Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

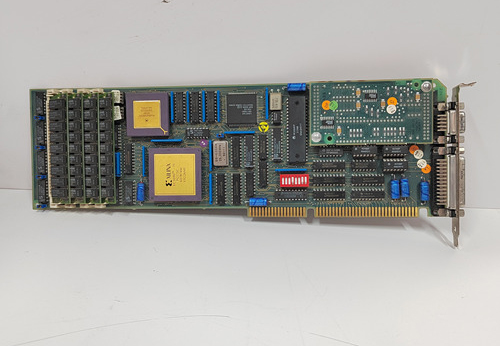

ABB DSQC 325 3HAB2241-1 circuit boards

Manufacturer:ABB

Product Number: DSQC 325 3HAB2241-1

Product Type:circuit boards

Origin:Sweden

Dimensions:160 x 100 x 50 mm

Weight:0.8 kg

Views:100

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB DSQC 325 3HAB2241-1 is a high-performance I/O module designed for industrial automation and robotics applications. It is part of ABB’s renowned DSQC series, known for reliability, flexibility, and seamless integration with ABB’s robotic systems. This module facilitates efficient signal processing and communication between controllers and peripheral devices, making it ideal for demanding industrial environments.

Product Parameters

| Parameter | Specification |

|---|---|

| Model Number | DSQC 325 3HAB2241-1 |

| Input Voltage | 24V DC (±10%) |

| Number of Inputs | 16 digital inputs |

| Number of Outputs | 16 digital outputs |

| Communication | DeviceNet, Profibus, or Ethernet/IP |

| Operating Temp. | 0°C to +55°C |

| Storage Temp. | -25°C to +85°C |

| Humidity Range | 5% to 95% (non-condensing) |

| Dimensions | 160 x 100 x 50 mm |

| Weight | 0.8 kg |

| Protection Rating | IP20 |

| Mounting | DIN rail or panel mounting |

Product Applications

The ABB DSQC 325 3HAB2241-1 is widely used in industrial automation, particularly in robotic systems. Key applications include:

Robotic Welding Systems – Ensures precise control of welding tools and sensors.

Material Handling – Manages conveyor belts, grippers, and sorting mechanisms.

Assembly Lines – Facilitates synchronized operations in automotive and electronics manufacturing.

Packaging Machinery – Controls actuators and sensors for efficient packaging processes.

CNC Machine Integration – Interfaces with CNC controllers for automated machining.

Process Automation – Used in chemical and food processing industries for reliable I/O operations.

Product Advantages

High Reliability – Built with industrial-grade components for long-term durability.

Flexible Communication – Supports multiple protocols (DeviceNet, Profibus, Ethernet/IP).

Easy Integration – Compatible with ABB robots and third-party automation systems.

Compact Design – Saves space in control cabinets while providing high I/O density.

Fast Response Time – Ensures real-time signal processing for high-speed applications.

Robust Construction – Resists vibration, dust, and electrical noise in harsh environments.

Frequently Asked Questions (FAQ)

What communication protocols does the DSQC 325 support?

It supports DeviceNet, Profibus, and Ethernet/IP, depending on configuration.

Can this module be used with non-ABB controllers?

Yes, it is compatible with third-party PLCs and automation systems that support the same protocols.

What is the maximum operating temperature?

The module operates reliably between 0°C and +55°C.

Is the DSQC 325 suitable for outdoor use?

No, it has an IP20 rating and should be installed in a protected enclosure.

How many digital I/O points does it have?

It provides 16 digital inputs and 16 digital outputs.

What power supply is required?

It operates on 24V DC with a ±10% tolerance.

Can additional I/O modules be daisy-chained?

Yes, multiple modules can be networked via supported communication protocols.

What is the expected lifespan of this module?

With proper usage, it can last over 5 years in industrial environments.

Does it require special software for configuration?

Yes, ABB’s RobotStudio or compatible PLC programming tools are needed for setup.

Is the module hot-swappable?

No, power must be disconnected before installation or replacement.

