BENTLY 3500/22M Product Introduction

BENTLY 3500/22M is a transient data interface module developed by Bently Nevada,which belongs to Bently’s monitoring and control system product line.The module is designed to connect various sensors and devices to collect,store and process transient and steady-state data,and pass these data to the host software for further analysis and processing.

Product Features

High-performance processor and memory

BENTLY 3500/22M is equipped with a more powerful processor and memory,which can handle more data and more complex control algorithms,thereby improving control accuracy and response speed.

Rich communication interfaces

The module supports a variety of different communication interfaces,such as Ethernet,serial port,CAN bus,etc.,which can easily communicate and control with various devices.

Flexible programming

BENTLY 3500/22M supports multiple programming languages,such as C/C++,LabVIEW,etc.,which is convenient for users to carry out secondary development and customization.

Online upgrade

Users can upgrade the firmware online through Ethernet or serial port,which improves the reliability and maintainability of the system.

Powerful data processing capability

The module can collect,store and process a large amount of data,including analog,digital and pulse signals,etc.,which is convenient for users to analyze and process data.

Reliable security mechanism

BENTLY 3500/22M has a complete security mechanism,such as user authority management,data encryption,etc.,which can effectively protect the security of the system and data.

Easy to operate

The module has a simple and easy-to-use interface and operation mode,which is convenient for users to set up,debug and use.

Application field

BENTLY 3500/22M transient data interface module is suitable for various application scenarios of industrial automation and control systems that require high performance and high reliability,such as

The module can be used to monitor the vibration of industrial equipment(such as engines,pumps,fans).Vibration data can be used to predict the health of equipment and help prevent equipment failure.

Mechanical equipment health monitoring

By monitoring the transient data of mechanical equipment,the working status of the equipment can be evaluated,potential problems can be discovered and solved in time,and the reliability and life of the equipment can be improved.

Transient event recording

This module can be used to record and analyze transient events that occur in the equipment,such as sudden voltage changes,shocks,or other unusual working conditions.This is very important for understanding unusual conditions during equipment operation and fault diagnosis.

Power system monitoring

In the power industry,the transient data interface module can be used to monitor parameters such as current,voltage,and frequency in the power system,which helps to ensure the stable operation of the power system.

Factory automation

This module can be integrated into the factory automation system for real-time monitoring of the operating status of production equipment,thereby improving production efficiency and quality.

Safety monitoring

By monitoring the transient data of the equipment,a real-time assessment of the safety performance in the industrial process can be provided,which helps to take necessary safety measures in time.

Product advantages

High reliability

BENTLY 3500/22M is manufactured with high-quality electronic components and materials,and undergoes strict quality control and testing to ensure long-term stable operation in harsh industrial environments.

The module has high-precision data acquisition and processing capabilities,can accurately measure and record various parameters,and provide reliable data support for equipment fault diagnosis and performance optimization.

Easy to integrate

BENTLY 3500/22M supports a variety of communication interfaces and programming methods,making it easy for users to integrate it into existing industrial automation and control systems.

Scalability

The module is scalable,and users can add additional sensors and devices according to actual needs to expand the monitoring and control range of the system.

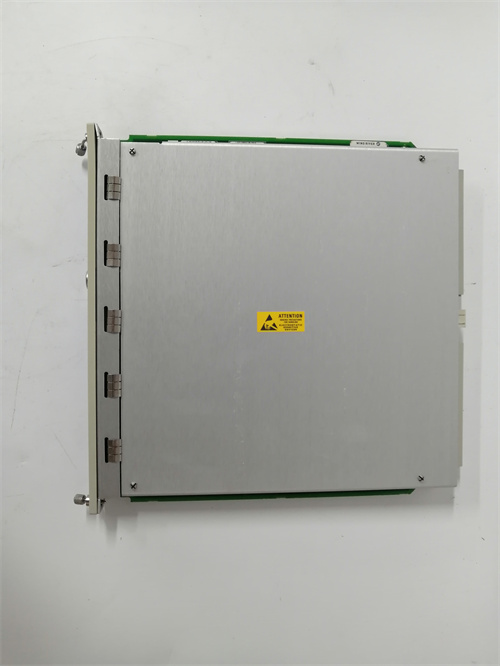

Bently Nevada 3500/22M 138607-01

The part number BENTLY 3500/22M 138607-01 refers to a specific component from the Bently Nevada line of machinery monitoring equipment, commonly used in industrial applications for monitoring the health and performance of rotating machinery.

Buy-Globally

Contact Us for Inquiries & Needs

If you have any questions or needs, please feel free to leave a message. Our customer service is online 24 hours a day, and we look forward to serving you.

Leave a Comment

- All comments(0)

- There are no comments yet. Come and post a comment!

Loading comments...

Loading comments...