Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

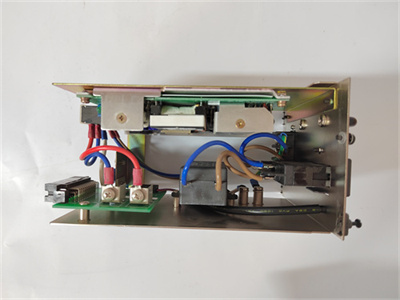

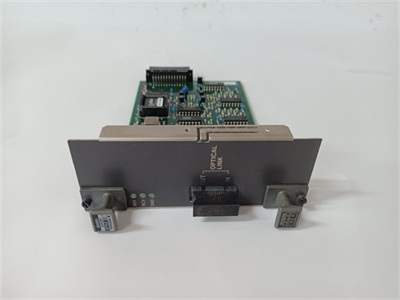

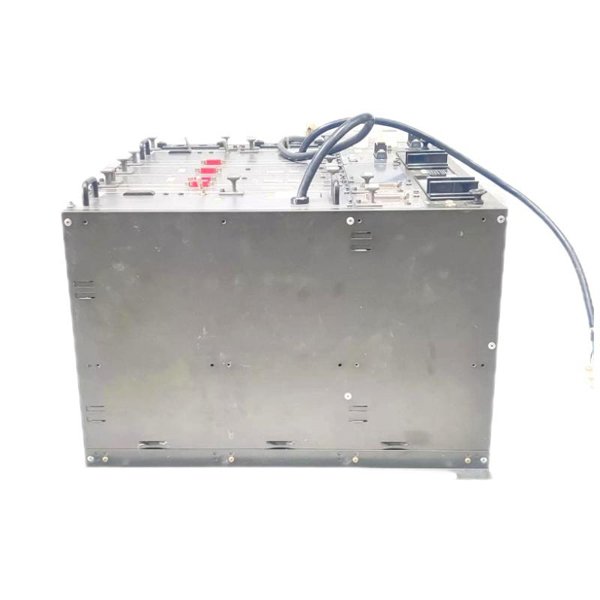

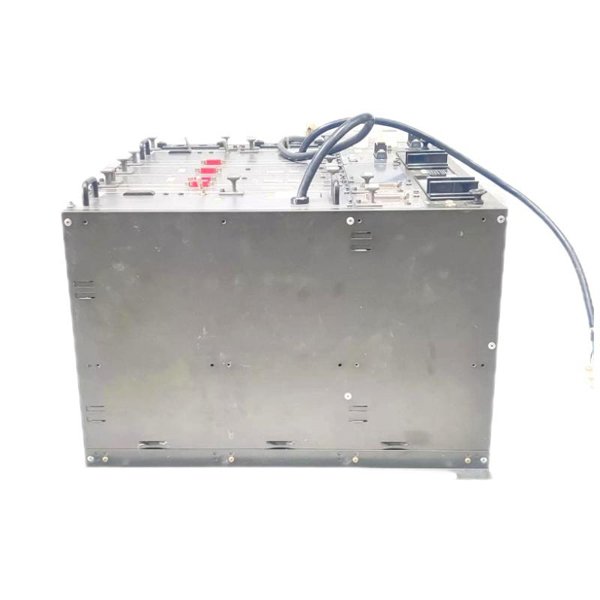

Yokogawa AFG30D Duplex Field Control Unit

Manufacturer:Yokogawa

Product Number:AFG30D

Product Type:Duplex Field Control Unit

Origin:Japan

Dimensions:207 × 265.9 x 482.6 mm

Weight:8kg

Views:58

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa AFG30D Duplex Field Control Unit is a highly advanced and versatile control system designed for use in industrial automation applications. With its state-of-the-art features and cutting-edge technology, the AFG30D is engineered to provide precise and reliable control of field devices in real-time, ensuring seamless integration and enhanced performance. The unit’s duplex design offers both redundancy and improved fault tolerance, making it ideal for mission-critical applications where reliability and uptime are paramount.

