Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

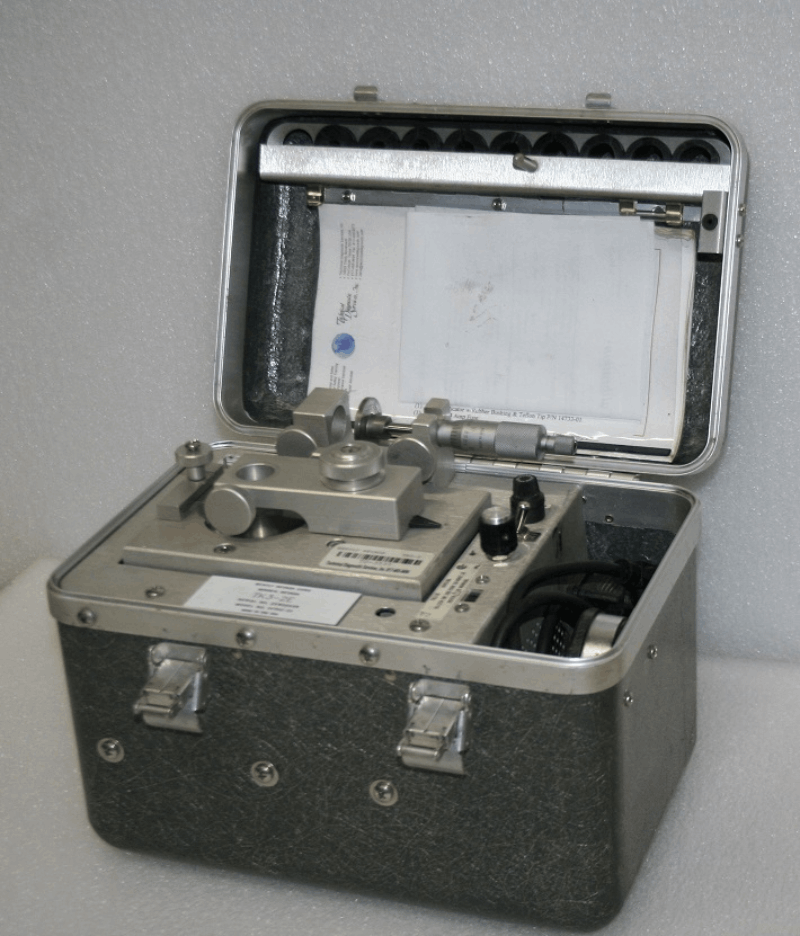

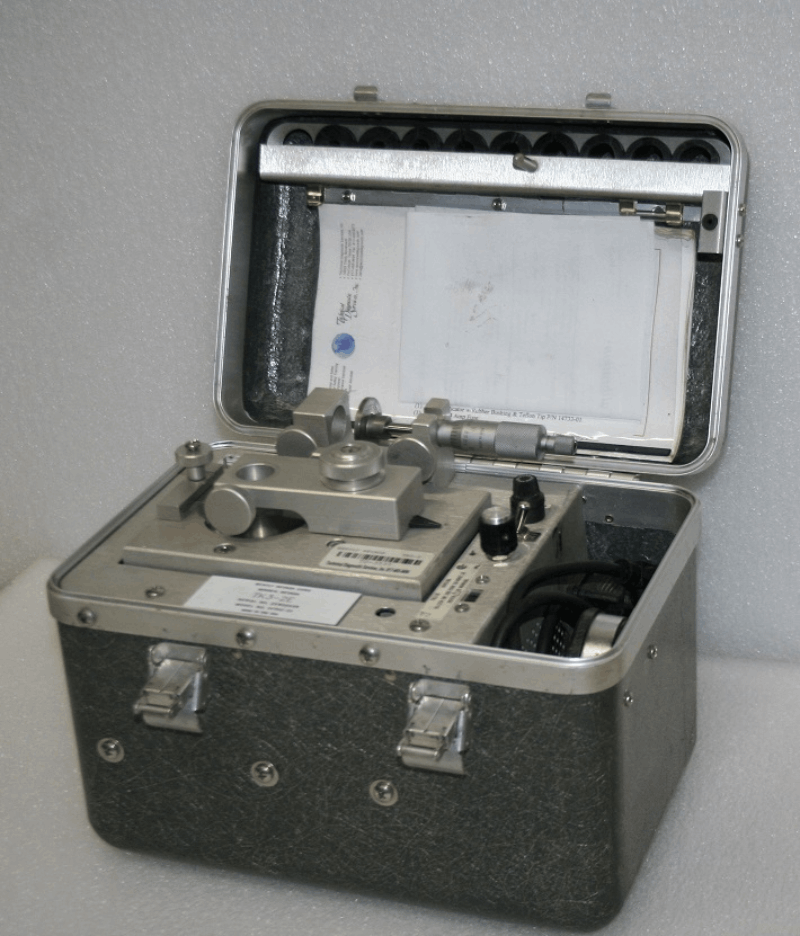

Bently Nevada TK3-2E Proximity Probe Test System

Brand: Bently Nevada

Model Number: TK3-2E

Type: Proximity Probe Test System

Product Origin: USA

Payment: T/T, Western Union, Credit Card

Dimensions: 300 x 200 x 100 mm

Weight: 5 kg

Certificate: ISO 9001:2015

Warranty: 1 year

Product Description

The Bently Nevada TK3-2E is a portable proximity probe test system that simulates shaft vibration and position for calibrating proximity probes. It is used by industrial automation R&D engineers to ensure the accuracy of their proximity probes, which are used to monitor the condition of rotating machinery.

The system uses advanced signal processing algorithms to analyze vibration data and detect potential problems before they become critical. The system can detect a wide range of faults, including bearing wear, misalignment, imbalance, and looseness. The system can also detect changes in the operating conditions of the machine, such as changes in load or speed.

The TK3-2E system is easy to install and configure, with a user-friendly interface that allows operators to set up the system quickly and easily. The system can be configured to provide alarms and alerts when problems are detected, allowing operators to take corrective action before equipment failure occurs.

Overall, the Bently Nevada TK3-2E Vibration Monitoring System is a powerful tool for machine protection and condition monitoring. It provides operators and maintenance personnel with real-time data on the performance of rotating machinery, allowing them to optimize machine performance and prevent equipment failures.

The Bently Nevada TK3-2E Vibration Monitoring System is a high-performance vibration monitoring system designed for use in industrial and commercial applications. Some of the key product features of this system include:

- High Accuracy: The TK3-2E system is highly accurate, providing reliable vibration monitoring data to help detect potential issues before they become critical.

- Easy to Use: The system is designed to be easy to use, with intuitive controls and a user-friendly interface.

- Versatile: The TK3-2E system can be used in a wide range of applications, from monitoring large industrial machinery to smaller commercial equipment.

- Robust: The system is built to withstand harsh industrial environments, and is designed to operate reliably even in extreme conditions.

- Scalable: The TK3-2E system is scalable, allowing users to easily expand the system as their needs grow.

- Advanced Diagnostics: The system includes advanced diagnostic capabilities, allowing users to quickly identify and troubleshoot issues.

