Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

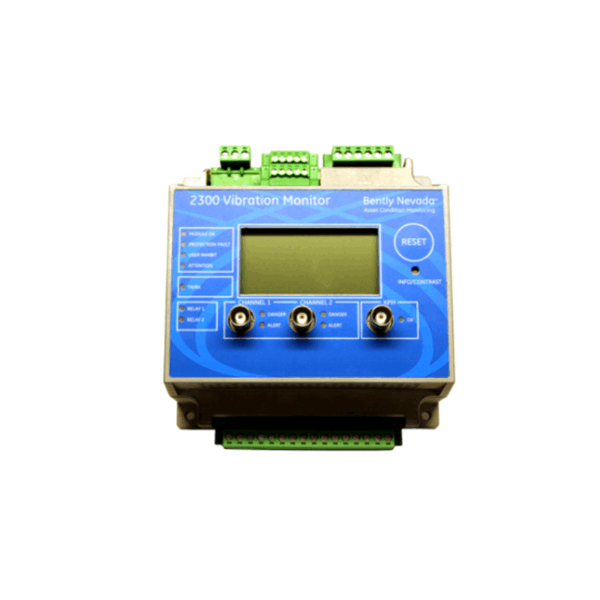

Bently Nevada 2300/20-CN Vibration Monitor

Manufacturer:Bently Nevada

Product Number:2300/20-CN

Product Type:Vibration Monitor

Origin:USA

Dimensions:127 x 127 x 76.2 mm

Weight:1.03 kg

Views:89

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 2300/20-CN Vibration Monitor is a state-of-the-art device engineered for continuous monitoring and protection of rotating machinery. It offers early detection of mechanical issues, thereby preventing costly downtime and extending equipment lifespan. Designed for seamless integration into existing systems, this monitor is ideal for industries such as oil and gas, power generation, water treatment, pulp and paper, manufacturing, mining, and cement.

Key Features

Dual Vibration Channels: Accommodates seismic or proximity measurement inputs from various accelerometers, Velomitor, and Proximitor types.

Speed Input Channel: Facilitates time-synchronous measurements, enhancing diagnostic capabilities.

Configurable Outputs: Includes two 4-20 mA outputs with an internal current loop power supply, allowing for flexible interfacing with Distributed Control Systems (DCS).

Communication Interfaces: Supports Modbus over Ethernet, enabling efficient data transmission and system integration.

Alarm Functionality: Provides high vibration level alarming with relay contact outputs for immediate response to abnormal conditions.

Technical Specifications

| Parameter | Specification |

|---|---|

| Input Channels | Two vibration channels (seismic/proximity), one speed channel |

| Supported Sensors | Accelerometers, Velomitor, Proximitor types |

| Outputs | Two 4-20 mA outputs, relay contacts |

| Communication Protocols | Modbus over Ethernet |

| Buffered Outputs | Three buffered transducer outputs via BNC connectors |

| Operating Voltage | 18–36 VDC, 6.5 W power consumption |

| Operating Temperature | -30°C to +65°C (-22°F to +149°F) |

| Storage Temperature | -40°C to +85°C (-40°F to +185°F) |

| Humidity | Up to 95%, non-condensing |

| Dimensions (H x W x D) | 127 x 127 x 76.2 mm |

| Weight | 1.03 kg |

Applications

Rotating Equipment: Continuous monitoring of pumps, motors, compressors, and turbines to detect imbalance, misalignment, and bearing faults.

Industrial Processes: Ensuring operational efficiency and safety in industries like oil and gas, power generation, and manufacturing.

Predictive Maintenance: Facilitating condition-based maintenance strategies by providing real-time data on machinery health.

Advantages

Early Fault Detection: Identifies potential issues before they escalate, reducing unplanned downtime and maintenance costs.

Versatile Sensor Compatibility: Supports a range of sensor types, offering flexibility in monitoring various machinery configurations.

Robust Communication: Modbus over Ethernet ensures reliable data transmission and easy integration with existing control systems.

User-Friendly Interface: Configurable outputs and intuitive alarm settings simplify operation and enhance responsiveness.

Frequently Asked Questions (FAQ)

What types of machinery can the 2300/20-CN monitor?

It is designed for rotating equipment such as pumps, motors, compressors, and turbines.

What sensor types are compatible with this monitor?

It supports accelerometers, Velomitor, and Proximitor sensors.

How does the monitor communicate with other systems?

It uses Modbus over Ethernet for seamless integration.

What are the output options available?

It provides two 4-20 mA outputs and relay contact outputs.

