Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

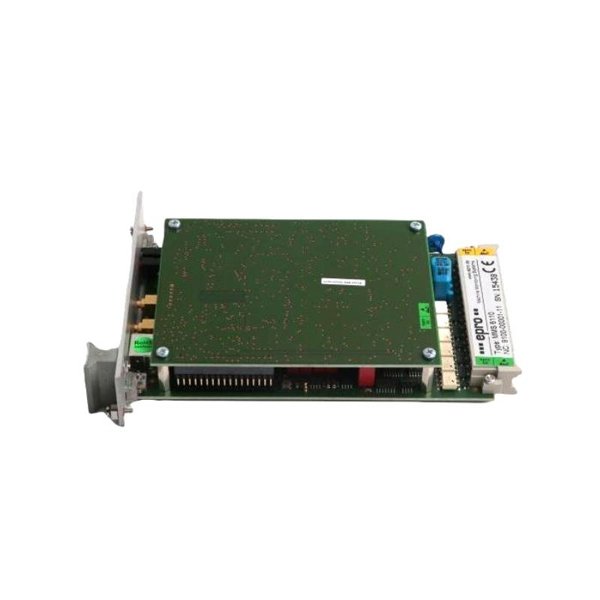

Epro MMS6110 Dual Channel Shaft Vibration Monitor

Manufacturer:Epro

Product Number:MMS6110

Product Type:Dual Channel Shaft Vibration Monitor

Origin:Germany

Dimensions:127.5 x 125.75 x 80 mm

Weight:1.3 kg

Views:57

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Epro MMS6110 is a high-performance machinery monitoring and protection module designed for industrial vibration analysis and predictive maintenance. As part of the MMS 6000 series, it provides real-time monitoring of rotating machinery, helping industries detect early signs of equipment failure and improve operational reliability.

This module is ideal for applications in power plants, oil & gas refineries, chemical plants, manufacturing, and heavy industries. It features multi-channel vibration monitoring, precise signal processing, and seamless integration with SCADA and DCS systems.

The MMS6110 supports a wide range of sensors, including Eddy current probes, accelerometers, and velocity sensors, making it a versatile solution for different industrial needs. With its rugged industrial design, it ensures reliable performance even in harsh environments.

Product Specifications

| Parameter | Details |

|---|---|

| Manufacturer | Epro (A Brand of Emerson) |

| Series | MMS 6000 Machinery Monitoring System |

| Model Number | MMS6110 |

| Function | Vibration and Condition Monitoring |

| Measurement Type | Vibration, Displacement, and Speed Monitoring |

| Input Signal | Compatible with PR6423, PR6424, PR9268 Sensors |

| Output Signal | 4-20mA, Digital, and Relay Outputs |

| Power Supply | 24V DC |

| Accuracy | High precision with low drift |

| Communication | Modbus RTU, Ethernet, and Profibus Interface |

| Operating Temperature | -20°C to 70°C |

| Storage Temperature | -40°C to 85°C |

| Humidity | 5% – 95% (Non-Condensing) |

| Shock Resistance | IEC 60068-2-27 Compliant |

| Vibration Resistance | IEC 60068-2-6 Compliant |

| Housing Material | Industrial-Grade Aluminum |

| Mounting Type | Panel or Rack Mounting |

| Dimensions | 127.5 x 125.75 x 80 mm |

| Weight | 1.3 kg |

Applications of Epro MMS6110

- Turbine Monitoring – Detects imbalances, misalignments, and bearing faults in steam and gas turbines.

- Compressor Condition Monitoring – Ensures continuous operation and failure prevention in gas compressors.

- Pump Protection Systems – Prevents unexpected breakdowns by analyzing vibration trends.

- Oil & Gas Industry – Enhances safety and reliability in offshore and onshore operations.

- Steel & Metal Processing – Monitors rolling mill equipment for early fault detection.

- Paper and Pulp Industry – Reduces unplanned downtime in high-speed processing machines.

- Wind Turbine Monitoring – Identifies gearbox and bearing defects in wind energy applications.

- Hydropower Plant Maintenance – Prevents shaft misalignment and cavitation issues.

- Manufacturing Automation – Ensures smooth operation of industrial robots and CNC machines.

- Aerospace Component Testing – Used in testing vibration levels in aircraft components.

Advantages of Epro MMS6110

- High Accuracy and Reliability – Provides precise vibration monitoring with minimal signal drift.

- Multi-Channel Data Processing – Supports multiple sensor inputs for comprehensive analysis.

- Advanced Fault Detection – Identifies bearing wear, shaft misalignment, and imbalance.

