Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

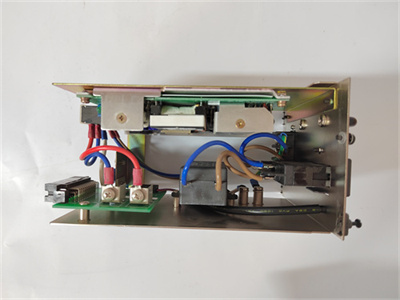

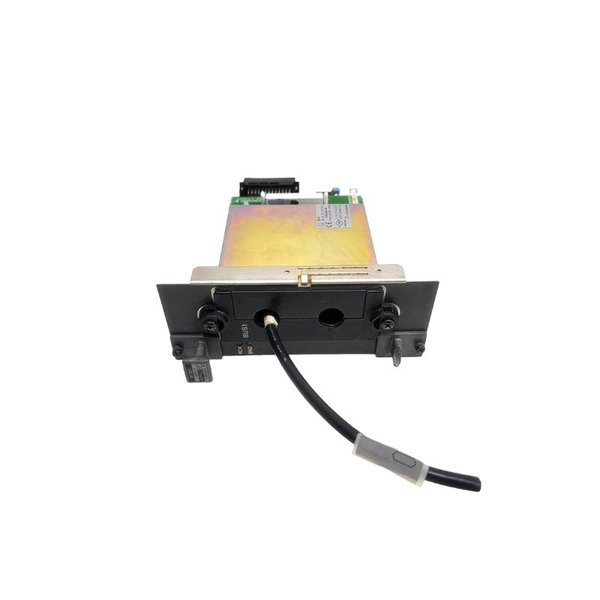

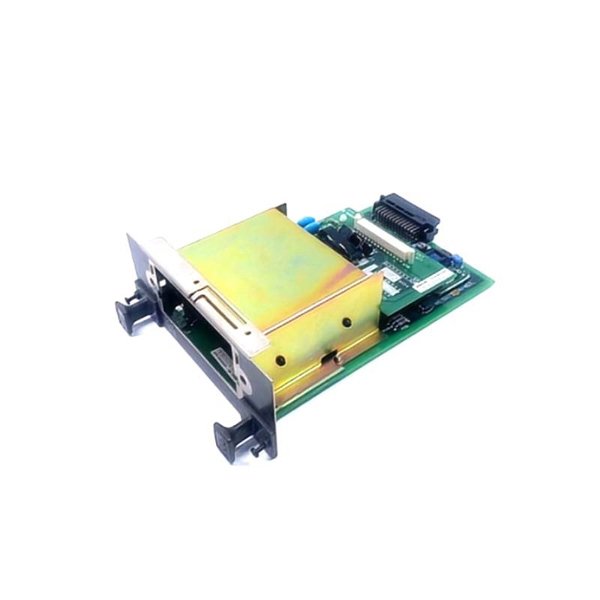

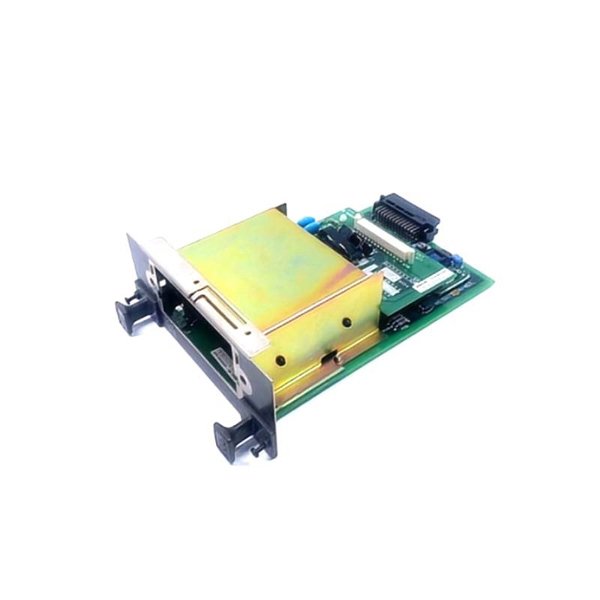

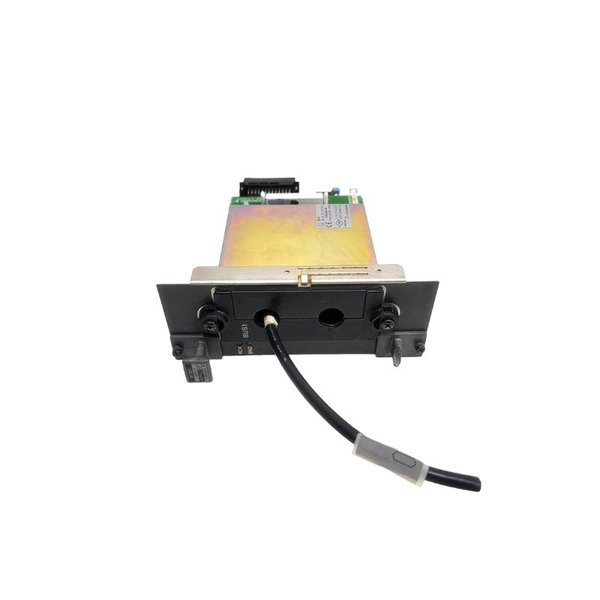

Yokogawa AIP571 Electrical Transceiver RIO I/O Module

Manufacturer:Yokogawa

Product Number:AIP571

Product Type:Electrical Transceiver RIO I/O Module

Origin:Japan

Dimensions:150 x 120 x 50 mm

Weight:0.408kg

Views:50

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa AIP571 Electrical Transceiver RIO I/O Module is an advanced solution designed for industrial automation systems. It facilitates communication between various field devices and controllers using the Remote Input/Output (RIO) communication protocol. This module serves as a critical component for the seamless integration of field devices into distributed control systems (DCS) or supervisory control systems (SCADA), providing real-time data acquisition and monitoring capabilities.

The AIP571 is equipped with advanced features that ensure high reliability, fault tolerance, and robust performance in industrial environments. Whether used for process control, asset management, or system monitoring, the AIP571 ensures accurate and timely data transmission between field devices and control systems. This module is suitable for industries such as manufacturing, energy generation, chemical processing, and water treatment, where precision and reliability are paramount.

The module’s design allows for easy integration into existing Yokogawa systems, with user-friendly configuration and maintenance processes. It supports a variety of communication protocols, making it compatible with other industrial automation systems and ensuring a high level of flexibility for system expansions and upgrades.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | AIP571 |

