Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

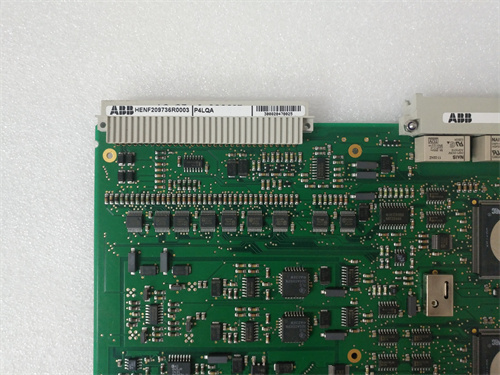

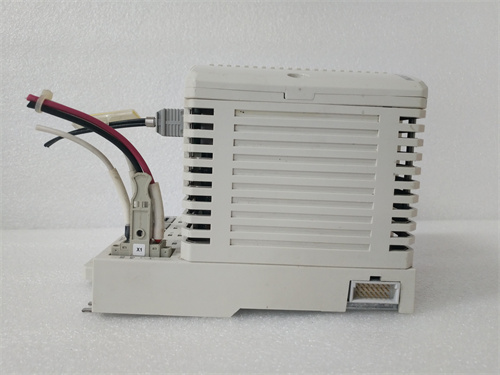

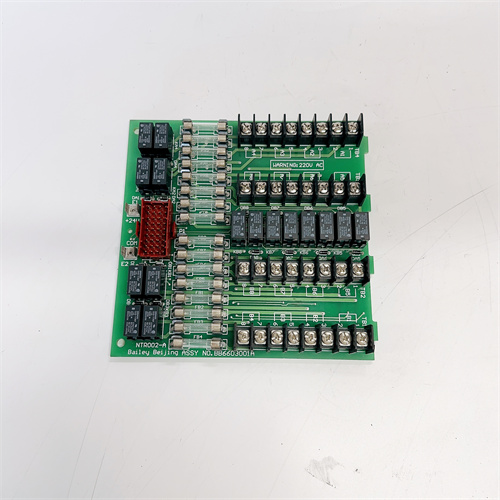

ABB AFIN-02C 3AXD50000038423 Motor Control Board

Manufacturer:ABB

Product Number:AFIN-02C 3AXD50000038423

Product Type:Motor Control Board

Origin:Sweden

Dimensions:140 × 100 × 30 mm

Weight:0.14 kg

Views:36

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB PM571 1SAY130110R0100 CPU Module is a powerful and flexible controller designed as part of the ABB AC500 PLC platform. The PM571 module is tailored to meet the needs of industrial automation systems requiring compact, scalable, and high-performance control. It provides seamless integration into ABB’s modular AC500 architecture, allowing users to create both small stand-alone control systems and complex distributed automation networks.

This CPU module features built-in digital and analog I/O, multiple communication ports, and support for several fieldbus standards. The PM571 supports all IEC 61131-3 programming languages via ABB Automation Builder software, giving engineers the flexibility to build highly customized automation applications.

Engineered for performance and reliability, the PM571 1SAY130110R0100 is well-suited for use across a broad range of industries including machine automation, process industries, utilities, infrastructure, energy, and building automation. Its robust build, diagnostic features, and flexible connectivity make it an ideal controller for demanding environments where space, performance, and versatility are equally important.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | PM571 1SAY130110R0100 |

| Product Type | CPU Module |

| System Platform | ABB AC500 PLC |

| Processor | 32-bit RISC CPU |

| Program Memory | 1 MB |

| Data Memory | 512 KB |

| Retentive Memory | 256 KB |

| Onboard Digital Inputs | 10 channels |

| Onboard Digital Outputs | 6 channels |

| Onboard Analog Inputs | 2 channels |

| Onboard Analog Outputs | 2 channels |

| Real-Time Clock | Yes, with battery backup |

| Communication Ports | 1 x RS-232 (serial), 1 x USB, CANopen (optional), 1 x Ethernet (optional) |

