Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

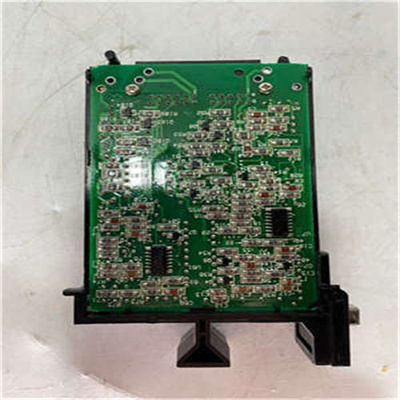

Yokogawa F3RZ91-0F Ladder Diagram Communication Module

Manufacturer:Yokogawa

Product Number:F3RZ91-0F

Product Type:Ladder Diagram Communication Module

Origin:Japan

Dimensions:28.9 × 100 × 83.2 mm

Weight:0.12kg

Views:18

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa F3RZ91-0F Ladder Diagram Communication Module is designed for CENTUM VP distributed control systems to enable seamless communication between ladder logic programs and system controllers. It provides reliable data exchange for control sequences, facilitating real-time monitoring and operational flexibility.

Key Features

Enables ladder logic program communication within CENTUM VP systems

Real-time data exchange with system controllers and field devices

Simplifies integration of ladder logic modules into the control system

Reliable operation under demanding industrial conditions

Supports system expansion and flexible control strategies

Status monitoring via onboard LEDs

Technical Specifications

| Item | Specification |

|---|---|

| Model Number | F3RZ91-0F |

| Module Type | Ladder Diagram Communication Module |

| System Compatibility | Yokogawa CENTUM VP |

| Communication Interface | Digital communication with controllers |

| Communication Speed | System dependent |

| Operating Temperature | 0 °C to 55 °C |

| Storage Temperature | -20 °C to 70 °C |

| Humidity | 10% to 90% RH (non-condensing) |

| Dimensions | 28.9 × 100 × 83.2 mm |

| Weight | 0.32 kg |

| Mounting | DIN-rail or panel mounting |

| Indicators | Status LEDs for communication and module operation |

Industry Applications

Oil & Gas – Communication interface for control sequences in field devices

Power Generation – Integration of ladder logic for turbines and generators

Chemical & Petrochemical – Real-time ladder logic control for process equipment

Water & Wastewater – Monitoring and control of pumps and sensors

Pharmaceutical & Food Processing – Reliable ladder logic integration for automation

Advantages

-

Facilitates efficient ladder logic communication within CENTUM VP systems

-

Supports integration of additional ladder modules and system expansion

-

Enables real-time monitoring and control

-

Simplifies network management and maintenance

-

Designed for reliable industrial operation

Frequently Asked Questions (FAQ)

Q1: What is the primary function of the F3RZ91-0F module?

It enables ladder logic program communication with CENTUM VP controllers.

Q2: Which systems is it compatible with?

It is compatible with Yokogawa CENTUM VP systems.

Q3: What type of communication interface does it support?

Digital communication with system controllers and field devices.

Q4: What is the operating temperature range?

0 °C to 55 °C.

Q5: How is the module mounted?

It can be mounted on DIN-rails or control panels.

Q6: What indicators are included?

Status LEDs indicate communication status and module operation.

Q7: Can it handle real-time communication?

Yes, it supports system-dependent real-time data exchange.

Q8: Is it suitable for harsh industrial environments?

Yes, it is designed for reliable operation under industrial conditions.

Q9: What are the module dimensions?

28.9 mm × 100 mm × 83.2 mm.

Q10: How much does the module weigh?

Approximately 0.12 kg.

Yokogawa F3RZ91-0F Ladder Diagram Communication Module

Manufacturer:Yokogawa

Product Number:F3RZ91-0F

Product Type:Ladder Diagram Communication Module

Origin:Japan

Dimensions:28.9 × 100 × 83.2 mm

Weight:0.12kg

Views:18

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa F3RZ91-0F Ladder Diagram Communication Module is designed for CENTUM VP distributed control systems to enable seamless communication between ladder logic programs and system controllers. It provides reliable data exchange for control sequences, facilitating real-time monitoring and operational flexibility.

Key Features

Enables ladder logic program communication within CENTUM VP systems

Real-time data exchange with system controllers and field devices

Simplifies integration of ladder logic modules into the control system

Reliable operation under demanding industrial conditions

Supports system expansion and flexible control strategies

Status monitoring via onboard LEDs

Technical Specifications

| Item | Specification |

|---|---|

| Model Number | F3RZ91-0F |

| Module Type | Ladder Diagram Communication Module |

| System Compatibility | Yokogawa CENTUM VP |

| Communication Interface | Digital communication with controllers |

| Communication Speed | System dependent |

| Operating Temperature | 0 °C to 55 °C |

| Storage Temperature | -20 °C to 70 °C |

| Humidity | 10% to 90% RH (non-condensing) |

| Dimensions | 28.9 × 100 × 83.2 mm |

| Weight | 0.32 kg |

| Mounting | DIN-rail or panel mounting |

| Indicators | Status LEDs for communication and module operation |

Industry Applications

Oil & Gas – Communication interface for control sequences in field devices

Power Generation – Integration of ladder logic for turbines and generators

Chemical & Petrochemical – Real-time ladder logic control for process equipment

Water & Wastewater – Monitoring and control of pumps and sensors

Pharmaceutical & Food Processing – Reliable ladder logic integration for automation

Advantages

-

Facilitates efficient ladder logic communication within CENTUM VP systems

-

Supports integration of additional ladder modules and system expansion

-

Enables real-time monitoring and control

-

Simplifies network management and maintenance

-

Designed for reliable industrial operation

Frequently Asked Questions (FAQ)

Q1: What is the primary function of the F3RZ91-0F module?

It enables ladder logic program communication with CENTUM VP controllers.

Q2: Which systems is it compatible with?

It is compatible with Yokogawa CENTUM VP systems.

Q3: What type of communication interface does it support?

Digital communication with system controllers and field devices.

Q4: What is the operating temperature range?

0 °C to 55 °C.

Q5: How is the module mounted?

It can be mounted on DIN-rails or control panels.

Q6: What indicators are included?

Status LEDs indicate communication status and module operation.

Q7: Can it handle real-time communication?

Yes, it supports system-dependent real-time data exchange.

Q8: Is it suitable for harsh industrial environments?

Yes, it is designed for reliable operation under industrial conditions.

Q9: What are the module dimensions?

28.9 mm × 100 mm × 83.2 mm.

Q10: How much does the module weigh?

Approximately 0.12 kg.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...