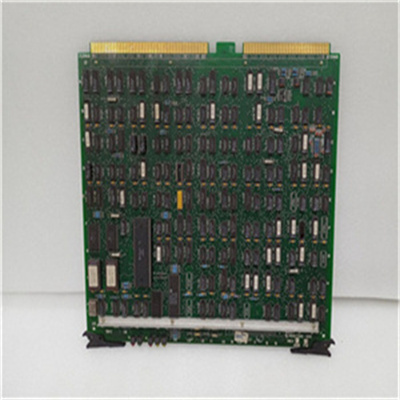

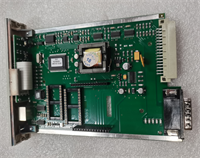

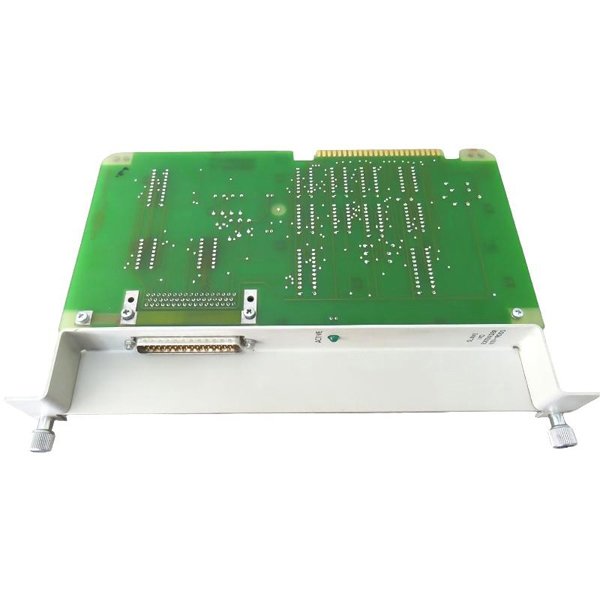

Honeywell 621-9000 Slave I/O Extender Module

Manufacturer:Honeywell

Product Number:621-9000

Product Type:Slave I/O Extender Module

Origin:USA

Dimensions:120 x 35 x 110 mm

Weight:0.23 kg

Views:36

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell 621-9000 Slave I/O Extender Module is a critical part of Honeywell’s PlantScape and TPS (TotalPlant Solution) control architecture. This module enables the extension of local and remote I/O capabilities by acting as a communication and expansion interface between the controller and the connected I/O modules. It allows seamless integration of distributed I/O systems over long distances, supporting complex control strategies without sacrificing performance, reliability, or flexibility.

Designed to operate in demanding industrial environments, the 621-9000 module ensures high-speed data transfer, minimal latency, and robust fault isolation. It is particularly useful in large-scale process automation systems where control elements are dispersed over wide physical areas.

Product Specifications

| Parameter | Details |

|---|---|

| Model | 621-9000 |

| Manufacturer | Honeywell |

| Module Type | Slave I/O Extender Module |

| Function | Slave communication interface for I/O extension |

| Communication Type | Redundant I/O LAN (RS-485-based proprietary protocol) |

| Data Transfer Rate | 1 Mbps (typical) |

| Max Distance (LAN) | Up to 1,500 meters with proper termination |

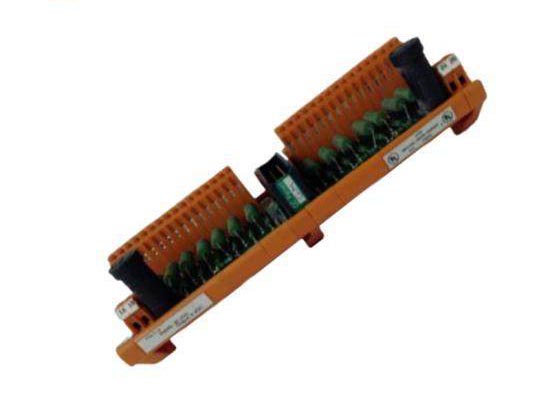

| Connection Type | Terminal block or fiber-optic depending on system |

| Compatibility | Honeywell 620 and 621 I/O systems |

| Power Supply | 5 VDC (from base unit) |

| Isolation | Optical/electrical isolation on communication lines |

| LED Indicators | Status, communication, fault |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% non-condensing |

| Mounting | DIN rail or chassis rack |

| Certifications | CE, UL, CSA |

| Dimensions (H x W x D) | 120 x 35 x 110 mm |

| Weight | 0.23 kg |

Product Applications

The Honeywell 621-9000 module is widely used in industrial automation environments where extended I/O networks are required. It is particularly suitable for:

Refineries & Petrochemical Plants – Enables long-distance signal integration across distributed plant units.

Power Generation Facilities – Connects control modules across different control rooms or turbine floors.

Chemical Processing Plants – Expands digital and analog I/O for complex control sequences.

Pharmaceutical Manufacturing – Links remote instrumentation without introducing noise or latency.

Water Treatment Plants – Connects sensor clusters and actuators spread over large facilities.

Pulp & Paper Industry – Facilitates remote monitoring of process equipment in multi-level buildings.

Product Advantages

Extended I/O Capabilities: Seamlessly expands I/O beyond local limitations without signal degradation.

Robust Communication: Uses a fault-tolerant proprietary RS-485 protocol optimized for industrial use.

System Scalability: Supports large system configurations with multiple I/O racks.

Hot Diagnostics: Real-time diagnostics through LEDs and integrated system alerts.

High Compatibility: Fully integrates with Honeywell 620/621 series, and legacy TPS environments.