| Dimensions (WxHxD) | 150 x 120 x 50 mm |

| Weight | 0.408 kg |

| Input/Output Channels | 8 channels |

| Power Supply | 24V DC |

| Communication Protocol | RIO, Modbus, HART |

| Mounting | DIN rail or panel mount |

| Temperature Range | -20°C to +60°C |

| Protection Class | IP20 |

| Data Rate | 1 Mbps |

| Operating Humidity | 5% to 95% (non-condensing) |

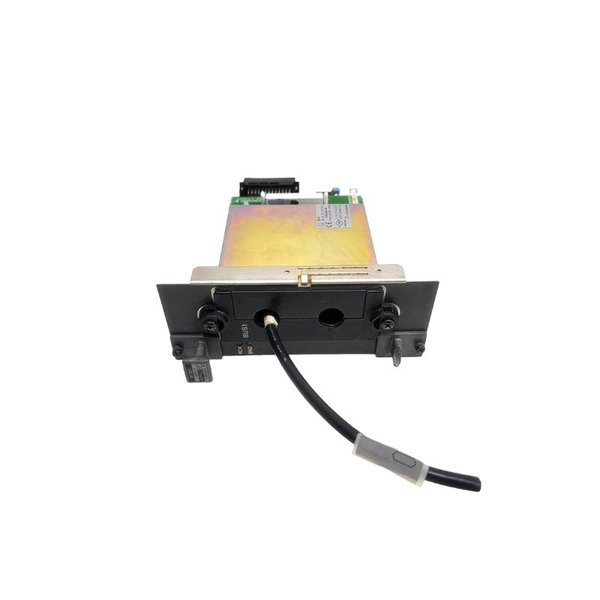

| Interface Ports | 2 ports (for field communication) |

Product Applications

The Yokogawa AIP571 Electrical Transceiver RIO I/O Module is designed to address communication and data acquisition needs in various industrial environments. Some of the key applications of the AIP571 include:

Manufacturing Automation: The AIP571 enables seamless communication between field devices, sensors, and controllers in automated manufacturing processes. It allows for real-time monitoring and control of machinery, production lines, and robotic systems, ensuring optimal operational efficiency and reducing downtime.

Oil & Gas: In the oil and gas industry, the AIP571 is used to monitor and control vital equipment such as pumps, compressors, and valves. The module’s compatibility with multiple communication protocols ensures reliable data transfer and system integration across various devices used in upstream, midstream, and downstream processes.

Energy Generation: The AIP571 plays a critical role in power plants and renewable energy installations. It facilitates data collection from turbines, generators, and other power generation equipment, providing real-time insights for efficient asset management and process optimization.

Chemical Processing: In chemical plants, the AIP571 connects various sensors, actuators, and control devices, ensuring accurate data transmission for controlling temperature, pressure, and chemical composition. This enhances process control and reduces the risk of errors or system failures.

