Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

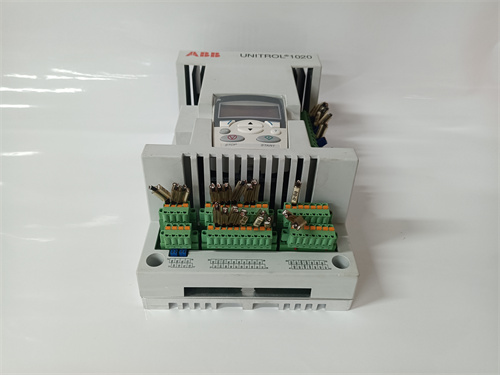

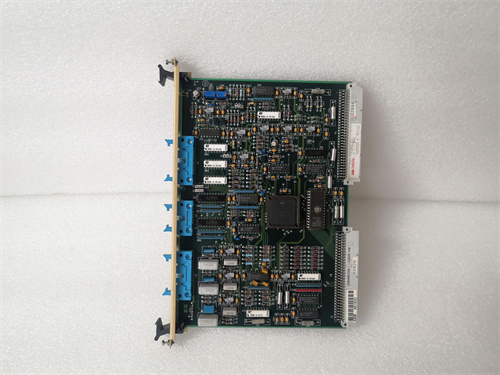

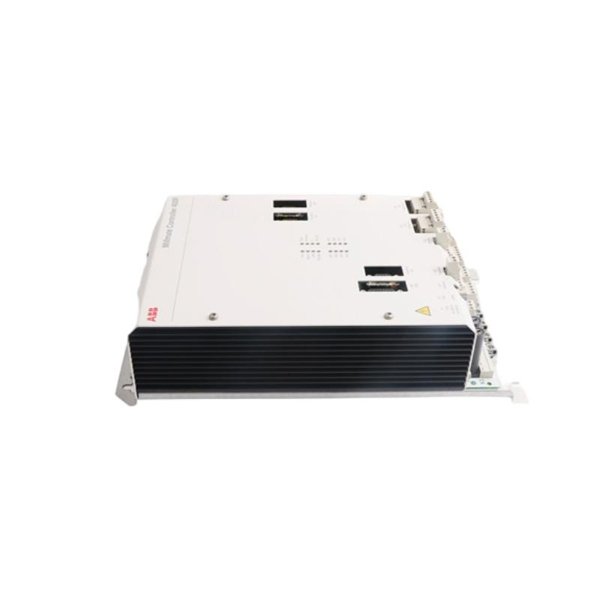

ABB PXAA 401 3BSE017233R1 Central Processing Unit

Manufacturer:ABB

Product Number:PXAA 401 3BSE017233R1

Product Type:Central Processing Unit

Origin:Switzerland

Dimensions:380 x 235 x 110mm

Weight:5 kg

Views:33

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB PXAA 401 3BSE017233R1 is a high-performance central processing unit (CPU) module used in ABB’s industrial automation systems, particularly within the Symphony Plus platform. As a critical core component of a distributed control system (DCS), the PXAA 401 is designed to execute advanced control logic, manage communications with field devices, and interface with operator workstations, making it indispensable in demanding process automation environments.

With its integrated real-time operating system, robust I/O handling capabilities, and powerful internal processor, the PXAA 401 ensures stable and deterministic execution of control tasks. The module is equipped with redundant communication support, multiple I/O slots, and versatile mounting options, making it ideal for mission-critical applications that require high reliability, long service life, and scalability.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Name | PXAA 401 |

| Order Code | 3BSE017233R1 |

| Brand | ABB |

| Product Type | Central Processing Unit (CPU) |

| System Platform | Symphony Plus |

| Processor | High-speed industrial-grade processor |

| Memory | Integrated RAM and Flash memory |

| I/O Capacity | Supports multiple digital and analog I/O modules |

| Communication Ports | Ethernet, Serial, USB, PROFIBUS (via add-ons) |

| Redundancy | Supported (CPU and communication redundancy) |

| Operating System | ABB RTOS (Real-Time Operating System) |

| Mounting | Rack-mounted |

| Power Supply | 24 V DC (from backplane) |

| Protection Class | IP20 (installed in enclosure) |

| Operating Temperature | 0°C to +55°C |

| Dimensions | 380 × 235 × 110 mm |

| Weight | 5 kg |

Applications

Oil and Gas Refining

The PXAA 401 is widely deployed in refinery control rooms and process skids for managing complex automation tasks including distillation, blending, and compressor control.

