Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

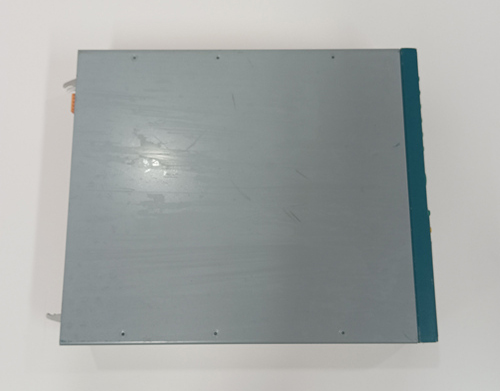

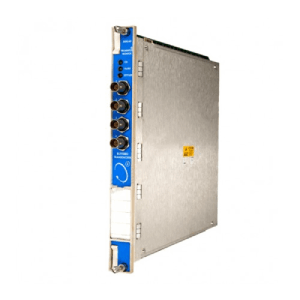

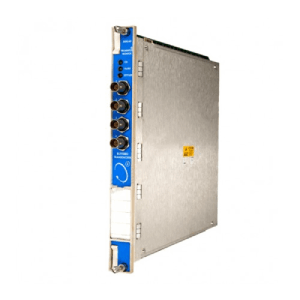

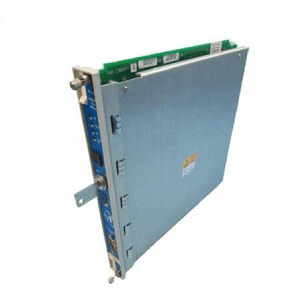

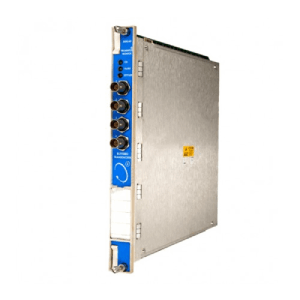

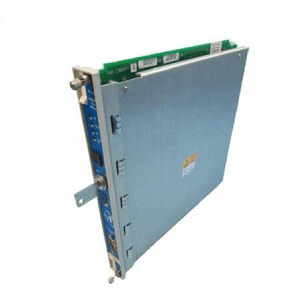

Bently Nevada 3500/72M Recip Rod Position Monitor

Part Number: 3500/72-01-01

Model: Recip Rod Position Monitor

Brand: Bently Nevada

Condition: New & Original in Factory Packing

Factory Warranty: 12 Months

Shipping Weight: 2 Kg

Model: 3500/72 Recip Rod Position Monitor

I/O Module Type: 01 I/O Module with Internal Terminations

Agency Approval Option: 01 CSA/NRTL/C

Made in : U.S.A

Shipping Port:China

Lead Time:1-3 Days

Condition:Brand New And Original

Warranty:365 Days

Certificate:COO

Product Description

The Bently Nevada 3500/72M Recip Rod Position Monitor is a four-channel device designed to monitor reciprocating compressors. The monitor accepts input from proximity transducers, conditions the signal to provide dynamic and static position measurements, and compares the conditioned signals with user-programmable alarms. With this monitor, you can configure alert setpoints for each active measured value and danger setpoints for any two of the active measured values.

The 3500/72M Recip Rod Position Monitor is an essential tool for reciprocating compressor machinery. It is designed to protect the compressor by continuously comparing monitored parameters against configured alarm setpoints to display alarms and trigger relays if needed. This monitor is programmed using the 3500 Rack Configuration Software, which allows you to monitor the condition of the machinery and provide information for both operations and maintenance personnel.

Channel Configuration and Functions

The monitor channels are programmed in pairs and can perform up to two functions at a time. For example, channels 1 and 2 can perform one function while channels 3 and 4 perform another or the same function. Each channel, depending on how you configure it, typically conditions its input signal to generate various parameters called measured values. These measured values include rod position, rod drop, and hyper-compressor.

API 618 Requirements

The 3500/72M Recip Rod Position Monitor meets API 618 requirements for reciprocating compressors. API 618 is a specification for designing, manufacturing, and testing reciprocating compressors. It is intended to ensure that compressors are designed, manufactured, and tested to meet specific performance and safety standards. Compliance with API 618 is essential to ensure the safe and efficient operation of reciprocating compressors. The 3500/72M Recip Rod Position Monitor is designed to meet these requirements and provides reliable monitoring and protection for reciprocating compressors.

