Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

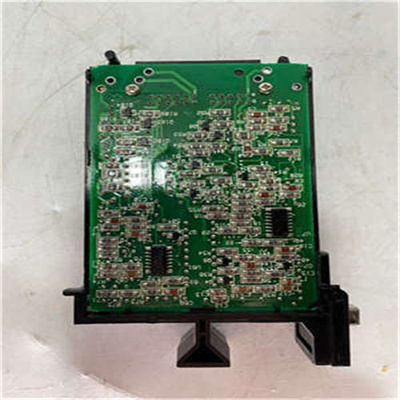

Yokogawa AAI841-S50 PLC Analog I/O Module

Manufacturer:Yokogawa

Product Number: AAI841-S50

Product Type:PLC Analog I/O Module

Origin:Japan

Dimensions:107.5 × 32.8 × 130 mm

Weight :0.3 kg

Views:84

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The module comes equipped with advanced noise filtering, high-speed sampling, and supports redundant communication paths. With HART communication compatibility, it also enables device-level diagnostics and configuration, making it a favored choice in the oil & gas, petrochemical, and power generation sectors.

Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | AAI841-S50 |

| Manufacturer | Yokogawa Electric Corporation |

| Input Type | Analog Input (Current: 4–20 mA DC) |

| Channels | 16 channels |

| HART Support | Supported (channels 1–8) |

| Input Accuracy | ±0.1% of span |

| Isolation | Channel-to-channel and channel-to-ground |

| Resolution | 16-bit A/D conversion |

| Communication Interface | Fieldbus via ESB bus |

| Power Consumption | 3.5 W |

| Operating Temperature | -20 to +70°C |

| Storage Temperature | -40 to +85°C |

| Relative Humidity | 5% to 95% RH (non-condensing) |

| Dimensions | 107.5 × 32.8 × 130 mm |

| Weight | 0.3 kg |

| Mounting | Mounted on baseplate with ESB bus connector |

| Certifications | CE, KC, cUL, ATEX (depending on version) |

Product Applications

The Yokogawa AAI841-S50 module is widely applied in industries where real-time analog data acquisition is critical for control and monitoring. Specific applications include:

Petrochemical refining plants for temperature and pressure monitoring of pipelines.

Oil & Gas offshore platforms, used for wellhead and separator monitoring.

Power generation facilities, especially in boiler control systems.

Water treatment systems for chemical dosing and flow monitoring.

Pharmaceutical manufacturing where precise environmental monitoring is needed.

Pulp and paper production for pressure and level sensing in process tanks.

Its HART functionality further enhances its role in smart field instrument integration.

Product Advantages

High-Density Input: 16 analog input channels in one compact module improve space efficiency.

Integrated HART Communication: Enables advanced diagnostics and digital communication with field devices.

Superior Reliability: Designed for high-availability systems with built-in diagnostic features and redundancy support.

Flexible Configuration: Can be configured per channel, offering scalable control flexibility.

Low Power Consumption: Energy-efficient design allows operation without excessive heat dissipation.

Excellent Noise Rejection: Advanced filtering ensures signal integrity even in electrically noisy environments.

Ease of Maintenance: Hot-swappable design allows replacement without system shutdown.

Certified for Hazardous Areas: Suitable for Zone 2, Class I Div 2 installations.

FAQs

Q1: What types of signals can the AAI841-S50 accept?

A1: It accepts analog current input signals in the range of 4–20 mA DC. HART signals can also be superimposed for compatible channels.

Q2: Is this module hot-swappable?

A2: Yes, it supports hot-swapping when used in combination with appropriate system configuration and redundancy.

Q3: Can I use all 16 channels with HART simultaneously?

A3: No. HART communication is typically supported only on channels 1 to 8, depending on configuration and firmware version.

Q4: What is the isolation provided between channels?

A4: The module provides isolation between individual channels and also from channels to ground, enhancing operational safety.

Q5: What kind of diagnostics does it support?

A5: It supports diagnostics such as wire break detection, open-loop alerts, and HART-based device status feedback.

Q6: Is it compatible with older CENTUM CS3000 systems?

A6: Yes, it is backward compatible with earlier CENTUM versions, though firmware and system integration checks are recommended.

Q7: How does the module handle signal noise?

A7: Through advanced digital filtering algorithms and hardware-level design, it offers strong resistance to electromagnetic and analog noise.

Q8: Can it operate in high-temperature environments?

A8: Yes. The operational range is up to 70°C, making it suitable for most industrial environments.