- Seamless System Integration – Works with Modbus, Profibus, and Ethernet for remote monitoring.

- Industrial-Grade Durability – Designed to withstand extreme temperatures, humidity, and mechanical stress.

- Easy Installation & Configuration – Intuitive software interface and flexible mounting options.

- Predictive Maintenance Ready – Reduces unexpected downtime and maintenance costs.

- Low Power Consumption – Operates efficiently on 24V DC power supply.

- User-Friendly Interface – Offers real-time data visualization and alarm notifications.

- Long-Term Cost Savings – Minimizes repair costs and enhances machinery lifespan.

Epro MMS6110 Dual Channel Shaft Vibration Monitor

Manufacturer:Epro

Product Number:MMS6110

Product Type:Dual Channel Shaft Vibration Monitor

Origin:Germany

Dimensions:127.5 x 125.75 x 80 mm

Weight:1.3 kg

Views:57

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Epro MMS6110 is a high-performance machinery monitoring and protection module designed for industrial vibration analysis and predictive maintenance. As part of the MMS 6000 series, it provides real-time monitoring of rotating machinery, helping industries detect early signs of equipment failure and improve operational reliability.

This module is ideal for applications in power plants, oil & gas refineries, chemical plants, manufacturing, and heavy industries. It features multi-channel vibration monitoring, precise signal processing, and seamless integration with SCADA and DCS systems.

The MMS6110 supports a wide range of sensors, including Eddy current probes, accelerometers, and velocity sensors, making it a versatile solution for different industrial needs. With its rugged industrial design, it ensures reliable performance even in harsh environments.

Product Specifications

| Parameter | Details |

|---|---|

| Manufacturer | Epro (A Brand of Emerson) |

| Series | MMS 6000 Machinery Monitoring System |

| Model Number | MMS6110 |

| Function | Vibration and Condition Monitoring |

| Measurement Type | Vibration, Displacement, and Speed Monitoring |

| Input Signal | Compatible with PR6423, PR6424, PR9268 Sensors |

| Output Signal | 4-20mA, Digital, and Relay Outputs |

| Power Supply | 24V DC |

| Accuracy | High precision with low drift |

| Communication | Modbus RTU, Ethernet, and Profibus Interface |

| Operating Temperature | -20°C to 70°C |

| Storage Temperature | -40°C to 85°C |

| Humidity | 5% – 95% (Non-Condensing) |

| Shock Resistance | IEC 60068-2-27 Compliant |

| Vibration Resistance | IEC 60068-2-6 Compliant |

| Housing Material | Industrial-Grade Aluminum |

| Mounting Type | Panel or Rack Mounting |

| Dimensions | 127.5 x 125.75 x 80 mm |

| Weight | 1.3 kg |

Applications of Epro MMS6110

- Turbine Monitoring – Detects imbalances, misalignments, and bearing faults in steam and gas turbines.

- Compressor Condition Monitoring – Ensures continuous operation and failure prevention in gas compressors.

- Pump Protection Systems – Prevents unexpected breakdowns by analyzing vibration trends.

- Oil & Gas Industry – Enhances safety and reliability in offshore and onshore operations.

- Steel & Metal Processing – Monitors rolling mill equipment for early fault detection.

- Paper and Pulp Industry – Reduces unplanned downtime in high-speed processing machines.

- Wind Turbine Monitoring – Identifies gearbox and bearing defects in wind energy applications.

- Hydropower Plant Maintenance – Prevents shaft misalignment and cavitation issues.

- Manufacturing Automation – Ensures smooth operation of industrial robots and CNC machines.

- Aerospace Component Testing – Used in testing vibration levels in aircraft components.

Advantages of Epro MMS6110

- High Accuracy and Reliability – Provides precise vibration monitoring with minimal signal drift.

- Multi-Channel Data Processing – Supports multiple sensor inputs for comprehensive analysis.

- Advanced Fault Detection – Identifies bearing wear, shaft misalignment, and imbalance.

- Seamless System Integration – Works with Modbus, Profibus, and Ethernet for remote monitoring.

- Industrial-Grade Durability – Designed to withstand extreme temperatures, humidity, and mechanical stress.

- Easy Installation & Configuration – Intuitive software interface and flexible mounting options.

- Predictive Maintenance Ready – Reduces unexpected downtime and maintenance costs.

- Low Power Consumption – Operates efficiently on 24V DC power supply.

- User-Friendly Interface – Offers real-time data visualization and alarm notifications.

- Long-Term Cost Savings – Minimizes repair costs and enhances machinery lifespan.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...