Power Generation Plants

Acts as the main control CPU in gas turbines, hydroelectric plants, and combined cycle power systems. It integrates seamlessly with IEDs and SCADA interfaces.

Chemical and Petrochemical Processing

Manages large-scale, batch-based or continuous production processes where timing, redundancy, and control precision are vital.

Water and Wastewater Management

Used to handle filtration, chemical dosing, pump sequencing, and treatment plant automation across distributed sites.

Metallurgical and Cement Industries

Ensures real-time process control in blast furnaces, kilns, grinding mills, and material handling lines.

Pharmaceutical Manufacturing

Supports GMP-compliant, validated process environments requiring repeatable automation and secure data logging.

Advantages

High-Performance Processing

Built-in industrial CPU optimized for real-time process control with minimal latency.

System Redundancy

Native support for hot standby and communication redundancy increases system reliability and uptime.

Integrated I/O Expansion

Scalable architecture with support for a wide variety of I/O modules and networks, including PROFIBUS and Modbus.

Long Lifecycle and Reliability

Designed for extended operation in harsh industrial environments with guaranteed product availability and lifecycle support from ABB.

Versatile Connectivity

Multiple ports and protocols enable easy integration with field devices, HMI systems, and third-party platforms.

Secure Architecture

Built-in protections, watchdog timers, and error checking enhance control integrity and minimize downtime.

Frequently Asked Questions (FAQ)

Q1: What is the primary role of PXAA 401 in the control system?

A1: It functions as the central processor that executes control logic, communicates with I/O modules, and connects to higher-level SCADA systems.

Q2: Can it be used in redundant CPU configurations?

A2: Yes, PXAA 401 supports redundant configurations for fault-tolerant operation.

Q3: What communication protocols are supported?

A3: Standard support includes Ethernet and serial communication; additional protocols like PROFIBUS and Modbus are supported via expansion.

Q4: Is the PXAA 401 compatible with legacy ABB systems?

A4: Yes, it is designed for integration within the Symphony Plus environment, including backward compatibility.

Q5: How is the unit powered?

A5: It is powered via the backplane using a 24 V DC supply, eliminating the need for a dedicated power source.

Q6: Is the module programmable via standard tools?

A6: Yes, it is configured and programmed using ABB Control Builder or similar engineering tools.

Q7: Can it be mounted vertically or only horizontally?

A7: Typically mounted in standard 19-inch control racks; orientation should follow ABB’s environmental guidelines.

Q8: How is firmware upgraded?

A8: Firmware upgrades are performed through engineering tools during scheduled maintenance periods.

Q9: Is the PXAA 401 suitable for safety-critical applications?

A9: Yes, especially when used in redundant or SIL-rated systems following ABB guidelines.

Q10: What kind of support does ABB provide for this module?

A10: ABB offers full lifecycle support, including spare parts, service contracts, and firmware updates.

ABB PXAA 401 3BSE017233R1 Central Processing Unit

Manufacturer:ABB

Product Number:PXAA 401 3BSE017233R1

Product Type:Central Processing Unit

Origin:Switzerland

Dimensions:380 x 235 x 110mm

Weight:5 kg

Views:33

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB PXAA 401 3BSE017233R1 is a high-performance central processing unit (CPU) module used in ABB’s industrial automation systems, particularly within the Symphony Plus platform. As a critical core component of a distributed control system (DCS), the PXAA 401 is designed to execute advanced control logic, manage communications with field devices, and interface with operator workstations, making it indispensable in demanding process automation environments.