The AFG30D is optimized for harsh industrial environments, including industries such as oil and gas, chemical processing, energy generation, and manufacturing. This system supports a wide range of communication protocols, enabling it to be easily integrated with various other systems, sensors, and devices, ensuring maximum operational efficiency.

The unit’s advanced capabilities allow for real-time monitoring and control, improving decision-making and optimizing the overall performance of processes. Whether used in distributed control systems (DCS) or supervisory control systems (SCADA), the AFG30D delivers exceptional performance, ensuring safety, reliability, and efficient operation of automated processes.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | AFG30D |

| Dimensions (WxHxD) | 207 x 265.9 x 482.6 mm |

| Weight | 8 kg |

| Control Type | Duplex (Redundant) |

| Output Channels | 8 channels |

| Power Supply | 24V DC |

| Communication Protocol | Modbus, HART, Fieldbus |

| Mounting | Rack-mounted |

| Temperature Range | -20°C to +60°C |

| Protection Class | IP20 |

| Response Time | < 10 ms |

| System Compatibility | Yokogawa DCS, SCADA systems |

Product Applications

The Yokogawa AFG30D Duplex Field Control Unit is designed for use in a wide range of industrial automation applications where reliability, redundancy, and high performance are crucial. Some of the primary applications include:

Oil and Gas Industry: The AFG30D is widely used in the oil and gas industry for controlling and monitoring critical field devices such as pumps, valves, and pressure sensors. The duplex design ensures continuous operation even in the event of component failure, providing a fail-safe solution for upstream and downstream processes.

Power Generation: In power generation plants, the AFG30D manages critical control functions related to turbines, generators, and other key assets. The system’s fast response time and redundancy ensure the reliability of power systems, minimizing downtime and enhancing efficiency.

Chemical Processing: The AFG30D is used to control chemical reactors, conveyors, and other vital processes in chemical plants. Its ability to support multiple communication protocols allows seamless integration with other systems for monitoring and control, ensuring safe and efficient chemical production.

Manufacturing Automation: The unit can also be found in automated manufacturing processes, controlling robotics, assembly lines, and material handling systems. The system’s precise control capabilities enhance operational throughput, improving production efficiency and reducing errors.

Water and Wastewater Treatment: In water and wastewater management, the AFG30D plays a vital role in controlling water treatment facilities, pumps, motors, and other critical infrastructure. Its advanced monitoring and control capabilities ensure that water quality standards are met and operations run smoothly.

Food and Beverage Industry: The AFG30D is ideal for controlling processes in the food and beverage industry, including monitoring and controlling bottling lines, sterilization processes, and packaging systems. Its real-time capabilities allow for quick adjustments, ensuring product consistency and quality.

Product Advantages

Redundant Design for High Reliability: The duplex configuration of the AFG30D ensures continuous operation, even if one unit fails. This redundancy is vital for mission-critical applications where downtime is not an option, providing higher fault tolerance and reducing the risk of system failure.

High-Speed Response: With a response time of less than 10 milliseconds, the AFG30D ensures that control signals are transmitted quickly and accurately, minimizing delays in automation processes and improving operational efficiency.

Wide Temperature Range: The AFG30D operates effectively within a wide temperature range of -20°C to +60°C, making it suitable for use in harsh industrial environments, including those with extreme temperatures.

Compact and Robust Design: Despite its advanced functionality, the AFG30D has a compact form factor (207 x 265.9 x 482.6 mm) and a lightweight design, weighing only 8 kg. Its robust construction ensures long-lasting performance in demanding environments.

Seamless Integration with Existing Systems: The AFG30D supports multiple communication protocols such as Modbus, HART, and Fieldbus, allowing it to be easily integrated with existing Yokogawa DCS or SCADA systems, facilitating smooth system expansion and upgrades.

User-Friendly Interface: The system comes with a user-friendly interface for easy setup, configuration, and maintenance. This ease of use reduces the complexity of installation and ensures smooth operation over time.

