Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

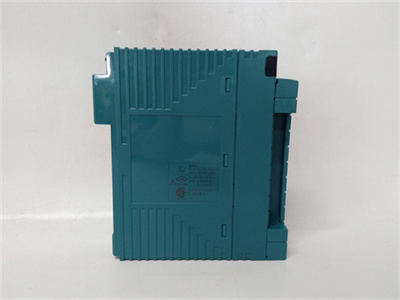

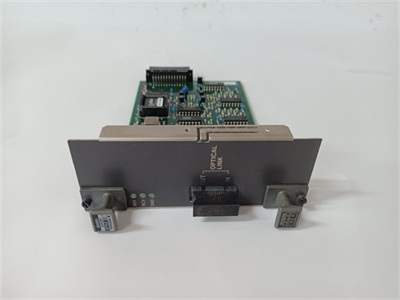

Yokogawa SSC50D-S2111 Duplexed Safety Control Unit

Manufacturer:Yokogawa

Product Number:SSC50D-S2111

Product Type:Duplexed Safety Control Unit

Origin:Japan

Dimensions:482.6 x 266 x 88.1 mm

Weight :8.5 kg

Views:9

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa SSC50D-S2111 Duplexed Safety Control Unit is an advanced safety controller designed for high-reliability applications in industrial automation and process safety systems. Built with duplexed (redundant) architecture, it ensures continuous and fail-safe operation, even under fault conditions. This unit plays a critical role in Safety Instrumented Systems (SIS), meeting stringent international safety standards for industries such as oil & gas, petrochemical, power generation, and chemical processing.

The SSC50D-S2111 integrates with Yokogawa’s ProSafe-RS safety control platform and provides superior diagnostic capabilities, high processing performance, and a modular structure for flexible expansion.

Technical Specifications

| Parameter | Description |

|---|---|

| Model | SSC50D-S2111 Duplexed Safety Control Unit |

| Architecture | Duplexed (redundant) safety CPU |

| System Type | ProSafe-RS Safety Control |

| Processor | High-performance 32-bit RISC processors |

| Safety Standards | IEC 61508 SIL3, IEC 61511 compliance |

| Power Supply | 24 V DC nominal (redundant supported) |

| Input/Output Support | Compatible with safety I/O modules (DI, DO, AI, AO) |

| Communication | Vnet/IP, Safety communication with field devices |

| Diagnostic Functions | Online self-diagnostics, fault isolation, redundancy monitoring |

| Operating Temperature | 0 to 55 °C |

| Humidity | 10% to 90% non-condensing |

| Dimensions | 482.6 x 266 x 88.1 mm |

| Weight | 8.5 kg |

Product Applications

Safety Instrumented Systems (SIS): Ensures safe shutdown and emergency control in refineries, chemical plants, and offshore platforms.

Emergency Shutdown (ESD): Provides fast and reliable trip functionality during hazardous conditions.

Fire & Gas Systems: Supports integration with flame, smoke, and gas detection systems for safe operation.

Turbomachinery Safety: Used for critical rotating machinery protection in power plants and oil & gas facilities.

Process Interlock Systems: Guarantees interlock logic enforcement to prevent unsafe process conditions.

High-Reliability Control: Suitable for applications requiring high availability and minimal downtime.

Product Advantages

Duplex Redundancy: Provides fault tolerance with automatic switchover for uninterrupted operation.

SIL3 Certified: Complies with IEC safety standards, making it suitable for high-integrity safety applications.

High Reliability: Online diagnostics and error detection ensure system integrity.

Seamless Integration: Works natively with Yokogawa’s CENTUM VP and ProSafe-RS systems.

Scalable Architecture: Supports expansion with additional safety I/O modules.

Reduced Downtime: Hot-swap capability and redundant modules minimize operational interruptions.

Proven Field Experience: Widely adopted in global industries with strong reliability record.

FAQ

Q1: What safety standard certifications does the SSC50D-S2111 comply with?

A1: It is certified to IEC 61508 SIL3 and complies with IEC 61511 for process safety applications.

Q2: How does the duplexed architecture enhance system reliability?

A2: Duplexed architecture provides two redundant CPUs that run in parallel, ensuring that if one fails, the other continues operation without process interruption.

Q3: Can the SSC50D-S2111 be integrated with non-Yokogawa systems?

A3: Yes, it supports standard communication protocols such as Vnet/IP and safety communication, allowing integration with third-party systems.

Q4: What diagnostic features are included in the SSC50D-S2111?

A4: It includes continuous self-diagnostics, redundancy monitoring, communication integrity checks, and fault isolation features.

Q5: Does this unit support hot-swapping of modules?

A5: Yes, it supports hot-swapping of I/O modules and redundant components, minimizing downtime during maintenance.

Q6: How does the SSC50D-S2111 ensure compliance with SIL3 requirements?

A6: It uses hardware redundancy, diverse diagnostics, and proven safety algorithms to meet SIL3 certification standards.

Q7: What communication backbone does the SSC50D-S2111 utilize?

A7: It uses Yokogawa’s Vnet/IP high-speed network for secure and reliable communication.

Q8: Can the SSC50D-S2111 handle both safety and control functions simultaneously?

A8: No, it is dedicated to safety functions and operates separately from the process control system to meet safety integrity standards.