With its integrated real-time operating system, robust I/O handling capabilities, and powerful internal processor, the PXAA 401 ensures stable and deterministic execution of control tasks. The module is equipped with redundant communication support, multiple I/O slots, and versatile mounting options, making it ideal for mission-critical applications that require high reliability, long service life, and scalability.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Name | PXAA 401 |

| Order Code | 3BSE017233R1 |

| Brand | ABB |

| Product Type | Central Processing Unit (CPU) |

| System Platform | Symphony Plus |

| Processor | High-speed industrial-grade processor |

| Memory | Integrated RAM and Flash memory |

| I/O Capacity | Supports multiple digital and analog I/O modules |

| Communication Ports | Ethernet, Serial, USB, PROFIBUS (via add-ons) |

| Redundancy | Supported (CPU and communication redundancy) |

| Operating System | ABB RTOS (Real-Time Operating System) |

| Mounting | Rack-mounted |

| Power Supply | 24 V DC (from backplane) |

| Protection Class | IP20 (installed in enclosure) |

| Operating Temperature | 0°C to +55°C |

| Dimensions | 380 × 235 × 110 mm |

| Weight | 5 kg |

Applications

Oil and Gas Refining

The PXAA 401 is widely deployed in refinery control rooms and process skids for managing complex automation tasks including distillation, blending, and compressor control.

Power Generation Plants

Acts as the main control CPU in gas turbines, hydroelectric plants, and combined cycle power systems. It integrates seamlessly with IEDs and SCADA interfaces.

Chemical and Petrochemical Processing

Manages large-scale, batch-based or continuous production processes where timing, redundancy, and control precision are vital.

Water and Wastewater Management

Used to handle filtration, chemical dosing, pump sequencing, and treatment plant automation across distributed sites.

Metallurgical and Cement Industries

Ensures real-time process control in blast furnaces, kilns, grinding mills, and material handling lines.

Pharmaceutical Manufacturing

Supports GMP-compliant, validated process environments requiring repeatable automation and secure data logging.

Advantages

High-Performance Processing

Built-in industrial CPU optimized for real-time process control with minimal latency.

System Redundancy

Native support for hot standby and communication redundancy increases system reliability and uptime.

Integrated I/O Expansion

Scalable architecture with support for a wide variety of I/O modules and networks, including PROFIBUS and Modbus.

Long Lifecycle and Reliability

Designed for extended operation in harsh industrial environments with guaranteed product availability and lifecycle support from ABB.

Versatile Connectivity

Multiple ports and protocols enable easy integration with field devices, HMI systems, and third-party platforms.

Secure Architecture

Built-in protections, watchdog timers, and error checking enhance control integrity and minimize downtime.

Frequently Asked Questions (FAQ)

Q1: What is the primary role of PXAA 401 in the control system?

A1: It functions as the central processor that executes control logic, communicates with I/O modules, and connects to higher-level SCADA systems.

Q2: Can it be used in redundant CPU configurations?

A2: Yes, PXAA 401 supports redundant configurations for fault-tolerant operation.

Q3: What communication protocols are supported?

A3: Standard support includes Ethernet and serial communication; additional protocols like PROFIBUS and Modbus are supported via expansion.

Q4: Is the PXAA 401 compatible with legacy ABB systems?

A4: Yes, it is designed for integration within the Symphony Plus environment, including backward compatibility.

Q5: How is the unit powered?

A5: It is powered via the backplane using a 24 V DC supply, eliminating the need for a dedicated power source.

Q6: Is the module programmable via standard tools?

A6: Yes, it is configured and programmed using ABB Control Builder or similar engineering tools.

Q7: Can it be mounted vertically or only horizontally?

A7: Typically mounted in standard 19-inch control racks; orientation should follow ABB’s environmental guidelines.

Q8: How is firmware upgraded?

A8: Firmware upgrades are performed through engineering tools during scheduled maintenance periods.

Q9: Is the PXAA 401 suitable for safety-critical applications?

A9: Yes, especially when used in redundant or SIL-rated systems following ABB guidelines.

Q10: What kind of support does ABB provide for this module?

A10: ABB offers full lifecycle support, including spare parts, service contracts, and firmware updates.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...