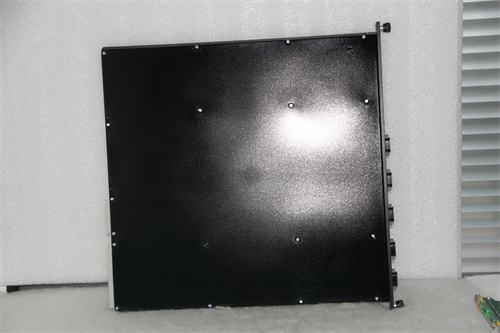

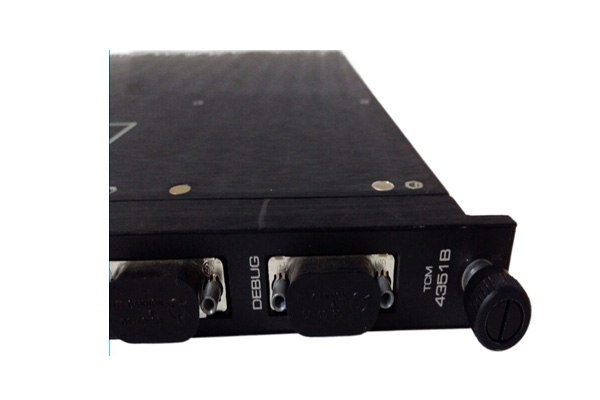

TRICONEX 4351B Product Overview

The TRICONEX 4351B module is an important part of the TRICONEX control system and is responsible for realizing data communication between components within the system.It uses advanced hardware technology and reliable software design to ensure the real-time and accuracy of data communication.This module is widely used in many fields such as oil,natural gas,chemical,electric power,pharmaceutical,food processing,railway transportation,water treatment and manufacturing,providing stable and efficient monitoring and control solutions for industrial automation and control systems.

Technical Specifications and Functions

Processor and Memory

Processor:It may use a 32-bit processor with a main frequency of 33MHz(the specific model may vary depending on the configuration).

Memory:Equipped with 1MB RAM and 4MB flash memory(if it is a PLC type)for storing and processing data.

Supports multiple communication interfaces,such as Ethernet,serial port,CAN bus,etc.,to facilitate data exchange with other devices and systems.

Supports multiple communication protocols such as Modbus,DNP3,OPC,etc.to ensure interoperability with different devices and systems.

Digital input(such as digital input module)

It has multiple digital input channels for monitoring and collecting digital signals such as switch status and sensor status.

It supports alias configuration for read and write operations of Modbus devices.

Other functions

It supports real-time data transmission,can quickly process input signals and control output signals in real time.

It has fault detection and alarm functions,can monitor communication failures in real time,and generate alarms and notifications when necessary.

It adopts high-reliability design and materials,and can operate stably in harsh industrial environments.

Product Features

High performance:It adopts advanced processors and large-capacity memory to quickly process complex tasks and large amounts of data.

High reliability:It adopts redundant design(such as dual processors and dual power input)to ensure that the system can still operate normally when a single component fails.

Easy to integrate and maintain:It integrates seamlessly with other TRICONEX devices and system components to build a complete control and monitoring system.At the same time,the design is easy to troubleshoot and upgrade functions,reducing maintenance costs and time.

Flexibility and scalability:It can be customized and expanded according to specific application requirements,suitable for various scenarios from small factories to large industrial projects.

Application fields

Oil and gas industry:used for automation and control of oil and gas production,transportation and processing processes to ensure the safety and efficiency of production lines.

Chemical industry:monitor and control chemical reactions,mixing,separation and transmission processes in chemical plants and process units to ensure product quality and plant safety.

Power industry:used to monitor power generation and transmission processes to ensure the reliability and stability of power systems.

Pharmaceutical and food processing:automate drug production processes in pharmaceutical production to ensure production compliance and quality control;control production lines in food processing and packaging to ensure product safety and consistency.

Railway and transportation:ensure the safe operation of trains and transportation systems in railway signal control and transportation systems.

Water treatment:monitor and control water quality,water pressure and water flow in water treatment plants to ensure the normal operation of water supply systems.

Manufacturing:used for automated production processes,machine control and quality inspection in various manufacturing plants.

Triconex 4351B

TRICONEX 4351B is a high-performance, fault-tolerant programmable logic controller (PLC) designed specifically for critical control and safety applications. The following is a detailed introduction about TRICONEX 4351B

Buy-Globally

Contact Us for Inquiries & Needs

If you have any questions or needs, please feel free to leave a message. Our customer service is online 24 hours a day, and we look forward to serving you.

Leave a Comment

- All comments(0)

- There are no comments yet. Come and post a comment!

Loading comments...

Loading comments...