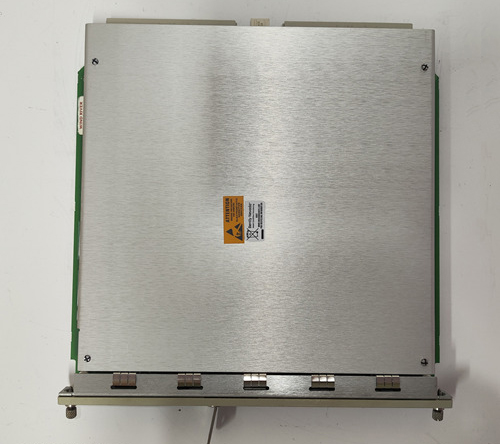

Bently 3500/22M 138607-01 Transient Data Interface Module Product Overview

The Bently 3500/22M 138607-01 Transient Data Interface Module is part of the Bently 3500 series, designed specifically for capturing and processing device transient data. The following are the main features of this module:

Function: Used for real-time collection and recording of transient data of devices, helping users monitor sudden changes in device behavior during operation (such as changes during startup, shutdown, or failure).

Data capture: capable of capturing high-speed, short-term transient events and storing the data for subsequent analysis, helping to identify and diagnose potential equipment problems.

High precision: Provides high-precision data acquisition, especially suitable for monitoring the dynamic behavior of key equipment such as high-speed rotating machinery, pumps, fans, etc.

Alarm and analysis: Real time alarms can be generated based on captured data, and data reports can be generated to help maintenance personnel detect signs of equipment failure or performance degradation in a timely manner.

Compatibility: Compatible with other monitoring modules in the Bently 3500 series, it can work in conjunction with vibration, temperature, current, and other monitoring modules to provide comprehensive equipment health monitoring.

Output signal: The module provides standard output signals, facilitating the integration of data with other systems for further analysis or control.

Installation method: Adopting a slot design, it is easy to install in Bently 3500 series racks and supports system expansion and upgrading.

Application areas: Widely used in power, oil and gas, chemical and other industrial fields, especially providing important transient data support when monitoring critical rotating equipment.

Environmental adaptability: The module design conforms to industrial standards, has strong anti-interference ability, and can work stably in complex and harsh industrial environments.

Diagnostic support: Assist engineers in early warning of potential faults through transient data analysis of equipment startup, shutdown processes, and sudden dynamic changes during operation.

Bently Nevada 3500/22M 138607-01

The BENTLY 3500/22M 138607-01 module is an interface module produced by Bently Nevada and widely used in vibration monitoring systems. The following is a detailed introduction to this module. 1、 Basic information Brand and model: BENTLY N

Buy-Globally

Contact Us for Inquiries & Needs

If you have any questions or needs, please feel free to leave a message. Our customer service is online 24 hours a day, and we look forward to serving you.

Leave a Comment

- All comments(0)

- There are no comments yet. Come and post a comment!

Loading comments...

Loading comments...