Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

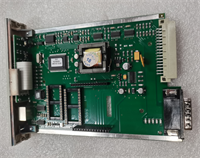

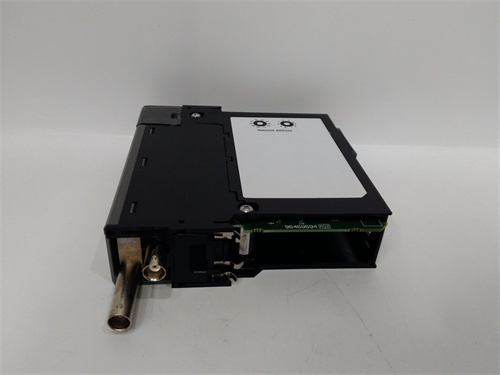

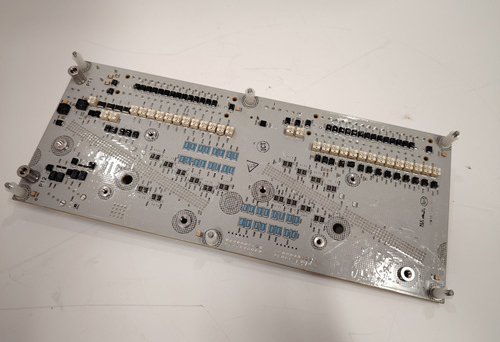

Honeywell 620-1690 Processor Rack

Manufacturer:Honeywell

Product Number:620-1690

Product Type:Processor Rack

Origin:USA

Dimensions:482 x 177 x 250 mm

Weight:6.26 kg

Views:45

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

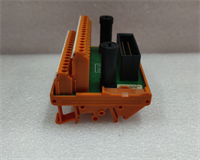

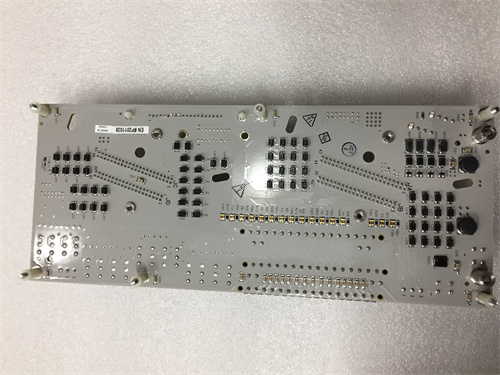

The Honeywell 620-1690 Processor Rack is a critical component in the TDC 3000 and TPS (TotalPlant Solution) distributed control systems (DCS) developed by Honeywell. This unit serves as the central hub for housing processor modules, ensuring reliable communication between control and monitoring components across various industrial automation environments. Designed for high availability and fault tolerance, the 620-1690 rack supports real-time process control, diagnostics, and seamless integration with Honeywell’s sophisticated automation infrastructure.

Manufactured with robust industrial standards, the 620-1690 is ideal for process-intensive sectors such as petrochemicals, power generation, refining, and water treatment plants. The rack is built for ease of installation, maintenance, and expansion, ensuring longevity and scalability in mission-critical applications.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | Honeywell 620-1690 |

| Product Type | Processor Rack / Module Rack |

| System Compatibility | TDC 3000, TPS Systems |

| Slots Available | Typically supports multiple I/O or processor modules |

| Communication Bus | High-speed backplane interface |

| Mounting Type | Standard industrial rack-mount |

| Material | Industrial-grade steel |

| Power Supply Support | Supports redundant power supplies |

| Cooling System | Passive or forced-air (dependent on enclosure) |

| Operating Temperature | 0°C to 60°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5%–95% (non-condensing) |

| Certifications | CE, UL, CSA, ATEX (depending on the application) |

| Dimensions (W x H x D) | 482 x 177 x 250 mm |

| Weight | 6.26 kg |

Applications

The Honeywell 620-1690 Processor Rack is engineered for a wide variety of industrial applications where precision, safety, and system availability are paramount. Typical use cases include:

Oil & Gas Refineries – Centralized process control for distillation, cracking, and blending.

Power Plants – Turbine and generator monitoring with redundancy and fast response.

Chemical Manufacturing – Real-time control of reactors and material handling.

Water & Wastewater Treatment – Supervisory control and data acquisition (SCADA) backbone.

Pharmaceutical Processing – GMP-compliant process automation.

Paper & Pulp Industries – Process synchronization and automation of mills.

Product Advantages

Modular Design: Supports scalable system expansion without disrupting operations.

Robust Construction: Industrial-grade housing ensures reliability in harsh environments.

Seamless Integration: Fully compatible with Honeywell TDC 3000 and TPS systems.

Redundancy Options: Built-in support for redundant configurations to enhance system availability.

Ease of Maintenance: Hot-swappable modules minimize downtime during servicing.

High-Speed Backplane: Ensures low-latency communication between modules.

Longevity: Proven reliability in long-term industrial deployments.

Vendor Support: Backed by Honeywell’s global support network and spare parts availability.

Enhanced Diagnostics: Supports system-level health monitoring and alerts.

Certified Compliance: Complies with international industrial automation standards.

Frequently Asked Questions (FAQ)

What is the primary function of the Honeywell 620-1690 Processor Rack?

The 620-1690 serves as the central rack in a Honeywell distributed control system, designed to host processor and I/O modules that manage process automation tasks.

How is the 620-1690 installed in a typical industrial setup?

It is mounted in a standard 19-inch equipment rack or cabinet and connected to the power supply and communication bus of the DCS system.

Can this processor rack be used in hazardous environments?

While the unit itself is industrial-grade, its use in hazardous areas depends on enclosure ratings and compliance with explosion-proof or intrinsically safe standards.

What kind of communication interface does the rack use?