Water and Wastewater Treatment: The module is used in water treatment plants to monitor and control various parameters such as water flow, pressure, and filtration. Its real-time data collection capability allows operators to optimize treatment processes and ensure compliance with regulatory standards.

Building Management Systems (BMS): The AIP571 integrates various building systems, including HVAC, lighting, and energy management. It ensures that the building’s systems work together efficiently, optimizing energy usage and improving overall building performance.

Product Advantages

Flexible Communication Protocols: The AIP571 supports multiple communication protocols, including RIO, Modbus, and HART. This enables easy integration with various industrial control systems and devices, making it an ideal choice for diverse applications.

Compact and Robust Design: With dimensions of 150 x 120 x 50 mm and a weight of 0.408 kg, the AIP571 is compact and lightweight, making it easy to install in tight spaces. Its rugged design ensures reliable performance in harsh industrial environments.

High Data Rate: The AIP571 supports a data rate of up to 1 Mbps, ensuring fast and reliable data transmission between field devices and control systems. This is critical for real-time process monitoring and control in dynamic industrial settings.

Redundant Communication Ports: The AIP571 is equipped with two communication ports, providing redundancy for reliable data transfer and minimizing the risk of communication failures.

Wide Temperature Range: The module can operate in a wide temperature range of -20°C to +60°C, making it suitable for use in a variety of industrial environments, from cold storage facilities to high-temperature processing plants.

Ease of Integration: Designed for easy integration into existing Yokogawa systems, the AIP571 simplifies system upgrades and expansions. Its support for common communication protocols ensures compatibility with a wide range of devices and systems.

High Reliability: The AIP571 is engineered for high reliability and fault tolerance, ensuring continuous operation in mission-critical applications. Its robust protection class (IP20) provides protection against dust and environmental factors.

FAQ

Q1: What is the communication protocol supported by the AIP571?

A1: The AIP571 supports multiple communication protocols, including RIO, Modbus, and HART, ensuring flexibility in system integration.

Q2: How many input/output channels does the AIP571 have?

A2: The AIP571 has 8 input/output channels, allowing it to handle multiple field devices simultaneously.

Q3: What is the weight of the AIP571?

A3: The AIP571 weighs 0.408 kg, making it lightweight and easy to install.

Q4: What is the power supply requirement for the AIP571?

A4: The AIP571 requires a 24V DC power supply for operation.

Q5: What is the temperature range of the AIP571?

A5: The AIP571 operates within a temperature range of -20°C to +60°C, making it suitable for a wide range of industrial environments.

Q6: Can the AIP571 be mounted on a DIN rail?

A6: Yes, the AIP571 can be mounted on a DIN rail or panel-mounted, offering flexibility in installation.

Q7: What is the data rate of the AIP571?

A7: The AIP571 supports a data rate of up to 1 Mbps, ensuring fast and reliable data transmission.

Q8: What industries can benefit from the AIP571?

A8: The AIP571 is ideal for industries such as manufacturing, oil and gas, energy generation, chemical processing, water treatment, and building management.

Q9: Is the AIP571 compatible with other Yokogawa systems?

A9: Yes, the AIP571 is designed to integrate seamlessly with other Yokogawa DCS and SCADA systems.

Q10: What is the protection class of the AIP571?

A10: The AIP571 has an IP20 protection class, providing protection against dust and environmental factors.

Yokogawa AIP571 Electrical Transceiver RIO I/O Module

Manufacturer:Yokogawa

Product Number:AIP571

Product Type:Electrical Transceiver RIO I/O Module

Origin:Japan

Dimensions:150 x 120 x 50 mm

Weight:0.408kg

Views:50

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa AIP571 Electrical Transceiver RIO I/O Module is an advanced solution designed for industrial automation systems. It facilitates communication between various field devices and controllers using the Remote Input/Output (RIO) communication protocol. This module serves as a critical component for the seamless integration of field devices into distributed control systems (DCS) or supervisory control systems (SCADA), providing real-time data acquisition and monitoring capabilities.

The AIP571 is equipped with advanced features that ensure high reliability, fault tolerance, and robust performance in industrial environments. Whether used for process control, asset management, or system monitoring, the AIP571 ensures accurate and timely data transmission between field devices and control systems. This module is suitable for industries such as manufacturing, energy generation, chemical processing, and water treatment, where precision and reliability are paramount.