| Supported Fieldbus Protocols | Modbus RTU, Modbus TCP, CANopen (with module) |

| Programming Languages | IEC 61131-3 (LD, FBD, ST, IL, SFC) |

| I/O Expansion Support | Up to 10 S500 I/O modules |

| Typical Scan Cycle | ~1 ms |

| Task Management | Multitasking with priority levels |

| Diagnostics | Integrated system diagnostics |

| Firmware Upgrade | Yes, via USB or Ethernet |

| Power Supply Voltage | 24 VDC ±20% |

| Power Consumption | 5 W |

| Operating Temperature Range | 0°C to +60°C |

| Storage Temperature Range | -25°C to +70°C |

| Humidity | 5% to 95% non-condensing |

| Dimensions (H x W x D) | 140 × 100 × 30 mm |

| Weight | 0.14 kg |

| Mounting Method | DIN rail mounting |

| Certifications | CE, cULus, RoHS, ATEX Zone 2 certified |

Applications

Machine Automation: Small and mid-size machinery control, packaging systems, CNC control

Water & Wastewater: Local control of pump stations, filtration, and treatment plants

HVAC and Building Management: Smart control of lighting, ventilation, and security

Renewable Energy: Control of wind turbines, solar power plants, battery management systems

Power Generation & Distribution: Substation automation, switchgear control

Transportation Infrastructure: Tunnel systems, airports, rail networks

Food & Beverage: Processing lines, bottling, packaging, batch control

OEM Equipment: Compact control for specialized industrial equipment

Mining & Metals: Field control of mining machines and conveyor systems

Utilities & Public Services: Monitoring and control of distributed systems

Product Advantages

Compact Size: Small footprint fits space-constrained control cabinets

Integrated I/O: Built-in digital and analog channels reduce wiring complexity

High Performance: Fast processing for real-time machine control

Flexible Connectivity: Supports Modbus RTU, Modbus TCP, CANopen (with module)

Modular Expansion: Compatible with ABB S500 I/O modules for scalability

Industrial Reliability: Designed for 24/7 operation in harsh environments

Comprehensive Diagnostics: Built-in status LEDs and extensive software diagnostics

Standard Programming: Supports IEC 61131-3 languages, simplifying programming

Global Certifications: Complies with CE, UL, ATEX Zone 2 industrial standards

Cost-Effective: Ideal balance of performance and price for OEM and small automation systems

Frequently Asked Questions (FAQ)

How much program memory is available on the PM571 1SAY130110R0100?

The CPU offers 1 MB of program memory.

What types of onboard I/O are included?

It has 10 digital inputs, 6 digital outputs, 2 analog inputs, and 2 analog outputs.

Does the CPU support Ethernet communication?

Yes, Ethernet can be added via an expansion module.

What programming software is used?

ABB Automation Builder software supports this CPU.

Can the PM571 be used in redundant CPU systems?

No, redundancy is not supported; consider higher-end CPUs for redundancy.

Is this CPU suitable for harsh industrial environments?

Yes, it supports -25°C to +70°C storage and 0°C to +60°C operating temperature ranges.

How many I/O modules can I connect to this CPU?

Up to 10 S500 I/O modules can be added.

Can I upgrade firmware on the CPU?

Yes, firmware can be upgraded through USB or Ethernet.

Does the CPU have a built-in real-time clock?

Yes, with a battery backup to maintain time during power loss.

Which communication protocols does it support?

Modbus RTU, Modbus TCP, and CANopen (with expansion).

ABB AFIN-02C 3AXD50000038423 Motor Control Board

Manufacturer:ABB

Product Number:AFIN-02C 3AXD50000038423

Product Type:Motor Control Board

Origin:Sweden

Dimensions:140 × 100 × 30 mm

Weight:0.14 kg

Views:36

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB PM571 1SAY130110R0100 CPU Module is a powerful and flexible controller designed as part of the ABB AC500 PLC platform. The PM571 module is tailored to meet the needs of industrial automation systems requiring compact, scalable, and high-performance control. It provides seamless integration into ABB’s modular AC500 architecture, allowing users to create both small stand-alone control systems and complex distributed automation networks.

This CPU module features built-in digital and analog I/O, multiple communication ports, and support for several fieldbus standards. The PM571 supports all IEC 61131-3 programming languages via ABB Automation Builder software, giving engineers the flexibility to build highly customized automation applications.