Noise Immunity: Optical and electrical isolation ensures clean data transmission in harsh environments.

Minimal Latency: Maintains control responsiveness even with extended communication paths.

FAQ

What communication protocol does the 621-9000 module use?

It uses a proprietary RS-485-based protocol over a redundant I/O LAN for high-integrity communication.

Is the 621-9000 module hot-swappable?

No, power must be turned off before installing or replacing the module to avoid system errors.

Can the module operate in redundant configurations?

Yes, it supports redundant I/O LAN paths for high-availability applications.

Does it require termination resistors?

Yes, proper termination is necessary at the ends of the RS-485 LAN to prevent signal reflection.

Is the module compatible with fiber optic LANs?

Yes, with additional Honeywell transceivers or converters, it can work over fiber-optic media.

What is the maximum number of I/O modules supported through one 621-9000?

This depends on system configuration, but typically supports 31 nodes per segment.

How does the module indicate communication loss?

Through dedicated status and fault LEDs and system diagnostic messages.

Does the module buffer data if LAN communication is interrupted?

No, it does not buffer; real-time communication is required for control updates.

Can multiple 621-9000 modules be used in the same I/O network?

Yes, they are designed to work in multi-module distributed architectures.

What type of electrical isolation is implemented?

Optical isolation is provided on communication interfaces to protect against ground loops and transients.

Honeywell 621-9000 Slave I/O Extender Module

Manufacturer:Honeywell

Product Number:621-9000

Product Type:Slave I/O Extender Module

Origin:USA

Dimensions:120 x 35 x 110 mm

Weight:0.23 kg

Views:36

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell 621-9000 Slave I/O Extender Module is a critical part of Honeywell’s PlantScape and TPS (TotalPlant Solution) control architecture. This module enables the extension of local and remote I/O capabilities by acting as a communication and expansion interface between the controller and the connected I/O modules. It allows seamless integration of distributed I/O systems over long distances, supporting complex control strategies without sacrificing performance, reliability, or flexibility.

Designed to operate in demanding industrial environments, the 621-9000 module ensures high-speed data transfer, minimal latency, and robust fault isolation. It is particularly useful in large-scale process automation systems where control elements are dispersed over wide physical areas.

Product Specifications

| Parameter | Details |

|---|---|

| Model | 621-9000 |

| Manufacturer | Honeywell |

| Module Type | Slave I/O Extender Module |

| Function | Slave communication interface for I/O extension |

| Communication Type | Redundant I/O LAN (RS-485-based proprietary protocol) |

| Data Transfer Rate | 1 Mbps (typical) |

| Max Distance (LAN) | Up to 1,500 meters with proper termination |

| Connection Type | Terminal block or fiber-optic depending on system |

| Compatibility | Honeywell 620 and 621 I/O systems |

| Power Supply | 5 VDC (from base unit) |

| Isolation | Optical/electrical isolation on communication lines |

| LED Indicators | Status, communication, fault |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% non-condensing |

| Mounting | DIN rail or chassis rack |

| Certifications | CE, UL, CSA |

| Dimensions (H x W x D) | 120 x 35 x 110 mm |

| Weight | 0.23 kg |

Product Applications

The Honeywell 621-9000 module is widely used in industrial automation environments where extended I/O networks are required. It is particularly suitable for:

Refineries & Petrochemical Plants – Enables long-distance signal integration across distributed plant units.

Power Generation Facilities – Connects control modules across different control rooms or turbine floors.

Chemical Processing Plants – Expands digital and analog I/O for complex control sequences.

Pharmaceutical Manufacturing – Links remote instrumentation without introducing noise or latency.

Water Treatment Plants – Connects sensor clusters and actuators spread over large facilities.

Pulp & Paper Industry – Facilitates remote monitoring of process equipment in multi-level buildings.

Product Advantages

Extended I/O Capabilities: Seamlessly expands I/O beyond local limitations without signal degradation.

Robust Communication: Uses a fault-tolerant proprietary RS-485 protocol optimized for industrial use.

System Scalability: Supports large system configurations with multiple I/O racks.

Hot Diagnostics: Real-time diagnostics through LEDs and integrated system alerts.

High Compatibility: Fully integrates with Honeywell 620/621 series, and legacy TPS environments.

Noise Immunity: Optical and electrical isolation ensures clean data transmission in harsh environments.

Minimal Latency: Maintains control responsiveness even with extended communication paths.

FAQ

What communication protocol does the 621-9000 module use?

It uses a proprietary RS-485-based protocol over a redundant I/O LAN for high-integrity communication.

Is the 621-9000 module hot-swappable?

No, power must be turned off before installing or replacing the module to avoid system errors.

Can the module operate in redundant configurations?

Yes, it supports redundant I/O LAN paths for high-availability applications.

Does it require termination resistors?

Yes, proper termination is necessary at the ends of the RS-485 LAN to prevent signal reflection.

Is the module compatible with fiber optic LANs?

Yes, with additional Honeywell transceivers or converters, it can work over fiber-optic media.

What is the maximum number of I/O modules supported through one 621-9000?

This depends on system configuration, but typically supports 31 nodes per segment.

How does the module indicate communication loss?

Through dedicated status and fault LEDs and system diagnostic messages.

Does the module buffer data if LAN communication is interrupted?

No, it does not buffer; real-time communication is required for control updates.

Can multiple 621-9000 modules be used in the same I/O network?

Yes, they are designed to work in multi-module distributed architectures.

What type of electrical isolation is implemented?

Optical isolation is provided on communication interfaces to protect against ground loops and transients.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...