The rack includes a high-speed backplane that supports internal communication between modules and external interfaces for integration with plant-wide systems.

Does the rack provide support for system diagnostics?

Yes, it is designed to work with Honeywell control systems that offer real-time diagnostics and status indicators to help operators monitor performance.

Is this product suitable for systems requiring high availability?

Absolutely. The 620-1690 supports configurations with redundant processors and power supplies, which are crucial in high-availability environments.

What modules are compatible with the 620-1690 rack?

The rack supports various Honeywell modules such as CPU processors, I/O cards, communication interfaces, and power modules designed for the 620 series.

Can the modules inside the rack be replaced without shutting down the entire system?

Yes, most modules are hot-swappable, allowing for replacement or upgrade during live operation, minimizing downtime.

How long does it take to install and configure the rack in an existing system?

Installation typically takes a few hours, depending on the site conditions, with configuration handled via Honeywell’s system software tools.

What maintenance is required to keep the rack operating reliably?

Periodic inspections, dust cleaning, and connector checks are recommended. Honeywell also suggests routine firmware updates and module testing as part of standard maintenance procedures.

Honeywell 620-1690 Processor Rack

Manufacturer:Honeywell

Product Number:620-1690

Product Type:Processor Rack

Origin:USA

Dimensions:482 x 177 x 250 mm

Weight:6.26 kg

Views:45

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell 620-1690 Processor Rack is a critical component in the TDC 3000 and TPS (TotalPlant Solution) distributed control systems (DCS) developed by Honeywell. This unit serves as the central hub for housing processor modules, ensuring reliable communication between control and monitoring components across various industrial automation environments. Designed for high availability and fault tolerance, the 620-1690 rack supports real-time process control, diagnostics, and seamless integration with Honeywell’s sophisticated automation infrastructure.

Manufactured with robust industrial standards, the 620-1690 is ideal for process-intensive sectors such as petrochemicals, power generation, refining, and water treatment plants. The rack is built for ease of installation, maintenance, and expansion, ensuring longevity and scalability in mission-critical applications.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | Honeywell 620-1690 |

| Product Type | Processor Rack / Module Rack |

| System Compatibility | TDC 3000, TPS Systems |

| Slots Available | Typically supports multiple I/O or processor modules |

| Communication Bus | High-speed backplane interface |

| Mounting Type | Standard industrial rack-mount |

| Material | Industrial-grade steel |

| Power Supply Support | Supports redundant power supplies |

| Cooling System | Passive or forced-air (dependent on enclosure) |

| Operating Temperature | 0°C to 60°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5%–95% (non-condensing) |

| Certifications | CE, UL, CSA, ATEX (depending on the application) |

| Dimensions (W x H x D) | 482 x 177 x 250 mm |

| Weight | 6.26 kg |

Applications

The Honeywell 620-1690 Processor Rack is engineered for a wide variety of industrial applications where precision, safety, and system availability are paramount. Typical use cases include:

Oil & Gas Refineries – Centralized process control for distillation, cracking, and blending.

Power Plants – Turbine and generator monitoring with redundancy and fast response.

Chemical Manufacturing – Real-time control of reactors and material handling.

Water & Wastewater Treatment – Supervisory control and data acquisition (SCADA) backbone.

Pharmaceutical Processing – GMP-compliant process automation.

Paper & Pulp Industries – Process synchronization and automation of mills.

Product Advantages

Modular Design: Supports scalable system expansion without disrupting operations.

Robust Construction: Industrial-grade housing ensures reliability in harsh environments.

Seamless Integration: Fully compatible with Honeywell TDC 3000 and TPS systems.

Redundancy Options: Built-in support for redundant configurations to enhance system availability.

Ease of Maintenance: Hot-swappable modules minimize downtime during servicing.

High-Speed Backplane: Ensures low-latency communication between modules.

Longevity: Proven reliability in long-term industrial deployments.

Vendor Support: Backed by Honeywell’s global support network and spare parts availability.

Enhanced Diagnostics: Supports system-level health monitoring and alerts.

Certified Compliance: Complies with international industrial automation standards.

Frequently Asked Questions (FAQ)

What is the primary function of the Honeywell 620-1690 Processor Rack?

The 620-1690 serves as the central rack in a Honeywell distributed control system, designed to host processor and I/O modules that manage process automation tasks.

How is the 620-1690 installed in a typical industrial setup?

It is mounted in a standard 19-inch equipment rack or cabinet and connected to the power supply and communication bus of the DCS system.

Can this processor rack be used in hazardous environments?

While the unit itself is industrial-grade, its use in hazardous areas depends on enclosure ratings and compliance with explosion-proof or intrinsically safe standards.

What kind of communication interface does the rack use?

The rack includes a high-speed backplane that supports internal communication between modules and external interfaces for integration with plant-wide systems.

Does the rack provide support for system diagnostics?

Yes, it is designed to work with Honeywell control systems that offer real-time diagnostics and status indicators to help operators monitor performance.

Is this product suitable for systems requiring high availability?

Absolutely. The 620-1690 supports configurations with redundant processors and power supplies, which are crucial in high-availability environments.

What modules are compatible with the 620-1690 rack?

The rack supports various Honeywell modules such as CPU processors, I/O cards, communication interfaces, and power modules designed for the 620 series.

Can the modules inside the rack be replaced without shutting down the entire system?

Yes, most modules are hot-swappable, allowing for replacement or upgrade during live operation, minimizing downtime.

How long does it take to install and configure the rack in an existing system?

Installation typically takes a few hours, depending on the site conditions, with configuration handled via Honeywell’s system software tools.

What maintenance is required to keep the rack operating reliably?

Periodic inspections, dust cleaning, and connector checks are recommended. Honeywell also suggests routine firmware updates and module testing as part of standard maintenance procedures.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...