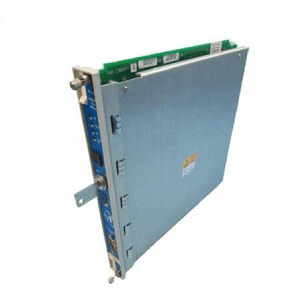

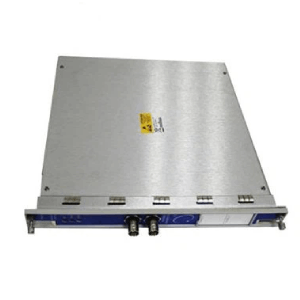

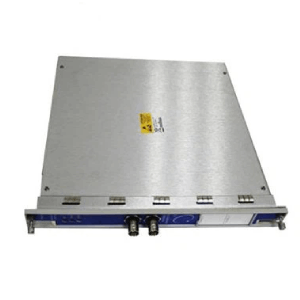

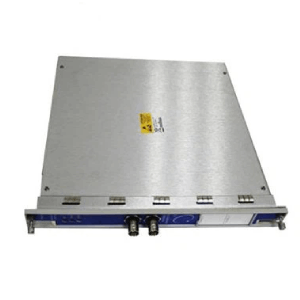

Physical of Bently Nevada 3500/72M-01-00 module Recip Rod Position Monitor 3500/72M-01-00

| Monitor Module (Main Board) | |

|

Dimensions

(Height x Width x Depth) |

241.3 mm x 24.4 mm x 241.8 mm

(9.50 in x 0.96 in x 9.52 in) |

| Weight | 0.91 kg (2.0 lb) |

| I/O Modules (non-barrier) | |

|

Dimensions

(Height x Width x Depth) |

241.3 mm x 24.4 mm x 99.1 mm

(9.50 in x 0.96 in x 3.90 in) |

| Weight | 0.20 kg (0.44 lb) |

| I/O Modules (barrier) | |

|

Dimensions

(Height x Width x Depth) |

241.3 mm x 24.4 mm x 163.1 mm

(9.50 in x 0.96 in x 6.42 in) |

| Weight | 0.46 kg (1.01 lb) |

Bently Nevada 3500/72M Recip Rod Position Monitor

Part Number: 3500/72-01-01

Model: Recip Rod Position Monitor

Brand: Bently Nevada

Condition: New & Original in Factory Packing

Factory Warranty: 12 Months

Shipping Weight: 2 Kg

Model: 3500/72 Recip Rod Position Monitor

I/O Module Type: 01 I/O Module with Internal Terminations

Agency Approval Option: 01 CSA/NRTL/C

Made in : U.S.A

Shipping Port:China

Lead Time:1-3 Days

Condition:Brand New And Original

Warranty:365 Days

Certificate:COO

Product Description

The Bently Nevada 3500/72M Recip Rod Position Monitor is a four-channel device designed to monitor reciprocating compressors. The monitor accepts input from proximity transducers, conditions the signal to provide dynamic and static position measurements, and compares the conditioned signals with user-programmable alarms. With this monitor, you can configure alert setpoints for each active measured value and danger setpoints for any two of the active measured values.

The 3500/72M Recip Rod Position Monitor is an essential tool for reciprocating compressor machinery. It is designed to protect the compressor by continuously comparing monitored parameters against configured alarm setpoints to display alarms and trigger relays if needed. This monitor is programmed using the 3500 Rack Configuration Software, which allows you to monitor the condition of the machinery and provide information for both operations and maintenance personnel.

Channel Configuration and Functions

The monitor channels are programmed in pairs and can perform up to two functions at a time. For example, channels 1 and 2 can perform one function while channels 3 and 4 perform another or the same function. Each channel, depending on how you configure it, typically conditions its input signal to generate various parameters called measured values. These measured values include rod position, rod drop, and hyper-compressor.

API 618 Requirements

The 3500/72M Recip Rod Position Monitor meets API 618 requirements for reciprocating compressors. API 618 is a specification for designing, manufacturing, and testing reciprocating compressors. It is intended to ensure that compressors are designed, manufactured, and tested to meet specific performance and safety standards. Compliance with API 618 is essential to ensure the safe and efficient operation of reciprocating compressors. The 3500/72M Recip Rod Position Monitor is designed to meet these requirements and provides reliable monitoring and protection for reciprocating compressors.

Physical of Bently Nevada 3500/72M-01-00 module Recip Rod Position Monitor 3500/72M-01-00

| Monitor Module (Main Board) | |

|

Dimensions

(Height x Width x Depth) |

241.3 mm x 24.4 mm x 241.8 mm

(9.50 in x 0.96 in x 9.52 in) |

| Weight | 0.91 kg (2.0 lb) |

| I/O Modules (non-barrier) | |

|

Dimensions

(Height x Width x Depth) |

241.3 mm x 24.4 mm x 99.1 mm

(9.50 in x 0.96 in x 3.90 in) |

| Weight | 0.20 kg (0.44 lb) |

| I/O Modules (barrier) | |

|

Dimensions

(Height x Width x Depth) |

241.3 mm x 24.4 mm x 163.1 mm

(9.50 in x 0.96 in x 6.42 in) |

| Weight | 0.46 kg (1.01 lb) |

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...