Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

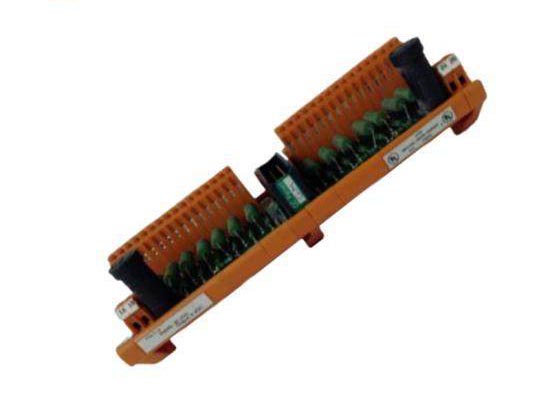

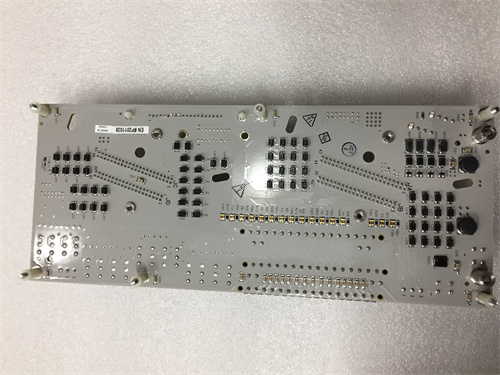

Honeywell 900RR0-0200 Redundant Controller Rack

Manufacturer:Honeywell

Product Number:900RR0-0200

Product Type:Redundant Controller Rack

Origin:USA

Dimensions:137 x 261.6 x 151.7 mm

Weight:0.175 kg

Views:52

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

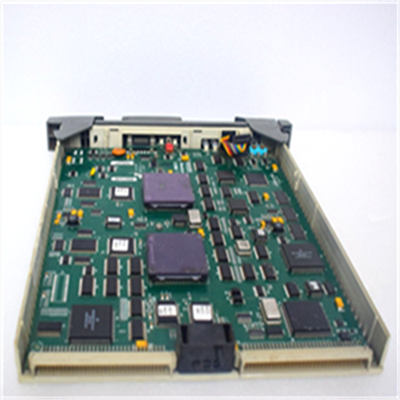

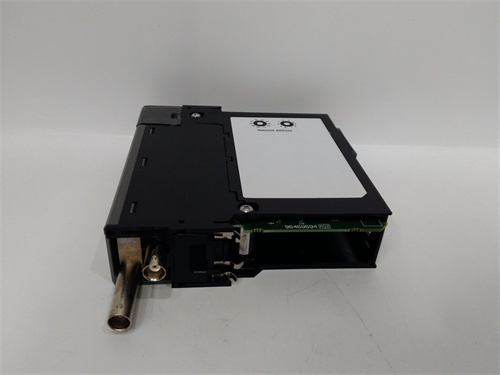

The Honeywell 900RR0-0200 Redundant Controller Rack is an essential component of the HC900 Hybrid Controller platform, specifically designed to house redundant controllers and provide a reliable backbone for critical process and safety applications. It supports dual CPU modules, redundant power supply connections, and modular I/O configurations, ensuring uninterrupted control even in the event of hardware or communication failures.

As part of Honeywell’s HC900 series, the 900RR0-0200 offers both scalability and high availability, making it suitable for demanding industrial environments where downtime is not acceptable. By integrating process control, logic, and safety in a single platform, this rack provides a central, secure, and efficient system structure for industries that require continuous operations.

Product Specifications

| Parameter | Description |

|---|---|

| Model | Honeywell 900RR0-0200 |

| Product Type | Redundant Controller Rack |

| Supported Controllers | Dual HC900 CPU modules (redundant configuration) |

| I/O Capacity | Supports up to 4,000 I/O points depending on system configuration |

| Communication Ports | Backplane bus connection, Ethernet, Modbus TCP/IP |

| Redundancy Support | CPU redundancy, power supply redundancy, communication redundancy |

| Power Supply | 24 V DC nominal (18–32 V DC range) |

| Operating Temperature | 0–60 °C |

| Storage Temperature | -20–70 °C |

| Humidity Range | 5–95% RH, non-condensing |

| Mounting | Rack-mounted with modular slots |

| Materials | Industrial-grade enclosure, corrosion-resistant |

| Standards Compliance | CE, UL, CSA, IEC/EN 61131 |

| Dimensions | 137 x 261.6 x 151.7 mm |

| Weight | 0.175 kg |

Product Applications

The 900RR0-0200 Redundant Controller Rack is widely used in industries where control system reliability and high availability are mission-critical. Its applications include:

Power Generation – Ensures redundancy for turbine auxiliaries, boiler management, and plant safety systems.

Petrochemical and Refining – Provides continuous operation for distillation, reactor control, and safety interlocks.

Pharmaceutical Production – Used for batch control, sterilization processes, and compliance with strict standards.

Food & Beverage Industry – Guarantees redundancy for recipe control, pasteurization, and production line sequencing.

Water and Wastewater Treatment – Maintains uninterrupted operations in pumping, dosing, and filtering systems.

Metals and Mining – Provides reliable monitoring and safety for smelting, rolling mills, and furnace control.

Product Advantages

High Availability Design – Built to support redundant CPU modules, minimizing downtime.

Scalable Platform – Compatible with multiple I/O modules, allowing system expansion.

Integrated Redundancy – Supports redundancy at CPU, power, and communication levels.

Industrial-Grade Reliability – Engineered for harsh industrial environments.

Flexible Integration – Compatible with Honeywell Experion® PKS and other SCADA systems.

Efficient Maintenance – Hot-swappable modules minimize disruption during servicing.

