Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

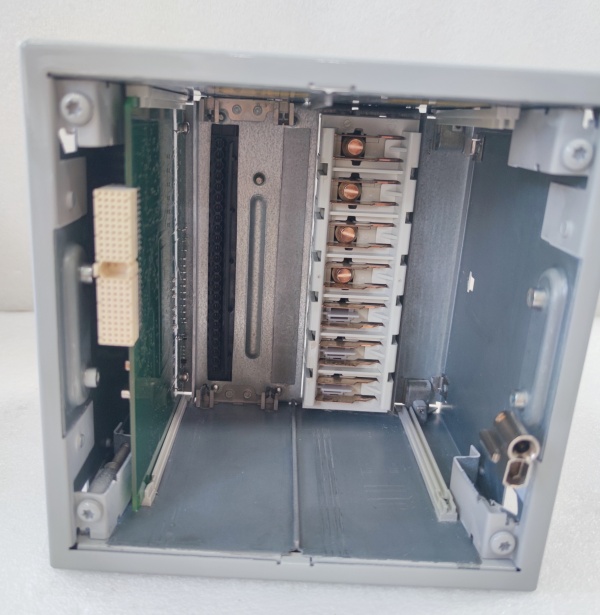

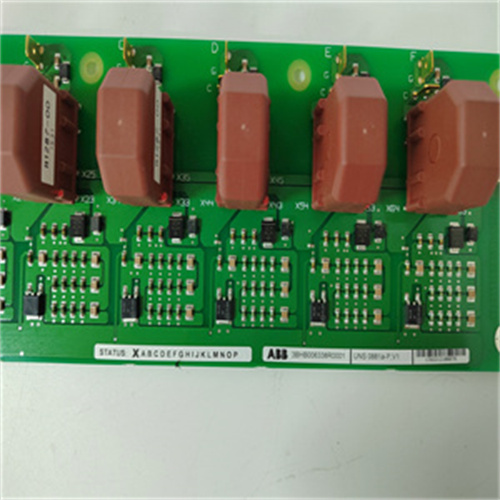

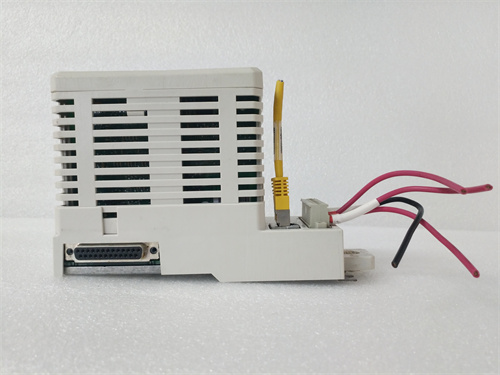

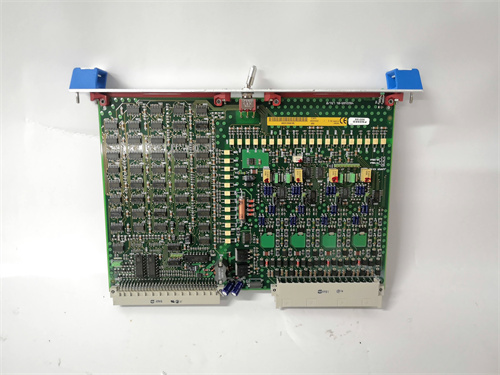

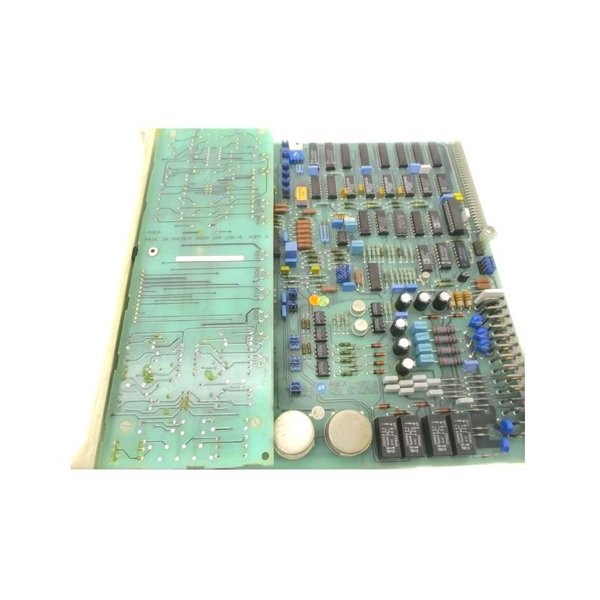

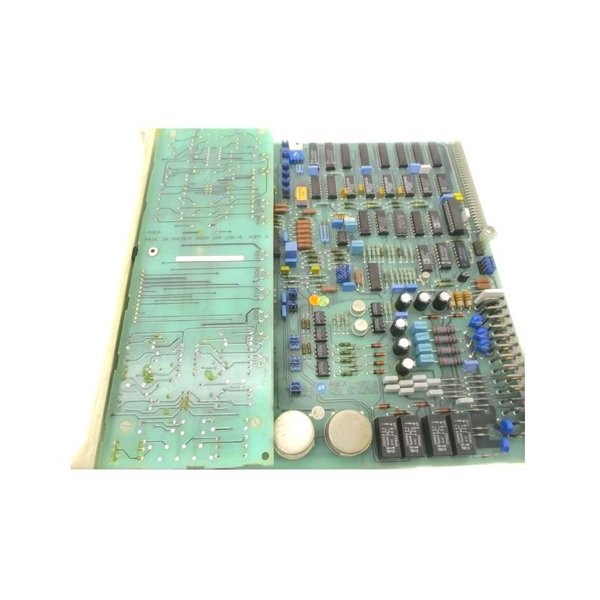

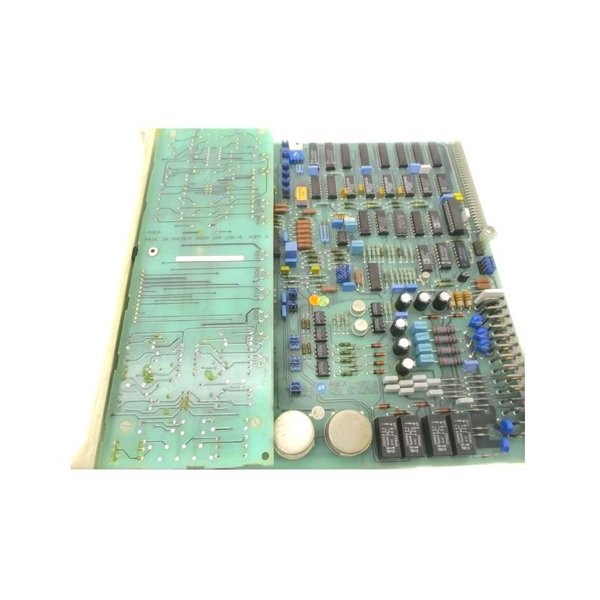

ABB PFUK104 YM110002-SD Processor Board

Manufacturer:ABB

Product Number:PFUK104 YM110002-SD

Product Type:Processor Board

Origin:Sweden

Dimensions:160 × 160 × 120 mm

Weight:0.8 kg

Views:59

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB PFUK104 YM110002-SD is a powerful and reliable processor board designed for use in ABB’s Advant Controller series and integrated process automation systems. It plays a central role in executing control algorithms, handling real-time communication, and facilitating smooth interaction between the controller and field devices in industrial applications.

As a core component of ABB’s modular automation architecture, the PFUK104 provides processing capabilities for time-critical tasks such as signal conditioning, loop control, data acquisition, and inter-module communication. It is especially suitable for complex process control environments in industries such as oil & gas, power generation, chemical processing, and manufacturing automation.

