Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

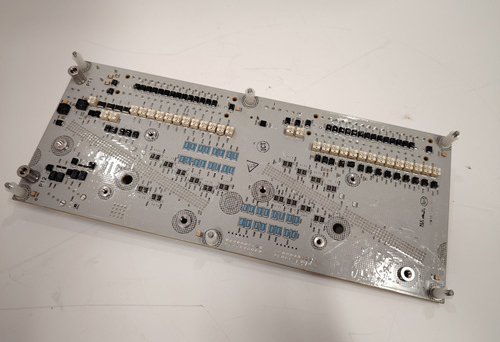

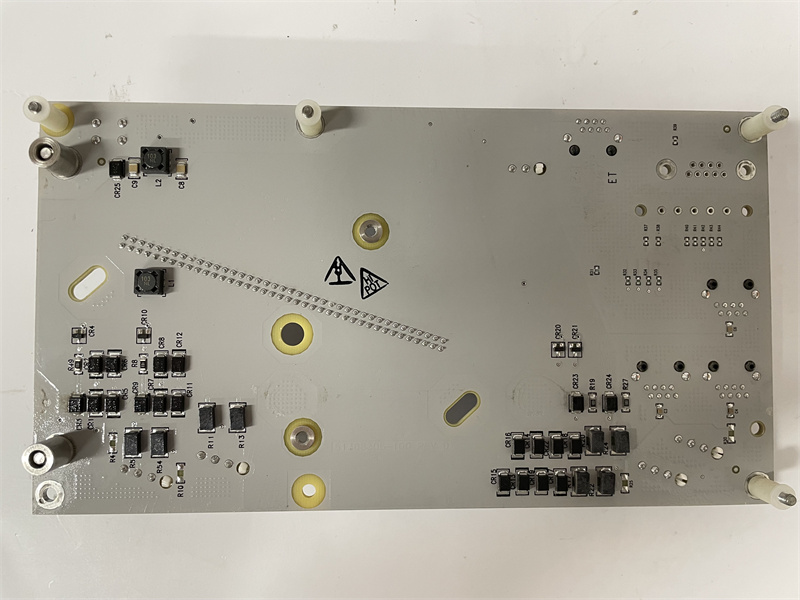

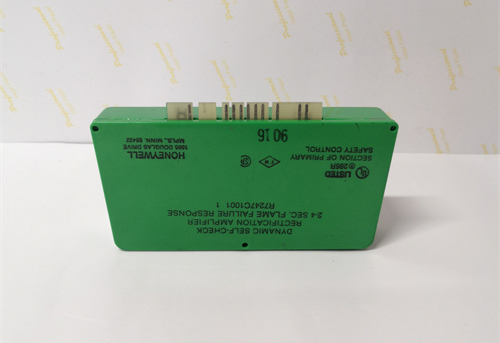

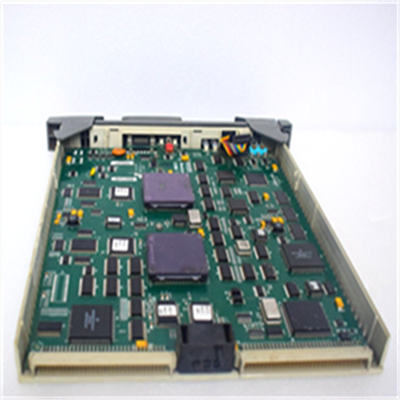

Honeywell 900C52-0243-00 HC900 C50 Controller CPU

Manufacturer:Honeywell

Product Number:900C52-0243-00

Product Type:HC900 C50 Controller CPU

Origin:USA

Dimensions:114 x 176 x 114 mm

Weight:0.13 kg

Views:43

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell 900C52-0243-00 is the HC900 C50 Controller CPU, part of the Honeywell HC900 Hybrid Controller series, designed for process control and safety applications across various industries. It integrates control, data acquisition, and communication functionalities into a scalable and robust platform.

Built for mid-range and high-performance applications, the C50 CPU supports analog and digital I/O modules, advanced control strategies, peer-to-peer communications, and redundancy features. It is widely used in critical sectors such as chemical, pharmaceutical, thermal processing, and water treatment facilities, where reliable and deterministic control is essential.