Strong Security – Rack architecture supports secure controller placement and reliable data flow.

Global Compliance – Certified to international standards for industrial automation.

FAQ

How many CPU modules can be installed in the 900RR0-0200 rack?

The rack supports two CPU modules for full redundancy.

Does the rack support hot-swapping of modules?

Yes, it supports hot-swapping of power supply and I/O modules to minimize downtime.

What communication interfaces are available in the rack?

The rack provides backplane communication, Ethernet, and Modbus TCP/IP connectivity.

Can the rack be used for safety instrumented functions?

Yes, with the proper configuration, it supports safety applications in compliance with SIL standards.

What is the maximum I/O capacity supported by the rack?

The rack supports up to 4,000 I/O points depending on system configuration.

Does the rack provide power supply redundancy?

Yes, it supports dual redundant power supply units for continuous operation.

What diagnostic features are available?

The rack provides diagnostics for CPU health, power supply status, communication integrity, and I/O status.

Can the rack be integrated with third-party SCADA systems?

Yes, it supports standard protocols such as Modbus TCP/IP for third-party integration.

What is the typical scan cycle for systems using this rack?

With HC900 CPUs installed, the system can achieve scan cycles as fast as 10 ms.

Is redundancy automatic in case of CPU failure?

Yes, the secondary CPU takes over automatically if the primary CPU fails.

Honeywell 900RR0-0200 Redundant Controller Rack

Manufacturer:Honeywell

Product Number:900RR0-0200

Product Type:Redundant Controller Rack

Origin:USA

Dimensions:137 x 261.6 x 151.7 mm

Weight:0.175 kg

Views:52

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell 900RR0-0200 Redundant Controller Rack is an essential component of the HC900 Hybrid Controller platform, specifically designed to house redundant controllers and provide a reliable backbone for critical process and safety applications. It supports dual CPU modules, redundant power supply connections, and modular I/O configurations, ensuring uninterrupted control even in the event of hardware or communication failures.

As part of Honeywell’s HC900 series, the 900RR0-0200 offers both scalability and high availability, making it suitable for demanding industrial environments where downtime is not acceptable. By integrating process control, logic, and safety in a single platform, this rack provides a central, secure, and efficient system structure for industries that require continuous operations.

Product Specifications

| Parameter | Description |

|---|---|

| Model | Honeywell 900RR0-0200 |

| Product Type | Redundant Controller Rack |

| Supported Controllers | Dual HC900 CPU modules (redundant configuration) |

| I/O Capacity | Supports up to 4,000 I/O points depending on system configuration |

| Communication Ports | Backplane bus connection, Ethernet, Modbus TCP/IP |

| Redundancy Support | CPU redundancy, power supply redundancy, communication redundancy |

| Power Supply | 24 V DC nominal (18–32 V DC range) |

| Operating Temperature | 0–60 °C |

| Storage Temperature | -20–70 °C |

| Humidity Range | 5–95% RH, non-condensing |

| Mounting | Rack-mounted with modular slots |

| Materials | Industrial-grade enclosure, corrosion-resistant |

| Standards Compliance | CE, UL, CSA, IEC/EN 61131 |

| Dimensions | 137 x 261.6 x 151.7 mm |

| Weight | 0.175 kg |

Product Applications

The 900RR0-0200 Redundant Controller Rack is widely used in industries where control system reliability and high availability are mission-critical. Its applications include:

Power Generation – Ensures redundancy for turbine auxiliaries, boiler management, and plant safety systems.

Petrochemical and Refining – Provides continuous operation for distillation, reactor control, and safety interlocks.

Pharmaceutical Production – Used for batch control, sterilization processes, and compliance with strict standards.

Food & Beverage Industry – Guarantees redundancy for recipe control, pasteurization, and production line sequencing.

Water and Wastewater Treatment – Maintains uninterrupted operations in pumping, dosing, and filtering systems.

Metals and Mining – Provides reliable monitoring and safety for smelting, rolling mills, and furnace control.

Product Advantages

High Availability Design – Built to support redundant CPU modules, minimizing downtime.

Scalable Platform – Compatible with multiple I/O modules, allowing system expansion.

Integrated Redundancy – Supports redundancy at CPU, power, and communication levels.

Industrial-Grade Reliability – Engineered for harsh industrial environments.

Flexible Integration – Compatible with Honeywell Experion® PKS and other SCADA systems.

Efficient Maintenance – Hot-swappable modules minimize disruption during servicing.

Strong Security – Rack architecture supports secure controller placement and reliable data flow.

Global Compliance – Certified to international standards for industrial automation.

FAQ

How many CPU modules can be installed in the 900RR0-0200 rack?

The rack supports two CPU modules for full redundancy.

Does the rack support hot-swapping of modules?

Yes, it supports hot-swapping of power supply and I/O modules to minimize downtime.

What communication interfaces are available in the rack?

The rack provides backplane communication, Ethernet, and Modbus TCP/IP connectivity.

Can the rack be used for safety instrumented functions?

Yes, with the proper configuration, it supports safety applications in compliance with SIL standards.

What is the maximum I/O capacity supported by the rack?

The rack supports up to 4,000 I/O points depending on system configuration.

Does the rack provide power supply redundancy?

Yes, it supports dual redundant power supply units for continuous operation.

What diagnostic features are available?

The rack provides diagnostics for CPU health, power supply status, communication integrity, and I/O status.

Can the rack be integrated with third-party SCADA systems?

Yes, it supports standard protocols such as Modbus TCP/IP for third-party integration.

What is the typical scan cycle for systems using this rack?

With HC900 CPUs installed, the system can achieve scan cycles as fast as 10 ms.

Is redundancy automatic in case of CPU failure?

Yes, the secondary CPU takes over automatically if the primary CPU fails.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...