Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

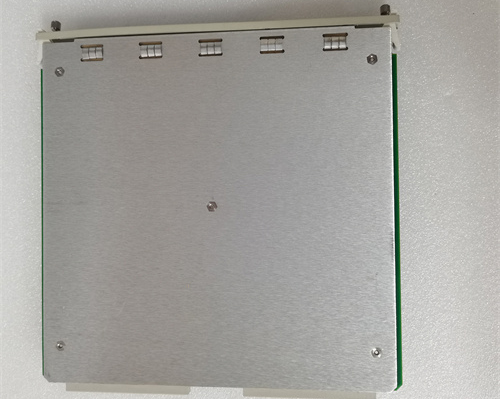

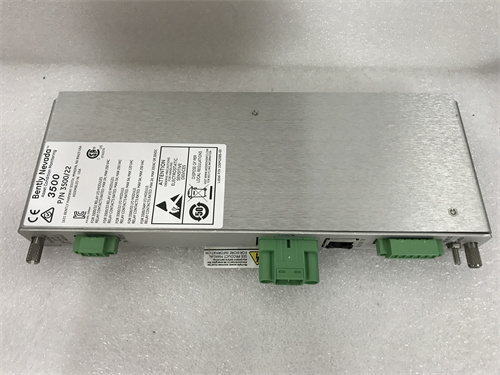

Bently Nevada 3500/22 288055-01 Transient Data Interface Module

Manufacturer:Bently Nevada

Product Number:3500/22 288055-01

Product Type:Transient Data Interface Module

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91 kg

Views:37

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/22 288055-01 Transient Data Interface Module (TDI) is a core communication and data acquisition module used in the Bently Nevada 3500 Machinery Protection System.

It combines the functionality of the 3500/20 Rack Interface Module (RIM) with advanced communication processing, providing a streamlined solution for transmitting static and transient machinery data to external software platforms such as System 1 Condition Monitoring.

Installed exclusively in Slot 1 of the rack, adjacent to the power supply module, the 288055-01 TDI collects input from all rack monitoring modules, consolidates this data, and transmits it over Ethernet or fiber-optic connections.

When used with an optional Channel Enabling Disk, it enables high-resolution transient waveform capture for in-depth diagnostic evaluation of machinery events such as startups, shutdowns, and trip conditions.

The 3500/22 288055-01 is widely recognized for its robust design, ease of integration, and ability to handle high-speed data communication without impacting the protection functions of the system.

Product Parameters

| Parameter | Specification |

|---|---|

| Part Number | 288055-01 |

| Series | Bently Nevada 3500 |

| Module Type | Transient Data Interface Module |

| Slot Position | Slot 1 (next to rack power supply) |

| Power Consumption | Approx. 10.5 W |

| Input Signal Range | –10 V DC to +10 V DC |

| Ethernet Interface | 10Base-T / 100Base-TX (copper) or 100Base-FX (fiber) |

| Operating Temperature | –30 °C to +65 °C |

| Storage Temperature | –40 °C to +85 °C |

| Relative Humidity | 0% to 95% non-condensing |

| Front Panel Interface | USB-B port |

| Indicators | OK, TX/RX, TM, CONFIG OK LEDs |

| Dimensions (W × H × D) | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

| Mounting | 3500 rack slot |

Product Applications

The 288055-01 TDI is deployed in industrial environments where machinery protection and advanced condition monitoring are critical.

Its applications include:

Real-time machine condition monitoring: Gathering both steady-state values and transient waveform data for analysis.

Predictive maintenance integration: Seamless data transfer to System 1 for continuous health monitoring.

Transient event capture: Detecting and recording startup, coast-down, trip, and load-change events.

TMR (Triple Modular Redundancy) support: Comparing outputs from three redundant monitors for fault voting and isolation.

Secure remote configuration: Allowing remote setup while ensuring protection through hardware keylock security.

Alarm and event correlation: Linking transient waveforms to alarm timestamps for accurate diagnostics.

Product Advantages

Integrated functionality – Combines RIM and communication processor roles, reducing hardware count.

Non-intrusive to protection path – Data communication failures do not compromise the protective trip logic.

Versatile communication – Supports both copper Ethernet and fiber-optic links for flexible deployment.

High-resolution event recording – Captures pre- and post-event transient data with optional enabling disk.

Rugged industrial design – Operates reliably in extended temperature and humidity ranges.

Instant status visibility – LED indicators and OK relay for fast health diagnostics.

Seamless integration – Designed for compatibility with M-series monitors and 3500 rack systems.

FAQ

What functions does the TDI provide compared to a standard RIM?

It adds communication processing and transient data capture capabilities to the RIM’s basic rack interface role.

Can the 288055-01 TDI be used without an enabling disk?

Yes, but only static data will be transmitted—transient waveform capture requires the disk.

How does the module handle redundant system configurations?

In TMR systems, it compares readings from three redundant monitors and flags inconsistencies for voting logic.

What networking standards does it support?

It supports 10Base-T / 100Base-TX copper Ethernet and 100Base-FX fiber-optic connections.