- Remote Monitoring: The TK3-2E system includes remote monitoring capabilities, allowing users to monitor equipment from a distance and receive alerts when issues arise.

Overall, the Bently Nevada TK3-2E Vibration Monitoring System is a powerful and versatile tool for monitoring vibration in industrial and commercial applications, providing users with the data they need to keep their equipment running smoothly and efficiently.

Q: What is the Bently Nevada TK3-2E Vibration Monitoring System?

A: The Bently Nevada TK3-2E Vibration Monitoring System is a machine monitoring system designed to provide continuous vibration monitoring and analysis for rotating machinery. It is capable of detecting potential machinery problems and alerting operators before they become critical failures.

Q: What types of machinery can the TK3-2E monitor?

A: The TK3-2E can monitor a wide range of rotating machinery, including pumps, compressors, turbines, motors, and generators.

Q: What are the key features of the TK3-2E?

A: The TK3-2E features advanced vibration analysis capabilities, including spectrum analysis and waveform analysis. It also includes a user-friendly interface and customizable alarm settings.

Q: How does the TK3-2E work?

A: The TK3-2E uses accelerometers to measure vibration levels on the machinery being monitored. This data is then analyzed by the system to detect potential problems and alert operators.

Q: What are the benefits of using the TK3-2E?

A: The TK3-2E can help reduce downtime and maintenance costs by detecting potential machinery problems before they become critical failures. It can also improve overall equipment reliability and extend the life of machinery.

Q: What is spectrum analysis?

A: Spectrum analysis is a technique used in vibration analysis to break down the vibration signal into its individual frequency components. This allows operators to identify the specific frequencies that are causing the vibration and determine the root cause of the problem.

Q: What is waveform analysis?

A: Waveform analysis is a technique used in vibration analysis to analyze the shape and characteristics of the vibration signal. This can help operators identify specific types of vibration, such as bearing faults or misalignment.

Q: How customizable are the alarm settings on the TK3-2E?

A: The TK3-2E includes a variety of customizable alarm settings, including alarm thresholds, alarm delays, and alarm priority levels. This allows operators to tailor the system to meet their specific needs and requirements.

Q: What types of accelerometers can be used with the TK3-2E?

A: The TK3-2E is compatible with a wide range of accelerometers, including both piezoelectric and piezoresistive types.

Q: Is the TK3-2E suitable for use in hazardous environments?