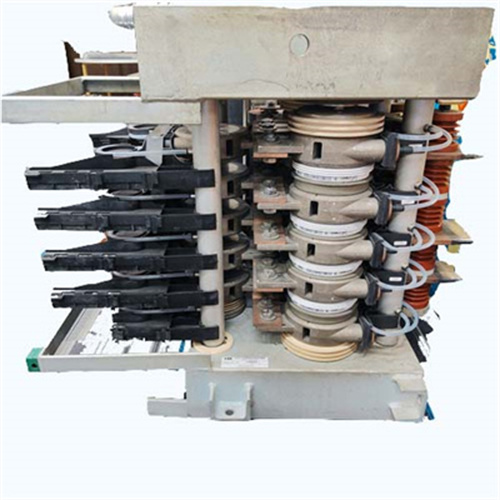

ABB DSQC 325 3HAB2241-1 circuit boards

Manufacturer:ABB

Product Number: DSQC 325 3HAB2241-1

Product Type:circuit boards

Origin:Sweden

Dimensions:160 x 100 x 50 mm

Weight:0.8 kg

Views:100

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB DSQC 325 3HAB2241-1 is a high-performance I/O module designed for industrial automation and robotics applications. It is part of ABB’s renowned DSQC series, known for reliability, flexibility, and seamless integration with ABB’s robotic systems. This module facilitates efficient signal processing and communication between controllers and peripheral devices, making it ideal for demanding industrial environments.

Product Parameters

| Parameter | Specification |

|---|---|

| Model Number | DSQC 325 3HAB2241-1 |

| Input Voltage | 24V DC (±10%) |

| Number of Inputs | 16 digital inputs |

| Number of Outputs | 16 digital outputs |

| Communication | DeviceNet, Profibus, or Ethernet/IP |

| Operating Temp. | 0°C to +55°C |

| Storage Temp. | -25°C to +85°C |

| Humidity Range | 5% to 95% (non-condensing) |

| Dimensions | 160 x 100 x 50 mm |

| Weight | 0.8 kg |

| Protection Rating | IP20 |

| Mounting | DIN rail or panel mounting |

Product Applications

The ABB DSQC 325 3HAB2241-1 is widely used in industrial automation, particularly in robotic systems. Key applications include:

Robotic Welding Systems – Ensures precise control of welding tools and sensors.

Material Handling – Manages conveyor belts, grippers, and sorting mechanisms.

Assembly Lines – Facilitates synchronized operations in automotive and electronics manufacturing.

Packaging Machinery – Controls actuators and sensors for efficient packaging processes.

CNC Machine Integration – Interfaces with CNC controllers for automated machining.

Process Automation – Used in chemical and food processing industries for reliable I/O operations.

Product Advantages

High Reliability – Built with industrial-grade components for long-term durability.

Flexible Communication – Supports multiple protocols (DeviceNet, Profibus, Ethernet/IP).

Easy Integration – Compatible with ABB robots and third-party automation systems.

Compact Design – Saves space in control cabinets while providing high I/O density.

Fast Response Time – Ensures real-time signal processing for high-speed applications.

Robust Construction – Resists vibration, dust, and electrical noise in harsh environments.

Frequently Asked Questions (FAQ)

What communication protocols does the DSQC 325 support?

It supports DeviceNet, Profibus, and Ethernet/IP, depending on configuration.

Can this module be used with non-ABB controllers?

Yes, it is compatible with third-party PLCs and automation systems that support the same protocols.

What is the maximum operating temperature?

The module operates reliably between 0°C and +55°C.

Is the DSQC 325 suitable for outdoor use?

No, it has an IP20 rating and should be installed in a protected enclosure.

How many digital I/O points does it have?

It provides 16 digital inputs and 16 digital outputs.

What power supply is required?

It operates on 24V DC with a ±10% tolerance.

Can additional I/O modules be daisy-chained?

Yes, multiple modules can be networked via supported communication protocols.

What is the expected lifespan of this module?

With proper usage, it can last over 5 years in industrial environments.

Does it require special software for configuration?

Yes, ABB’s RobotStudio or compatible PLC programming tools are needed for setup.

Is the module hot-swappable?

No, power must be disconnected before installation or replacement.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...