Q9: What happens during communication failure on one path?

A9: The redundant bus design ensures continued operation via the secondary path without data loss.

Q10: How do I update the firmware or configuration?

A10: Firmware updates and configuration can be performed through the Yokogawa engineering workstation or HART-compatible tools.

Yokogawa AAI841-S50 PLC Analog I/O Module

Manufacturer:Yokogawa

Product Number: AAI841-S50

Product Type:PLC Analog I/O Module

Origin:Japan

Dimensions:107.5 × 32.8 × 130 mm

Weight :0.3 kg

Views:84

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The module comes equipped with advanced noise filtering, high-speed sampling, and supports redundant communication paths. With HART communication compatibility, it also enables device-level diagnostics and configuration, making it a favored choice in the oil & gas, petrochemical, and power generation sectors.

Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | AAI841-S50 |

| Manufacturer | Yokogawa Electric Corporation |

| Input Type | Analog Input (Current: 4–20 mA DC) |

| Channels | 16 channels |

| HART Support | Supported (channels 1–8) |

| Input Accuracy | ±0.1% of span |

| Isolation | Channel-to-channel and channel-to-ground |

| Resolution | 16-bit A/D conversion |

| Communication Interface | Fieldbus via ESB bus |

| Power Consumption | 3.5 W |

| Operating Temperature | -20 to +70°C |

| Storage Temperature | -40 to +85°C |

| Relative Humidity | 5% to 95% RH (non-condensing) |

| Dimensions | 107.5 × 32.8 × 130 mm |

| Weight | 0.3 kg |

| Mounting | Mounted on baseplate with ESB bus connector |

| Certifications | CE, KC, cUL, ATEX (depending on version) |

Product Applications

The Yokogawa AAI841-S50 module is widely applied in industries where real-time analog data acquisition is critical for control and monitoring. Specific applications include:

Petrochemical refining plants for temperature and pressure monitoring of pipelines.

Oil & Gas offshore platforms, used for wellhead and separator monitoring.

Power generation facilities, especially in boiler control systems.

Water treatment systems for chemical dosing and flow monitoring.

Pharmaceutical manufacturing where precise environmental monitoring is needed.

Pulp and paper production for pressure and level sensing in process tanks.

Its HART functionality further enhances its role in smart field instrument integration.

Product Advantages

High-Density Input: 16 analog input channels in one compact module improve space efficiency.

Integrated HART Communication: Enables advanced diagnostics and digital communication with field devices.

Superior Reliability: Designed for high-availability systems with built-in diagnostic features and redundancy support.

Flexible Configuration: Can be configured per channel, offering scalable control flexibility.

Low Power Consumption: Energy-efficient design allows operation without excessive heat dissipation.

Excellent Noise Rejection: Advanced filtering ensures signal integrity even in electrically noisy environments.

Ease of Maintenance: Hot-swappable design allows replacement without system shutdown.

Certified for Hazardous Areas: Suitable for Zone 2, Class I Div 2 installations.

FAQs

Q1: What types of signals can the AAI841-S50 accept?

A1: It accepts analog current input signals in the range of 4–20 mA DC. HART signals can also be superimposed for compatible channels.

Q2: Is this module hot-swappable?

A2: Yes, it supports hot-swapping when used in combination with appropriate system configuration and redundancy.

Q3: Can I use all 16 channels with HART simultaneously?

A3: No. HART communication is typically supported only on channels 1 to 8, depending on configuration and firmware version.

Q4: What is the isolation provided between channels?

A4: The module provides isolation between individual channels and also from channels to ground, enhancing operational safety.

Q5: What kind of diagnostics does it support?

A5: It supports diagnostics such as wire break detection, open-loop alerts, and HART-based device status feedback.

Q6: Is it compatible with older CENTUM CS3000 systems?

A6: Yes, it is backward compatible with earlier CENTUM versions, though firmware and system integration checks are recommended.

Q7: How does the module handle signal noise?

A7: Through advanced digital filtering algorithms and hardware-level design, it offers strong resistance to electromagnetic and analog noise.

Q8: Can it operate in high-temperature environments?

A8: Yes. The operational range is up to 70°C, making it suitable for most industrial environments.

Q9: What happens during communication failure on one path?

A9: The redundant bus design ensures continued operation via the secondary path without data loss.

Q10: How do I update the firmware or configuration?

A10: Firmware updates and configuration can be performed through the Yokogawa engineering workstation or HART-compatible tools.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...