Allen‑Bradley 1756-RM Product Overview

Allen‑Bradley 1756-RM redundant module is designed to improve the reliability and fault tolerance of industrial automation systems.It is usually integrated with other modules and devices of the ControlLogix series to establish a redundantly configured industrial automation and control system.

Main features

Redundant configuration:Allen‑Bradley 1756-RM supports redundant settings,in which two or more modules run simultaneously to ensure that the system can still maintain operation when one module fails.

Condition monitoring:The redundant module has a condition monitoring function that can monitor the operating status of the module in real time,allowing operators to understand the health of the system in a timely manner.

Hot plug:Some Allen‑Bradley 1756-RM redundant modules support hot plug function,that is,the module can be unplugged or plugged in while the system is running without affecting the operation of the entire system.

Communication interface:Redundant modules usually need to communicate with other modules and devices to coordinate the operation of the system.Allen‑Bradley 1756-RM uses a high-reliability communication interface to ensure the stability and accuracy of data transmission.

Application scope:Allen‑Bradley 1756-RM redundancy module is suitable for industrial automation and control applications that require high reliability and fault tolerance,such as manufacturing,process control,etc.

Technical specifications(taking Allen‑Bradley 1756-RM2 as an example)

Operating voltage:24V DC

Operating temperature:-20℃to 70℃(operating),-40℃to 85℃(storage)

Dimensions:178mm x 35mm x 87mm

Weight:0.25kg

Network support:Supports 2 pluggable media modules and 4 10/100Mbps adaptive Ethernet ports,supports SNMP v1/v2c/v3 management,VLAN,QoS,IGMP Snooping and other network protocols,as well as RSTP,STP and other network protocols.

Performance:When paired with the 1756-L7x controller in two chassis,it can provide the best scanning performance with a speed of up to 1000 Mbps.

Application scenarios

Production automation:used to control and monitor equipment on the production line to improve production efficiency,reduce human intervention and ensure product quality.

Process control:in process industries such as chemical,petroleum,and natural gas,it is used to monitor and adjust process parameters to ensure the safety and stable operation of the process.

Machinery control:in mechanical engineering,it is used to control and monitor the state,position and movement of the machine.

Building automation:in large buildings,it is used to control lighting,air conditioning,security systems,etc.

Energy management:used to monitor and control energy systems to improve energy efficiency and reduce energy costs.

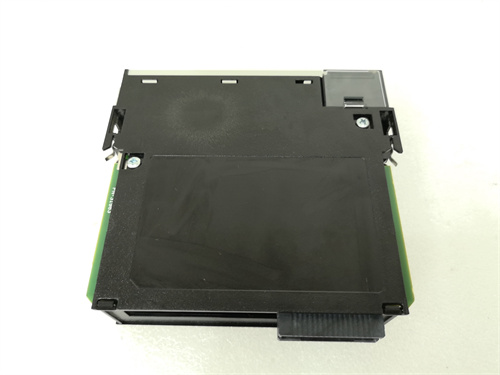

Allen-Bradley 1756-RM2/A

The Allen Bradley 1756-RM2/A is a ControlLogix Redundancy Module designed to improve system reliability and uptime. By pairing two modules in separate ControlLogix chassis, you create a redundant system. The system automatically sw

Buy-Globally

Contact Us for Inquiries & Needs

If you have any questions or needs, please feel free to leave a message. Our customer service is online 24 hours a day, and we look forward to serving you.

Leave a Comment

- All comments(0)

- There are no comments yet. Come and post a comment!

Loading comments...

Loading comments...