The HC900 C50 CPU seamlessly communicates with HMIs, SCADA systems, and peer controllers, ensuring centralized and distributed control. Its robust real-time operating system ensures consistent control even in harsh environments.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | 900C52-0243-00 |

| Product Name | HC900 C50 Controller CPU |

| System Type | Hybrid Controller |

| CPU Performance Class | C50 |

| Memory | 1 MB user memory (non-volatile); 32 KB battery-backed RAM |

| Execution Speed | 25 ms scan rate for 500 I/O points |

| Redundancy | Optional CPU and power redundancy |

| Communication Ports | 2 Ethernet 10/100Base-T ports (Modbus TCP, peer-to-peer, HMI) |

| 1 RS-485 serial port (Modbus RTU Slave) | |

| Modbus Support | Modbus RTU (slave), Modbus TCP/IP (master/slave) |

| Max I/O Capacity | Up to 4,000 I/O points |

| Control Loops | Supports up to 100 PID loops |

| Programming Software | Honeywell Hybrid Control Designer (HCD) |

| Mounting | DIN rail or panel mount |

| Power Supply | 24 VDC (via separate power module) |

| Operating Temperature | 0°C to +60°C (32°F to 140°F) |

| Storage Temperature | –40°C to +85°C (–40°F to 185°F) |

| Dimensions (H × W × D) | 114 x 176 x 114 mm |

| Weight | 0.13 kg |

| Certifications | CE, UL, CSA, RoHS, FM, Class I Div 2 approval (select models) |

Applications

The Honeywell HC900 C50 Controller CPU is designed for mid-sized industrial applications requiring precision, flexibility, and robust integration. Common applications include:

Thermal Processing – Batch ovens, kilns, heat treat furnaces, autoclaves.

Water & Wastewater Treatment – Process logic and flow control for treatment plants.

Pharmaceutical Manufacturing – Supports batch control and recipe-based processing.

Chemical & Petrochemical – Regulates complex chemical reactions with safe interlocks.

Food & Beverage – Offers temperature and recipe control in production lines.

Environmental Chambers – Multi-zone temperature and humidity control.

Product Advantages

Scalable Architecture: Supports small to large systems with modular expansion.

Integrated Safety & Process Control: Ideal for combined control and safety applications.

Fast Execution Time: Real-time control with high-speed scan performance.

Flexible Networking: Dual Ethernet ports and RS-485 for peer and supervisory integration.

Modbus Compatibility: Seamless communication with third-party HMIs and SCADA systems.

Rugged and Reliable: Designed for industrial environments with high reliability.

Redundancy Ready: Optional CPU and power module redundancy increase uptime.

Easy Programming: Uses Honeywell’s Hybrid Control Designer software for intuitive configuration.

Multi-Language Support: Offers development environment in multiple international languages.

Regulatory Compliance: Meets global industrial certifications and standards.

Frequently Asked Questions (FAQ)

Q: What is the primary function of the 900C52-0243-00 CPU?

A: It acts as the central processor for the HC900 controller, executing control strategies and managing communications and I/O.

Q: Does the C50 CPU support redundancy?

A: Yes, the HC900 C50 CPU supports optional CPU and power module redundancy for high availability systems.

Q: Which software is used to program the C50 controller?

A: Honeywell Hybrid Control Designer (HCD) is the programming environment for HC900 series CPUs.

Q: Can the CPU communicate with SCADA systems?

A: Yes, it supports Modbus TCP/IP and RTU protocols, enabling integration with SCADA, DCS, and HMI systems.

Q: What is the max number of I/O points supported?

A: The C50 can support up to 4,000 I/O points.

Q: Is it suitable for temperature control in industrial furnaces?

A: Absolutely. It is widely used for temperature and thermal profile control in heat treating and thermal processing.

Q: What communication ports are available?

A: Two Ethernet ports (10/100Base-T) and one RS-485 port.

Q: Can it be DIN rail mounted?

A: Yes, the controller supports both DIN rail and panel mounting.

Q: What type of power does it require?

A: The controller operates on 24 VDC via a separate power module.

Q: Is the controller certified for hazardous areas?

A: Yes, select models are approved for Class I Div 2 environments.

Honeywell 900C52-0243-00 HC900 C50 Controller CPU

Manufacturer:Honeywell

Product Number:900C52-0243-00

Product Type:HC900 C50 Controller CPU

Origin:USA

Dimensions:114 x 176 x 114 mm

Weight:0.13 kg

Views:43

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell 900C52-0243-00 is the HC900 C50 Controller CPU, part of the Honeywell HC900 Hybrid Controller series, designed for process control and safety applications across various industries. It integrates control, data acquisition, and communication functionalities into a scalable and robust platform.