FAQ

Q1: What is the weight of the AFG30D?

A1: The AFG30D weighs 8 kg, making it compact and easy to integrate into existing systems.

Q2: What is the response time of the AFG30D?

A2: The response time of the AFG30D is less than 10 milliseconds, ensuring fast control and communication.

Q3: How many output channels does the AFG30D have?

A3: The AFG30D has 8 output channels, enabling it to control multiple devices simultaneously.

Q4: Can the AFG30D be integrated with other Yokogawa systems?

A4: Yes, the AFG30D is fully compatible with Yokogawa’s DCS and SCADA systems, ensuring seamless integration.

Q5: What temperature range can the AFG30D operate in?

A5: The AFG30D operates within a temperature range of -20°C to +60°C, making it suitable for a wide variety of industrial environments.

Q6: What is the power supply for the AFG30D?

A6: The AFG30D operates on a 24V DC power supply.

Q7: What are the communication protocols supported by the AFG30D?

A7: The AFG30D supports Modbus, HART, and Fieldbus communication protocols, allowing for versatile integration with other devices.

Q8: What industries benefit most from the AFG30D?

A8: The AFG30D is ideal for industries such as oil and gas, power generation, chemical processing, manufacturing automation, and water treatment.

Q9: How does the duplex design benefit the AFG30D?

A9: The duplex design offers redundancy, ensuring continuous operation even if one unit fails. This provides enhanced reliability and minimizes downtime.

Q10: Can the AFG30D be rack-mounted?

A10: Yes, the AFG30D is designed to be rack-mounted, providing flexibility for installation in various setups.

Yokogawa AFG30D Duplex Field Control Unit

Manufacturer:Yokogawa

Product Number:AFG30D

Product Type:Duplex Field Control Unit

Origin:Japan

Dimensions:207 × 265.9 x 482.6 mm

Weight:8kg

Views:58

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa AFG30D Duplex Field Control Unit is a highly advanced and versatile control system designed for use in industrial automation applications. With its state-of-the-art features and cutting-edge technology, the AFG30D is engineered to provide precise and reliable control of field devices in real-time, ensuring seamless integration and enhanced performance. The unit’s duplex design offers both redundancy and improved fault tolerance, making it ideal for mission-critical applications where reliability and uptime are paramount.

The AFG30D is optimized for harsh industrial environments, including industries such as oil and gas, chemical processing, energy generation, and manufacturing. This system supports a wide range of communication protocols, enabling it to be easily integrated with various other systems, sensors, and devices, ensuring maximum operational efficiency.

The unit’s advanced capabilities allow for real-time monitoring and control, improving decision-making and optimizing the overall performance of processes. Whether used in distributed control systems (DCS) or supervisory control systems (SCADA), the AFG30D delivers exceptional performance, ensuring safety, reliability, and efficient operation of automated processes.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | AFG30D |

| Dimensions (WxHxD) | 207 x 265.9 x 482.6 mm |

| Weight | 8 kg |

| Control Type | Duplex (Redundant) |

| Output Channels | 8 channels |

| Power Supply | 24V DC |

| Communication Protocol | Modbus, HART, Fieldbus |

| Mounting | Rack-mounted |

| Temperature Range | -20°C to +60°C |

| Protection Class | IP20 |

| Response Time | < 10 ms |

| System Compatibility | Yokogawa DCS, SCADA systems |

Product Applications

The Yokogawa AFG30D Duplex Field Control Unit is designed for use in a wide range of industrial automation applications where reliability, redundancy, and high performance are crucial. Some of the primary applications include:

Oil and Gas Industry: The AFG30D is widely used in the oil and gas industry for controlling and monitoring critical field devices such as pumps, valves, and pressure sensors. The duplex design ensures continuous operation even in the event of component failure, providing a fail-safe solution for upstream and downstream processes.