Engineered for performance and reliability, the PM571 1SAY130110R0100 is well-suited for use across a broad range of industries including machine automation, process industries, utilities, infrastructure, energy, and building automation. Its robust build, diagnostic features, and flexible connectivity make it an ideal controller for demanding environments where space, performance, and versatility are equally important.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | PM571 1SAY130110R0100 |

| Product Type | CPU Module |

| System Platform | ABB AC500 PLC |

| Processor | 32-bit RISC CPU |

| Program Memory | 1 MB |

| Data Memory | 512 KB |

| Retentive Memory | 256 KB |

| Onboard Digital Inputs | 10 channels |

| Onboard Digital Outputs | 6 channels |

| Onboard Analog Inputs | 2 channels |

| Onboard Analog Outputs | 2 channels |

| Real-Time Clock | Yes, with battery backup |

| Communication Ports | 1 x RS-232 (serial), 1 x USB, CANopen (optional), 1 x Ethernet (optional) |

| Supported Fieldbus Protocols | Modbus RTU, Modbus TCP, CANopen (with module) |

| Programming Languages | IEC 61131-3 (LD, FBD, ST, IL, SFC) |

| I/O Expansion Support | Up to 10 S500 I/O modules |

| Typical Scan Cycle | ~1 ms |

| Task Management | Multitasking with priority levels |

| Diagnostics | Integrated system diagnostics |

| Firmware Upgrade | Yes, via USB or Ethernet |

| Power Supply Voltage | 24 VDC ±20% |

| Power Consumption | 5 W |

| Operating Temperature Range | 0°C to +60°C |

| Storage Temperature Range | -25°C to +70°C |

| Humidity | 5% to 95% non-condensing |

| Dimensions (H x W x D) | 140 × 100 × 30 mm |

| Weight | 0.14 kg |

| Mounting Method | DIN rail mounting |

| Certifications | CE, cULus, RoHS, ATEX Zone 2 certified |

Applications

Machine Automation: Small and mid-size machinery control, packaging systems, CNC control

Water & Wastewater: Local control of pump stations, filtration, and treatment plants

HVAC and Building Management: Smart control of lighting, ventilation, and security

Renewable Energy: Control of wind turbines, solar power plants, battery management systems

Power Generation & Distribution: Substation automation, switchgear control

Transportation Infrastructure: Tunnel systems, airports, rail networks

Food & Beverage: Processing lines, bottling, packaging, batch control

OEM Equipment: Compact control for specialized industrial equipment

Mining & Metals: Field control of mining machines and conveyor systems

Utilities & Public Services: Monitoring and control of distributed systems

Product Advantages

Compact Size: Small footprint fits space-constrained control cabinets

Integrated I/O: Built-in digital and analog channels reduce wiring complexity

High Performance: Fast processing for real-time machine control

Flexible Connectivity: Supports Modbus RTU, Modbus TCP, CANopen (with module)

Modular Expansion: Compatible with ABB S500 I/O modules for scalability

Industrial Reliability: Designed for 24/7 operation in harsh environments

Comprehensive Diagnostics: Built-in status LEDs and extensive software diagnostics

Standard Programming: Supports IEC 61131-3 languages, simplifying programming

Global Certifications: Complies with CE, UL, ATEX Zone 2 industrial standards

Cost-Effective: Ideal balance of performance and price for OEM and small automation systems

Frequently Asked Questions (FAQ)

How much program memory is available on the PM571 1SAY130110R0100?

The CPU offers 1 MB of program memory.

What types of onboard I/O are included?

It has 10 digital inputs, 6 digital outputs, 2 analog inputs, and 2 analog outputs.

Does the CPU support Ethernet communication?

Yes, Ethernet can be added via an expansion module.

What programming software is used?

ABB Automation Builder software supports this CPU.

Can the PM571 be used in redundant CPU systems?

No, redundancy is not supported; consider higher-end CPUs for redundancy.

Is this CPU suitable for harsh industrial environments?

Yes, it supports -25°C to +70°C storage and 0°C to +60°C operating temperature ranges.

How many I/O modules can I connect to this CPU?

Up to 10 S500 I/O modules can be added.

Can I upgrade firmware on the CPU?

Yes, firmware can be upgraded through USB or Ethernet.

Does the CPU have a built-in real-time clock?

Yes, with a battery backup to maintain time during power loss.

Which communication protocols does it support?

Modbus RTU, Modbus TCP, and CANopen (with expansion).

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...