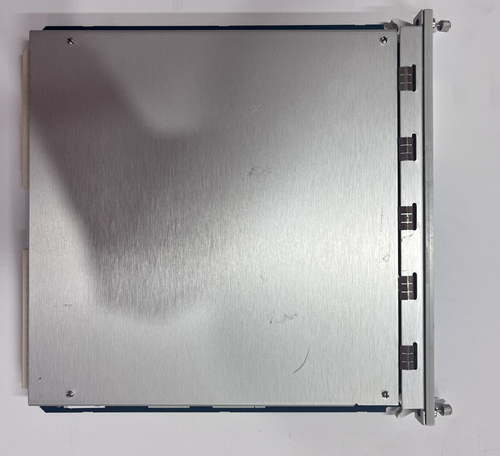

Bently Nevada 3500/91M 190782-01 Monitoring System Module Detailed Technical Overview

BENTLY 3500/91M 190782-01 Monitoring System Module is a module designed for industrial monitoring and diagnosis, specifically for Bently Nevada’s 3500 series monitoring system,Especially suitable for real-time monitoring of equipment such as vibration, temperature, pressure, etc.

This module helps users track equipment status in real-time, predict equipment failures, and improve the safety and reliability of production lines.

Main features

Multi functional monitoring: supports monitoring of various types of equipment such as vibration, temperature, pressure, etc., suitable for different industrial applications.

Real time data processing: Provides real-time data processing capabilities that can quickly respond to changes in device status.

Highly integrated: Integrating multiple functions reduces system complexity and installation space requirements.

Powerful alarm function: The module has a built-in alarm mechanism that issues warnings in a timely manner when device parameters exceed the preset range, helping users respond to potential problems in a timely manner.

High reliability: Adopting a robust industrial grade design, it can operate stably in harsh working environments.

Data collection and storage: Supports data collection, storage, and recording functions, facilitating subsequent analysis and maintenance.

Easy to integrate: It can be easily integrated with other monitoring modules and systems from Bently Nevada, expanding monitoring capabilities.

High precision measurement: Equipped with high-precision sensor inputs to ensure the accuracy and reliability of monitoring data.

Application areas

Equipment Failure Prediction: Real time monitoring of equipment operation status, predicting equipment failures in advance, and reducing downtime.

Mechanical and electrical equipment monitoring: widely used for status monitoring of industrial equipment such as motors, pumps, compressors, generators, etc.

Process control system: used for monitoring the status of equipment in various industrial processes to ensure the smooth progress of the process flow.

Energy management: Monitor the operation status of energy consuming equipment to help improve energy efficiency and system stability.

Wind power generation: Monitor key components of wind power generation equipment to ensure their efficient operation.

Buy-Globally

Contact Us for Inquiries & Needs

If you have any questions or needs, please feel free to leave a message. Our customer service is online 24 hours a day, and we look forward to serving you.

Leave a Comment

- All comments(0)

- There are no comments yet. Come and post a comment!

Loading comments...

Loading comments...