A: Yes, the TK3-2E is designed for use in hazardous environments and is certified for use in Class I, Division 2, Groups A, B, C, and D environments.

Bently Nevada TK3-2E Proximity Probe Test System

Brand: Bently Nevada

Model Number: TK3-2E

Type: Proximity Probe Test System

Product Origin: USA

Payment: T/T, Western Union, Credit Card

Dimensions: 300 x 200 x 100 mm

Weight: 5 kg

Certificate: ISO 9001:2015

Warranty: 1 year

Product Description

The Bently Nevada TK3-2E is a portable proximity probe test system that simulates shaft vibration and position for calibrating proximity probes. It is used by industrial automation R&D engineers to ensure the accuracy of their proximity probes, which are used to monitor the condition of rotating machinery.

The system uses advanced signal processing algorithms to analyze vibration data and detect potential problems before they become critical. The system can detect a wide range of faults, including bearing wear, misalignment, imbalance, and looseness. The system can also detect changes in the operating conditions of the machine, such as changes in load or speed.

The TK3-2E system is easy to install and configure, with a user-friendly interface that allows operators to set up the system quickly and easily. The system can be configured to provide alarms and alerts when problems are detected, allowing operators to take corrective action before equipment failure occurs.

Overall, the Bently Nevada TK3-2E Vibration Monitoring System is a powerful tool for machine protection and condition monitoring. It provides operators and maintenance personnel with real-time data on the performance of rotating machinery, allowing them to optimize machine performance and prevent equipment failures.

The Bently Nevada TK3-2E Vibration Monitoring System is a high-performance vibration monitoring system designed for use in industrial and commercial applications. Some of the key product features of this system include:

- High Accuracy: The TK3-2E system is highly accurate, providing reliable vibration monitoring data to help detect potential issues before they become critical.

- Easy to Use: The system is designed to be easy to use, with intuitive controls and a user-friendly interface.

- Versatile: The TK3-2E system can be used in a wide range of applications, from monitoring large industrial machinery to smaller commercial equipment.

- Robust: The system is built to withstand harsh industrial environments, and is designed to operate reliably even in extreme conditions.

- Scalable: The TK3-2E system is scalable, allowing users to easily expand the system as their needs grow.

- Advanced Diagnostics: The system includes advanced diagnostic capabilities, allowing users to quickly identify and troubleshoot issues.

- Remote Monitoring: The TK3-2E system includes remote monitoring capabilities, allowing users to monitor equipment from a distance and receive alerts when issues arise.

Overall, the Bently Nevada TK3-2E Vibration Monitoring System is a powerful and versatile tool for monitoring vibration in industrial and commercial applications, providing users with the data they need to keep their equipment running smoothly and efficiently.

Q: What is the Bently Nevada TK3-2E Vibration Monitoring System?

A: The Bently Nevada TK3-2E Vibration Monitoring System is a machine monitoring system designed to provide continuous vibration monitoring and analysis for rotating machinery. It is capable of detecting potential machinery problems and alerting operators before they become critical failures.

Q: What types of machinery can the TK3-2E monitor?

A: The TK3-2E can monitor a wide range of rotating machinery, including pumps, compressors, turbines, motors, and generators.

Q: What are the key features of the TK3-2E?

A: The TK3-2E features advanced vibration analysis capabilities, including spectrum analysis and waveform analysis. It also includes a user-friendly interface and customizable alarm settings.

Q: How does the TK3-2E work?

A: The TK3-2E uses accelerometers to measure vibration levels on the machinery being monitored. This data is then analyzed by the system to detect potential problems and alert operators.

Q: What are the benefits of using the TK3-2E?

A: The TK3-2E can help reduce downtime and maintenance costs by detecting potential machinery problems before they become critical failures. It can also improve overall equipment reliability and extend the life of machinery.

Q: What is spectrum analysis?

A: Spectrum analysis is a technique used in vibration analysis to break down the vibration signal into its individual frequency components. This allows operators to identify the specific frequencies that are causing the vibration and determine the root cause of the problem.

Q: What is waveform analysis?

A: Waveform analysis is a technique used in vibration analysis to analyze the shape and characteristics of the vibration signal. This can help operators identify specific types of vibration, such as bearing faults or misalignment.

Q: How customizable are the alarm settings on the TK3-2E?

A: The TK3-2E includes a variety of customizable alarm settings, including alarm thresholds, alarm delays, and alarm priority levels. This allows operators to tailor the system to meet their specific needs and requirements.

Q: What types of accelerometers can be used with the TK3-2E?

A: The TK3-2E is compatible with a wide range of accelerometers, including both piezoelectric and piezoresistive types.

Q: Is the TK3-2E suitable for use in hazardous environments?

A: Yes, the TK3-2E is designed for use in hazardous environments and is certified for use in Class I, Division 2, Groups A, B, C, and D environments.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...