Is the monitor suitable for harsh environments?

Yes, it operates within -30°C to +65°C and up to 95% non-condensing humidity.

Can it be integrated into existing Distributed Control Systems (DCS)?

Yes, its configurable outputs allow easy interfacing with DCS.

What kind of power supply does it require?

It operates on 18–36 VDC with a power consumption of 6.5 W.

Does it provide real-time data?

Yes, it offers continuous monitoring and real-time data on machinery health.

What alarm functionalities are included?

It features high vibration level alarming with relay contact outputs.

How is the monitor mounted?

It is designed for panel mounting in industrial settings.

Bently Nevada 2300/20-CN Vibration Monitor

Manufacturer:Bently Nevada

Product Number:2300/20-CN

Product Type:Vibration Monitor

Origin:USA

Dimensions:127 x 127 x 76.2 mm

Weight:1.03 kg

Views:89

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 2300/20-CN Vibration Monitor is a state-of-the-art device engineered for continuous monitoring and protection of rotating machinery. It offers early detection of mechanical issues, thereby preventing costly downtime and extending equipment lifespan. Designed for seamless integration into existing systems, this monitor is ideal for industries such as oil and gas, power generation, water treatment, pulp and paper, manufacturing, mining, and cement.

Key Features

Dual Vibration Channels: Accommodates seismic or proximity measurement inputs from various accelerometers, Velomitor, and Proximitor types.

Speed Input Channel: Facilitates time-synchronous measurements, enhancing diagnostic capabilities.

Configurable Outputs: Includes two 4-20 mA outputs with an internal current loop power supply, allowing for flexible interfacing with Distributed Control Systems (DCS).

Communication Interfaces: Supports Modbus over Ethernet, enabling efficient data transmission and system integration.

Alarm Functionality: Provides high vibration level alarming with relay contact outputs for immediate response to abnormal conditions.

Technical Specifications

| Parameter | Specification |

|---|---|

| Input Channels | Two vibration channels (seismic/proximity), one speed channel |

| Supported Sensors | Accelerometers, Velomitor, Proximitor types |

| Outputs | Two 4-20 mA outputs, relay contacts |

| Communication Protocols | Modbus over Ethernet |

| Buffered Outputs | Three buffered transducer outputs via BNC connectors |

| Operating Voltage | 18–36 VDC, 6.5 W power consumption |

| Operating Temperature | -30°C to +65°C (-22°F to +149°F) |

| Storage Temperature | -40°C to +85°C (-40°F to +185°F) |

| Humidity | Up to 95%, non-condensing |

| Dimensions (H x W x D) | 127 x 127 x 76.2 mm |

| Weight | 1.03 kg |

Applications

Rotating Equipment: Continuous monitoring of pumps, motors, compressors, and turbines to detect imbalance, misalignment, and bearing faults.

Industrial Processes: Ensuring operational efficiency and safety in industries like oil and gas, power generation, and manufacturing.

Predictive Maintenance: Facilitating condition-based maintenance strategies by providing real-time data on machinery health.

Advantages

Early Fault Detection: Identifies potential issues before they escalate, reducing unplanned downtime and maintenance costs.

Versatile Sensor Compatibility: Supports a range of sensor types, offering flexibility in monitoring various machinery configurations.

Robust Communication: Modbus over Ethernet ensures reliable data transmission and easy integration with existing control systems.

User-Friendly Interface: Configurable outputs and intuitive alarm settings simplify operation and enhance responsiveness.

Frequently Asked Questions (FAQ)

What types of machinery can the 2300/20-CN monitor?

It is designed for rotating equipment such as pumps, motors, compressors, and turbines.

What sensor types are compatible with this monitor?

It supports accelerometers, Velomitor, and Proximitor sensors.

How does the monitor communicate with other systems?

It uses Modbus over Ethernet for seamless integration.

What are the output options available?

It provides two 4-20 mA outputs and relay contact outputs.

Is the monitor suitable for harsh environments?

Yes, it operates within -30°C to +65°C and up to 95% non-condensing humidity.

Can it be integrated into existing Distributed Control Systems (DCS)?

Yes, its configurable outputs allow easy interfacing with DCS.

What kind of power supply does it require?

It operates on 18–36 VDC with a power consumption of 6.5 W.

Does it provide real-time data?

Yes, it offers continuous monitoring and real-time data on machinery health.

What alarm functionalities are included?

It features high vibration level alarming with relay contact outputs.

How is the monitor mounted?

It is designed for panel mounting in industrial settings.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...