Q9: How is redundancy handled between the duplex CPUs?

A9: Both CPUs execute the same logic in parallel, and a comparison mechanism ensures consistent operation. If a mismatch occurs, the healthy CPU continues seamlessly.

Q10: What type of I/O modules are compatible with the SSC50D-S2111?

A10: It is compatible with ProSafe-RS safety I/O modules, including digital input/output and analog input/output types.

Yokogawa SSC50D-S2111 Duplexed Safety Control Unit

Manufacturer:Yokogawa

Product Number:SSC50D-S2111

Product Type:Duplexed Safety Control Unit

Origin:Japan

Dimensions:482.6 x 266 x 88.1 mm

Weight :8.5 kg

Views:9

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa SSC50D-S2111 Duplexed Safety Control Unit is an advanced safety controller designed for high-reliability applications in industrial automation and process safety systems. Built with duplexed (redundant) architecture, it ensures continuous and fail-safe operation, even under fault conditions. This unit plays a critical role in Safety Instrumented Systems (SIS), meeting stringent international safety standards for industries such as oil & gas, petrochemical, power generation, and chemical processing.

The SSC50D-S2111 integrates with Yokogawa’s ProSafe-RS safety control platform and provides superior diagnostic capabilities, high processing performance, and a modular structure for flexible expansion.

Technical Specifications

| Parameter | Description |

|---|---|

| Model | SSC50D-S2111 Duplexed Safety Control Unit |

| Architecture | Duplexed (redundant) safety CPU |

| System Type | ProSafe-RS Safety Control |

| Processor | High-performance 32-bit RISC processors |

| Safety Standards | IEC 61508 SIL3, IEC 61511 compliance |

| Power Supply | 24 V DC nominal (redundant supported) |

| Input/Output Support | Compatible with safety I/O modules (DI, DO, AI, AO) |

| Communication | Vnet/IP, Safety communication with field devices |

| Diagnostic Functions | Online self-diagnostics, fault isolation, redundancy monitoring |

| Operating Temperature | 0 to 55 °C |

| Humidity | 10% to 90% non-condensing |

| Dimensions | 482.6 x 266 x 88.1 mm |

| Weight | 8.5 kg |

Product Applications

Safety Instrumented Systems (SIS): Ensures safe shutdown and emergency control in refineries, chemical plants, and offshore platforms.

Emergency Shutdown (ESD): Provides fast and reliable trip functionality during hazardous conditions.

Fire & Gas Systems: Supports integration with flame, smoke, and gas detection systems for safe operation.

Turbomachinery Safety: Used for critical rotating machinery protection in power plants and oil & gas facilities.

Process Interlock Systems: Guarantees interlock logic enforcement to prevent unsafe process conditions.

High-Reliability Control: Suitable for applications requiring high availability and minimal downtime.

Product Advantages

Duplex Redundancy: Provides fault tolerance with automatic switchover for uninterrupted operation.

SIL3 Certified: Complies with IEC safety standards, making it suitable for high-integrity safety applications.

High Reliability: Online diagnostics and error detection ensure system integrity.

Seamless Integration: Works natively with Yokogawa’s CENTUM VP and ProSafe-RS systems.

Scalable Architecture: Supports expansion with additional safety I/O modules.

Reduced Downtime: Hot-swap capability and redundant modules minimize operational interruptions.

Proven Field Experience: Widely adopted in global industries with strong reliability record.

FAQ

Q1: What safety standard certifications does the SSC50D-S2111 comply with?

A1: It is certified to IEC 61508 SIL3 and complies with IEC 61511 for process safety applications.

Q2: How does the duplexed architecture enhance system reliability?

A2: Duplexed architecture provides two redundant CPUs that run in parallel, ensuring that if one fails, the other continues operation without process interruption.

Q3: Can the SSC50D-S2111 be integrated with non-Yokogawa systems?

A3: Yes, it supports standard communication protocols such as Vnet/IP and safety communication, allowing integration with third-party systems.

Q4: What diagnostic features are included in the SSC50D-S2111?

A4: It includes continuous self-diagnostics, redundancy monitoring, communication integrity checks, and fault isolation features.

Q5: Does this unit support hot-swapping of modules?

A5: Yes, it supports hot-swapping of I/O modules and redundant components, minimizing downtime during maintenance.

Q6: How does the SSC50D-S2111 ensure compliance with SIL3 requirements?

A6: It uses hardware redundancy, diverse diagnostics, and proven safety algorithms to meet SIL3 certification standards.

Q7: What communication backbone does the SSC50D-S2111 utilize?

A7: It uses Yokogawa’s Vnet/IP high-speed network for secure and reliable communication.

Q8: Can the SSC50D-S2111 handle both safety and control functions simultaneously?

A8: No, it is dedicated to safety functions and operates separately from the process control system to meet safety integrity standards.

Q9: How is redundancy handled between the duplex CPUs?

A9: Both CPUs execute the same logic in parallel, and a comparison mechanism ensures consistent operation. If a mismatch occurs, the healthy CPU continues seamlessly.

Q10: What type of I/O modules are compatible with the SSC50D-S2111?

A10: It is compatible with ProSafe-RS safety I/O modules, including digital input/output and analog input/output types.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...