Technical Specifications

| Parameter | Specification |

| Model | PFUK104 YM110002-SD |

| Function | Processor Board for ABB Advant Controller and related systems |

| Processor Type | High-speed microcontroller (ABB proprietary architecture) |

| Memory – RAM | 4 MB Dynamic RAM (volatile) |

| Memory – ROM/Flash | 2 MB Flash memory (non-volatile) |

| System Bus Support | Yes – Supports ABB Advant system bus |

| Communication Interfaces | RS-232 / RS-485 (with appropriate interface modules), MODBUS, ABB Fieldbus |

| I/O Support | Works in conjunction with separate I/O modules via backplane communication |

| Operating Voltage | 5 V DC nominal via backplane |

| Typical Power Consumption | 6.5 W |

| Dimensions | 160 × 160 × 120 mm |

| Weight | 0.8 kg |

Applications

The ABB PFUK104 YM110002-SD processor board is utilized in various industrial applications, including:

-

Process control systems

-

Manufacturing automation

-

Power generation and distribution

-

Oil and gas industry

-

Chemical processing plants

Advantages

High Reliability: Engineered for continuous operation in industrial settings.

Compact Design: Space-saving dimensions facilitate easy integration into existing systems.

Ease of Maintenance: Modular design allows for straightforward replacement and upgrades.

Global Support: Backed by ABB’s extensive global service network.

Frequently Asked Questions (FAQ)

What is the primary role of the PFUK104 YM110002-SD within an ABB control system?

This board functions as a central processor within ABB’s automation systems, handling control logic execution, real-time process coordination, and data exchange with I/O modules and system interfaces.

Which communication protocols does the PFUK104 YM110002-SD support?

It supports ABB proprietary fieldbus and system bus communication, including MODBUS and other serial communication protocols via integrated interface modules or expansion cards.

What is the typical power consumption of the processor board?

The PFUK104 typically consumes around 5–7 watts during standard operation. However, this may vary slightly depending on system load and connected peripherals.

Does the module support redundant configurations?

Yes, it can be used in a redundant CPU configuration to ensure system availability. In critical applications, a hot-standby setup allows one processor board to take over if the primary one fails.

What environmental conditions is the board rated for?

The module is designed to operate in industrial environments, with an ambient temperature range of 0°C to +60°C, relative humidity up to 95% non-condensing, and resistance to vibration/shock per IEC standards.

How is data backed up on the PFUK104 YM110002-SD?

Configuration and runtime data are stored in non-volatile memory on the board. Additionally, ABB recommends external backup using engineering software tools to save project and firmware states.

How does the PFUK104 integrate with HMI or SCADA systems?

The processor communicates with SCADA or HMI platforms via OPC servers or direct communication channels provided by ABB’s 800xA or Advant Operator interface solutions.

Is remote diagnostics or monitoring supported with this module?

Yes, the board supports remote diagnostics when connected to a networked ABB automation system. Engineers can monitor system health, logs, and alarms via ABB software from a remote engineering station.

Are there any specific installation clearances required?

Yes, to maintain airflow and avoid overheating, at least 2–3 cm clearance should be maintained on all sides when installed in a control cabinet. Avoid placing near heat sources or unshielded power lines.

What is the procedure for safely replacing this module in the field?

The board must be powered down before removal. Grounding yourself before handling the board is critical to avoid ESD damage. Insert firmly into the designated slot and secure it with retaining clips or screws before re-powering the system.

ABB PFUK104 YM110002-SD Processor Board

Manufacturer:ABB

Product Number:PFUK104 YM110002-SD

Product Type:Processor Board

Origin:Sweden

Dimensions:160 × 160 × 120 mm

Weight:0.8 kg

Views:59

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB PFUK104 YM110002-SD is a powerful and reliable processor board designed for use in ABB’s Advant Controller series and integrated process automation systems. It plays a central role in executing control algorithms, handling real-time communication, and facilitating smooth interaction between the controller and field devices in industrial applications.