Built for mid-range and high-performance applications, the C50 CPU supports analog and digital I/O modules, advanced control strategies, peer-to-peer communications, and redundancy features. It is widely used in critical sectors such as chemical, pharmaceutical, thermal processing, and water treatment facilities, where reliable and deterministic control is essential.

The HC900 C50 CPU seamlessly communicates with HMIs, SCADA systems, and peer controllers, ensuring centralized and distributed control. Its robust real-time operating system ensures consistent control even in harsh environments.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | 900C52-0243-00 |

| Product Name | HC900 C50 Controller CPU |

| System Type | Hybrid Controller |

| CPU Performance Class | C50 |

| Memory | 1 MB user memory (non-volatile); 32 KB battery-backed RAM |

| Execution Speed | 25 ms scan rate for 500 I/O points |

| Redundancy | Optional CPU and power redundancy |

| Communication Ports | 2 Ethernet 10/100Base-T ports (Modbus TCP, peer-to-peer, HMI) |

| 1 RS-485 serial port (Modbus RTU Slave) | |

| Modbus Support | Modbus RTU (slave), Modbus TCP/IP (master/slave) |

| Max I/O Capacity | Up to 4,000 I/O points |

| Control Loops | Supports up to 100 PID loops |

| Programming Software | Honeywell Hybrid Control Designer (HCD) |

| Mounting | DIN rail or panel mount |

| Power Supply | 24 VDC (via separate power module) |

| Operating Temperature | 0°C to +60°C (32°F to 140°F) |

| Storage Temperature | –40°C to +85°C (–40°F to 185°F) |

| Dimensions (H × W × D) | 114 x 176 x 114 mm |

| Weight | 0.13 kg |

| Certifications | CE, UL, CSA, RoHS, FM, Class I Div 2 approval (select models) |

Applications

The Honeywell HC900 C50 Controller CPU is designed for mid-sized industrial applications requiring precision, flexibility, and robust integration. Common applications include:

Thermal Processing – Batch ovens, kilns, heat treat furnaces, autoclaves.

Water & Wastewater Treatment – Process logic and flow control for treatment plants.

Pharmaceutical Manufacturing – Supports batch control and recipe-based processing.

Chemical & Petrochemical – Regulates complex chemical reactions with safe interlocks.

Food & Beverage – Offers temperature and recipe control in production lines.

Environmental Chambers – Multi-zone temperature and humidity control.

Product Advantages

Scalable Architecture: Supports small to large systems with modular expansion.

Integrated Safety & Process Control: Ideal for combined control and safety applications.

Fast Execution Time: Real-time control with high-speed scan performance.

Flexible Networking: Dual Ethernet ports and RS-485 for peer and supervisory integration.

Modbus Compatibility: Seamless communication with third-party HMIs and SCADA systems.

Rugged and Reliable: Designed for industrial environments with high reliability.

Redundancy Ready: Optional CPU and power module redundancy increase uptime.

Easy Programming: Uses Honeywell’s Hybrid Control Designer software for intuitive configuration.

Multi-Language Support: Offers development environment in multiple international languages.

Regulatory Compliance: Meets global industrial certifications and standards.

Frequently Asked Questions (FAQ)

Q: What is the primary function of the 900C52-0243-00 CPU?

A: It acts as the central processor for the HC900 controller, executing control strategies and managing communications and I/O.

Q: Does the C50 CPU support redundancy?

A: Yes, the HC900 C50 CPU supports optional CPU and power module redundancy for high availability systems.

Q: Which software is used to program the C50 controller?

A: Honeywell Hybrid Control Designer (HCD) is the programming environment for HC900 series CPUs.

Q: Can the CPU communicate with SCADA systems?

A: Yes, it supports Modbus TCP/IP and RTU protocols, enabling integration with SCADA, DCS, and HMI systems.

Q: What is the max number of I/O points supported?

A: The C50 can support up to 4,000 I/O points.

Q: Is it suitable for temperature control in industrial furnaces?

A: Absolutely. It is widely used for temperature and thermal profile control in heat treating and thermal processing.

Q: What communication ports are available?

A: Two Ethernet ports (10/100Base-T) and one RS-485 port.

Q: Can it be DIN rail mounted?

A: Yes, the controller supports both DIN rail and panel mounting.

Q: What type of power does it require?

A: The controller operates on 24 VDC via a separate power module.

Q: Is the controller certified for hazardous areas?

A: Yes, select models are approved for Class I Div 2 environments.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...