Power Generation: In power generation plants, the AFG30D manages critical control functions related to turbines, generators, and other key assets. The system’s fast response time and redundancy ensure the reliability of power systems, minimizing downtime and enhancing efficiency.

Chemical Processing: The AFG30D is used to control chemical reactors, conveyors, and other vital processes in chemical plants. Its ability to support multiple communication protocols allows seamless integration with other systems for monitoring and control, ensuring safe and efficient chemical production.

Manufacturing Automation: The unit can also be found in automated manufacturing processes, controlling robotics, assembly lines, and material handling systems. The system’s precise control capabilities enhance operational throughput, improving production efficiency and reducing errors.

Water and Wastewater Treatment: In water and wastewater management, the AFG30D plays a vital role in controlling water treatment facilities, pumps, motors, and other critical infrastructure. Its advanced monitoring and control capabilities ensure that water quality standards are met and operations run smoothly.

Food and Beverage Industry: The AFG30D is ideal for controlling processes in the food and beverage industry, including monitoring and controlling bottling lines, sterilization processes, and packaging systems. Its real-time capabilities allow for quick adjustments, ensuring product consistency and quality.

Product Advantages

Redundant Design for High Reliability: The duplex configuration of the AFG30D ensures continuous operation, even if one unit fails. This redundancy is vital for mission-critical applications where downtime is not an option, providing higher fault tolerance and reducing the risk of system failure.

High-Speed Response: With a response time of less than 10 milliseconds, the AFG30D ensures that control signals are transmitted quickly and accurately, minimizing delays in automation processes and improving operational efficiency.

Wide Temperature Range: The AFG30D operates effectively within a wide temperature range of -20°C to +60°C, making it suitable for use in harsh industrial environments, including those with extreme temperatures.

Compact and Robust Design: Despite its advanced functionality, the AFG30D has a compact form factor (207 x 265.9 x 482.6 mm) and a lightweight design, weighing only 8 kg. Its robust construction ensures long-lasting performance in demanding environments.

Seamless Integration with Existing Systems: The AFG30D supports multiple communication protocols such as Modbus, HART, and Fieldbus, allowing it to be easily integrated with existing Yokogawa DCS or SCADA systems, facilitating smooth system expansion and upgrades.

User-Friendly Interface: The system comes with a user-friendly interface for easy setup, configuration, and maintenance. This ease of use reduces the complexity of installation and ensures smooth operation over time.

FAQ

Q1: What is the weight of the AFG30D?

A1: The AFG30D weighs 8 kg, making it compact and easy to integrate into existing systems.

Q2: What is the response time of the AFG30D?

A2: The response time of the AFG30D is less than 10 milliseconds, ensuring fast control and communication.

Q3: How many output channels does the AFG30D have?

A3: The AFG30D has 8 output channels, enabling it to control multiple devices simultaneously.

Q4: Can the AFG30D be integrated with other Yokogawa systems?

A4: Yes, the AFG30D is fully compatible with Yokogawa’s DCS and SCADA systems, ensuring seamless integration.

Q5: What temperature range can the AFG30D operate in?

A5: The AFG30D operates within a temperature range of -20°C to +60°C, making it suitable for a wide variety of industrial environments.

Q6: What is the power supply for the AFG30D?

A6: The AFG30D operates on a 24V DC power supply.

Q7: What are the communication protocols supported by the AFG30D?

A7: The AFG30D supports Modbus, HART, and Fieldbus communication protocols, allowing for versatile integration with other devices.

Q8: What industries benefit most from the AFG30D?

A8: The AFG30D is ideal for industries such as oil and gas, power generation, chemical processing, manufacturing automation, and water treatment.

Q9: How does the duplex design benefit the AFG30D?

A9: The duplex design offers redundancy, ensuring continuous operation even if one unit fails. This provides enhanced reliability and minimizes downtime.

Q10: Can the AFG30D be rack-mounted?

A10: Yes, the AFG30D is designed to be rack-mounted, providing flexibility for installation in various setups.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...