As a core component of ABB’s modular automation architecture, the PFUK104 provides processing capabilities for time-critical tasks such as signal conditioning, loop control, data acquisition, and inter-module communication. It is especially suitable for complex process control environments in industries such as oil & gas, power generation, chemical processing, and manufacturing automation.

Technical Specifications

| Parameter | Specification |

| Model | PFUK104 YM110002-SD |

| Function | Processor Board for ABB Advant Controller and related systems |

| Processor Type | High-speed microcontroller (ABB proprietary architecture) |

| Memory – RAM | 4 MB Dynamic RAM (volatile) |

| Memory – ROM/Flash | 2 MB Flash memory (non-volatile) |

| System Bus Support | Yes – Supports ABB Advant system bus |

| Communication Interfaces | RS-232 / RS-485 (with appropriate interface modules), MODBUS, ABB Fieldbus |

| I/O Support | Works in conjunction with separate I/O modules via backplane communication |

| Operating Voltage | 5 V DC nominal via backplane |

| Typical Power Consumption | 6.5 W |

| Dimensions | 160 × 160 × 120 mm |

| Weight | 0.8 kg |

Applications

The ABB PFUK104 YM110002-SD processor board is utilized in various industrial applications, including:

-

Process control systems

-

Manufacturing automation

-

Power generation and distribution

-

Oil and gas industry

-

Chemical processing plants

Advantages

High Reliability: Engineered for continuous operation in industrial settings.

Compact Design: Space-saving dimensions facilitate easy integration into existing systems.

Ease of Maintenance: Modular design allows for straightforward replacement and upgrades.

Global Support: Backed by ABB’s extensive global service network.

Frequently Asked Questions (FAQ)

What is the primary role of the PFUK104 YM110002-SD within an ABB control system?

This board functions as a central processor within ABB’s automation systems, handling control logic execution, real-time process coordination, and data exchange with I/O modules and system interfaces.

Which communication protocols does the PFUK104 YM110002-SD support?

It supports ABB proprietary fieldbus and system bus communication, including MODBUS and other serial communication protocols via integrated interface modules or expansion cards.

What is the typical power consumption of the processor board?

The PFUK104 typically consumes around 5–7 watts during standard operation. However, this may vary slightly depending on system load and connected peripherals.

Does the module support redundant configurations?

Yes, it can be used in a redundant CPU configuration to ensure system availability. In critical applications, a hot-standby setup allows one processor board to take over if the primary one fails.

What environmental conditions is the board rated for?

The module is designed to operate in industrial environments, with an ambient temperature range of 0°C to +60°C, relative humidity up to 95% non-condensing, and resistance to vibration/shock per IEC standards.

How is data backed up on the PFUK104 YM110002-SD?

Configuration and runtime data are stored in non-volatile memory on the board. Additionally, ABB recommends external backup using engineering software tools to save project and firmware states.

How does the PFUK104 integrate with HMI or SCADA systems?

The processor communicates with SCADA or HMI platforms via OPC servers or direct communication channels provided by ABB’s 800xA or Advant Operator interface solutions.

Is remote diagnostics or monitoring supported with this module?

Yes, the board supports remote diagnostics when connected to a networked ABB automation system. Engineers can monitor system health, logs, and alarms via ABB software from a remote engineering station.

Are there any specific installation clearances required?

Yes, to maintain airflow and avoid overheating, at least 2–3 cm clearance should be maintained on all sides when installed in a control cabinet. Avoid placing near heat sources or unshielded power lines.

What is the procedure for safely replacing this module in the field?

The board must be powered down before removal. Grounding yourself before handling the board is critical to avoid ESD damage. Insert firmly into the designated slot and secure it with retaining clips or screws before re-powering the system.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...