The module’s design allows for easy integration into existing Yokogawa systems, with user-friendly configuration and maintenance processes. It supports a variety of communication protocols, making it compatible with other industrial automation systems and ensuring a high level of flexibility for system expansions and upgrades.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | AIP571 |

| Dimensions (WxHxD) | 150 x 120 x 50 mm |

| Weight | 0.408 kg |

| Input/Output Channels | 8 channels |

| Power Supply | 24V DC |

| Communication Protocol | RIO, Modbus, HART |

| Mounting | DIN rail or panel mount |

| Temperature Range | -20°C to +60°C |

| Protection Class | IP20 |

| Data Rate | 1 Mbps |

| Operating Humidity | 5% to 95% (non-condensing) |

| Interface Ports | 2 ports (for field communication) |

Product Applications

The Yokogawa AIP571 Electrical Transceiver RIO I/O Module is designed to address communication and data acquisition needs in various industrial environments. Some of the key applications of the AIP571 include:

Manufacturing Automation: The AIP571 enables seamless communication between field devices, sensors, and controllers in automated manufacturing processes. It allows for real-time monitoring and control of machinery, production lines, and robotic systems, ensuring optimal operational efficiency and reducing downtime.

Oil & Gas: In the oil and gas industry, the AIP571 is used to monitor and control vital equipment such as pumps, compressors, and valves. The module’s compatibility with multiple communication protocols ensures reliable data transfer and system integration across various devices used in upstream, midstream, and downstream processes.

Energy Generation: The AIP571 plays a critical role in power plants and renewable energy installations. It facilitates data collection from turbines, generators, and other power generation equipment, providing real-time insights for efficient asset management and process optimization.

Chemical Processing: In chemical plants, the AIP571 connects various sensors, actuators, and control devices, ensuring accurate data transmission for controlling temperature, pressure, and chemical composition. This enhances process control and reduces the risk of errors or system failures.

Water and Wastewater Treatment: The module is used in water treatment plants to monitor and control various parameters such as water flow, pressure, and filtration. Its real-time data collection capability allows operators to optimize treatment processes and ensure compliance with regulatory standards.

Building Management Systems (BMS): The AIP571 integrates various building systems, including HVAC, lighting, and energy management. It ensures that the building’s systems work together efficiently, optimizing energy usage and improving overall building performance.

Product Advantages

Flexible Communication Protocols: The AIP571 supports multiple communication protocols, including RIO, Modbus, and HART. This enables easy integration with various industrial control systems and devices, making it an ideal choice for diverse applications.

Compact and Robust Design: With dimensions of 150 x 120 x 50 mm and a weight of 0.408 kg, the AIP571 is compact and lightweight, making it easy to install in tight spaces. Its rugged design ensures reliable performance in harsh industrial environments.

High Data Rate: The AIP571 supports a data rate of up to 1 Mbps, ensuring fast and reliable data transmission between field devices and control systems. This is critical for real-time process monitoring and control in dynamic industrial settings.

Redundant Communication Ports: The AIP571 is equipped with two communication ports, providing redundancy for reliable data transfer and minimizing the risk of communication failures.

Wide Temperature Range: The module can operate in a wide temperature range of -20°C to +60°C, making it suitable for use in a variety of industrial environments, from cold storage facilities to high-temperature processing plants.

Ease of Integration: Designed for easy integration into existing Yokogawa systems, the AIP571 simplifies system upgrades and expansions. Its support for common communication protocols ensures compatibility with a wide range of devices and systems.

High Reliability: The AIP571 is engineered for high reliability and fault tolerance, ensuring continuous operation in mission-critical applications. Its robust protection class (IP20) provides protection against dust and environmental factors.

FAQ

Q1: What is the communication protocol supported by the AIP571?

A1: The AIP571 supports multiple communication protocols, including RIO, Modbus, and HART, ensuring flexibility in system integration.

Q2: How many input/output channels does the AIP571 have?

A2: The AIP571 has 8 input/output channels, allowing it to handle multiple field devices simultaneously.

Q3: What is the weight of the AIP571?

A3: The AIP571 weighs 0.408 kg, making it lightweight and easy to install.

Q4: What is the power supply requirement for the AIP571?

A4: The AIP571 requires a 24V DC power supply for operation.

Q5: What is the temperature range of the AIP571?

A5: The AIP571 operates within a temperature range of -20°C to +60°C, making it suitable for a wide range of industrial environments.

Q6: Can the AIP571 be mounted on a DIN rail?

A6: Yes, the AIP571 can be mounted on a DIN rail or panel-mounted, offering flexibility in installation.

Q7: What is the data rate of the AIP571?

A7: The AIP571 supports a data rate of up to 1 Mbps, ensuring fast and reliable data transmission.

Q8: What industries can benefit from the AIP571?

A8: The AIP571 is ideal for industries such as manufacturing, oil and gas, energy generation, chemical processing, water treatment, and building management.

Q9: Is the AIP571 compatible with other Yokogawa systems?

A9: Yes, the AIP571 is designed to integrate seamlessly with other Yokogawa DCS and SCADA systems.

Q10: What is the protection class of the AIP571?

A10: The AIP571 has an IP20 protection class, providing protection against dust and environmental factors.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...