Does it process all rack data channels?

Yes, it aggregates inputs from all installed monitor and I/O modules in the rack.

How are transient events triggered?

Through alarms, speed windows, or operator-initiated capture via System 1 or configuration software.

What happens if the TDI fails?

Data transmission may stop, but protective functions remain intact as it is not part of the trip chain.

Can it be configured remotely?

Yes, provided the rack is in PROGRAM mode; RUN mode locks configuration changes.

Is the front USB port required for normal operation?

No, it is used mainly for direct configuration and diagnostics, not routine communication.

What LED indicators are provided?

OK (module health), TX/RX (network traffic), TM (trip multiply), CONFIG OK (valid configuration).

Bently Nevada 3500/22 288055-01 Transient Data Interface Module

Manufacturer:Bently Nevada

Product Number:3500/22 288055-01

Product Type:Transient Data Interface Module

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91 kg

Views:37

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/22 288055-01 Transient Data Interface Module (TDI) is a core communication and data acquisition module used in the Bently Nevada 3500 Machinery Protection System.

It combines the functionality of the 3500/20 Rack Interface Module (RIM) with advanced communication processing, providing a streamlined solution for transmitting static and transient machinery data to external software platforms such as System 1 Condition Monitoring.

Installed exclusively in Slot 1 of the rack, adjacent to the power supply module, the 288055-01 TDI collects input from all rack monitoring modules, consolidates this data, and transmits it over Ethernet or fiber-optic connections.

When used with an optional Channel Enabling Disk, it enables high-resolution transient waveform capture for in-depth diagnostic evaluation of machinery events such as startups, shutdowns, and trip conditions.

The 3500/22 288055-01 is widely recognized for its robust design, ease of integration, and ability to handle high-speed data communication without impacting the protection functions of the system.

Product Parameters

| Parameter | Specification |

|---|---|

| Part Number | 288055-01 |

| Series | Bently Nevada 3500 |

| Module Type | Transient Data Interface Module |

| Slot Position | Slot 1 (next to rack power supply) |

| Power Consumption | Approx. 10.5 W |

| Input Signal Range | –10 V DC to +10 V DC |

| Ethernet Interface | 10Base-T / 100Base-TX (copper) or 100Base-FX (fiber) |

| Operating Temperature | –30 °C to +65 °C |

| Storage Temperature | –40 °C to +85 °C |

| Relative Humidity | 0% to 95% non-condensing |

| Front Panel Interface | USB-B port |

| Indicators | OK, TX/RX, TM, CONFIG OK LEDs |

| Dimensions (W × H × D) | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

| Mounting | 3500 rack slot |

Product Applications

The 288055-01 TDI is deployed in industrial environments where machinery protection and advanced condition monitoring are critical.

Its applications include:

Real-time machine condition monitoring: Gathering both steady-state values and transient waveform data for analysis.

Predictive maintenance integration: Seamless data transfer to System 1 for continuous health monitoring.

Transient event capture: Detecting and recording startup, coast-down, trip, and load-change events.

TMR (Triple Modular Redundancy) support: Comparing outputs from three redundant monitors for fault voting and isolation.

Secure remote configuration: Allowing remote setup while ensuring protection through hardware keylock security.

Alarm and event correlation: Linking transient waveforms to alarm timestamps for accurate diagnostics.

Product Advantages

Integrated functionality – Combines RIM and communication processor roles, reducing hardware count.

Non-intrusive to protection path – Data communication failures do not compromise the protective trip logic.

Versatile communication – Supports both copper Ethernet and fiber-optic links for flexible deployment.

High-resolution event recording – Captures pre- and post-event transient data with optional enabling disk.

Rugged industrial design – Operates reliably in extended temperature and humidity ranges.

Instant status visibility – LED indicators and OK relay for fast health diagnostics.

Seamless integration – Designed for compatibility with M-series monitors and 3500 rack systems.

FAQ

What functions does the TDI provide compared to a standard RIM?

It adds communication processing and transient data capture capabilities to the RIM’s basic rack interface role.

Can the 288055-01 TDI be used without an enabling disk?

Yes, but only static data will be transmitted—transient waveform capture requires the disk.

How does the module handle redundant system configurations?

In TMR systems, it compares readings from three redundant monitors and flags inconsistencies for voting logic.

What networking standards does it support?

It supports 10Base-T / 100Base-TX copper Ethernet and 100Base-FX fiber-optic connections.

Does it process all rack data channels?

Yes, it aggregates inputs from all installed monitor and I/O modules in the rack.

How are transient events triggered?

Through alarms, speed windows, or operator-initiated capture via System 1 or configuration software.

What happens if the TDI fails?

Data transmission may stop, but protective functions remain intact as it is not part of the trip chain.

Can it be configured remotely?

Yes, provided the rack is in PROGRAM mode; RUN mode locks configuration changes.

Is the front USB port required for normal operation?

No, it is used mainly for direct configuration and diagnostics, not routine communication.

What LED indicators are provided?

OK (module health), TX/RX (network traffic), TM (trip multiply), CONFIG OK (valid configuration).

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...