Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

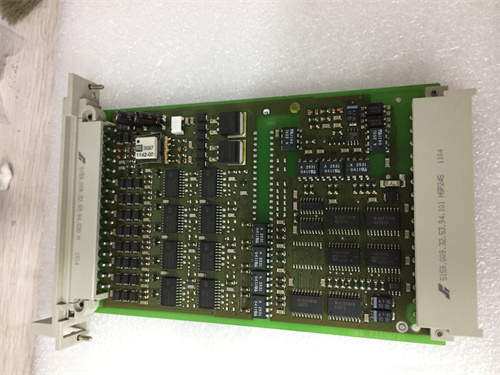

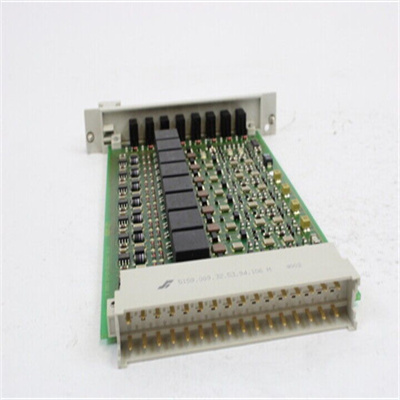

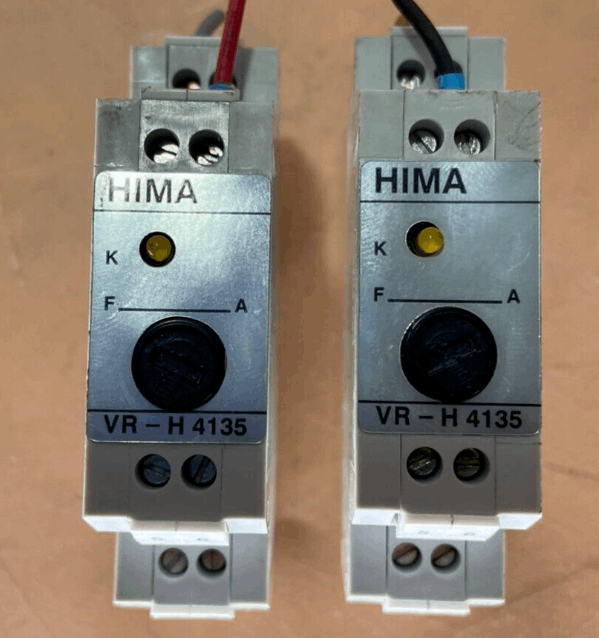

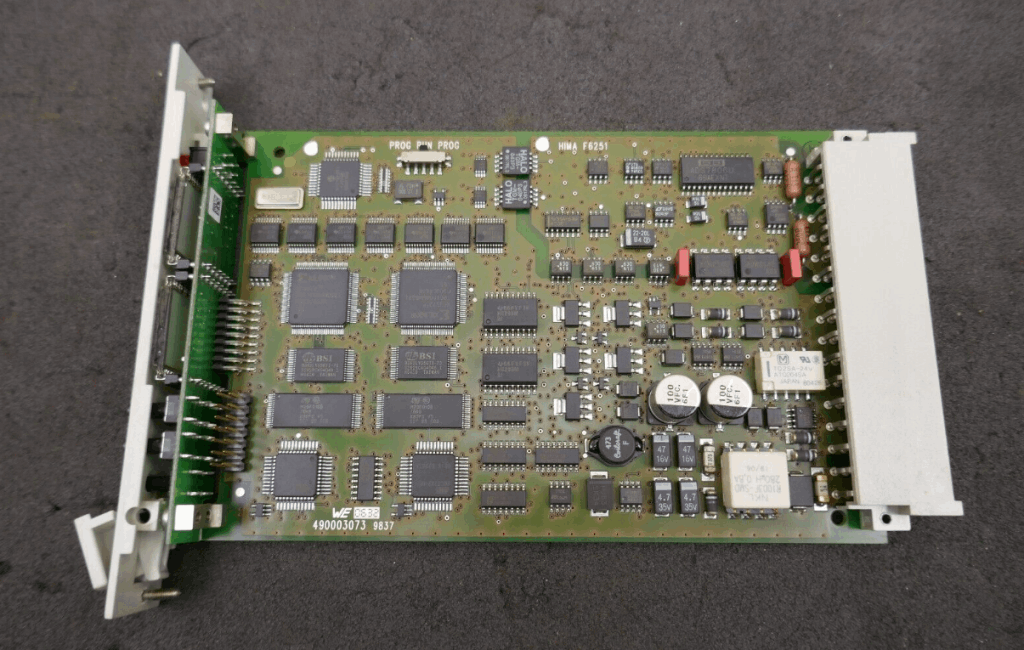

Hima F8560X Central Processor Module

Manufacturer:HIMA

Product Number:F8560X

Product Type:Central Processor Module

Origin:Germany

Dimensions:260 x 110 x 25 mm

Weight :0.85 kg

Views:176

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

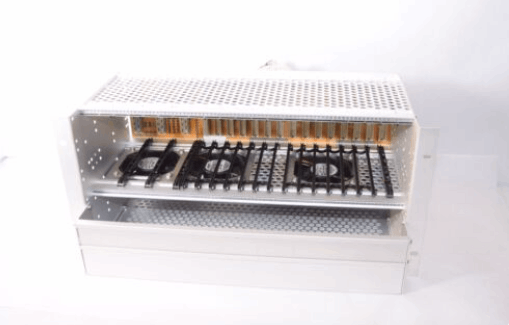

The HIMA F8560X Central Processor Module is a high-performance CPU module designed for use in HIMA HIMax and HIQuad safety systems. As the core processing unit, it ensures the execution of safety-critical applications with deterministic performance and compliance with international safety standards such as IEC 61508 and SIL 3.

Technical Specifications

| Parameter | Description |

|---|---|

| Product Model | HIMA F8560X Central Processor Module |

| Dimensions | 260 x 110 x 25 mm |

| Weight | 0.85 kg |

| Power Supply Voltage | 24 V DC (redundant power supply supported) |

| Power Consumption | ~ 15 W |

| Processor Type | High-performance CPU with hardware redundancy capability |

| Communication Interfaces | Ethernet, serial communication, system bus interface |

| Memory Capacity | Large onboard memory with support for safety application storage and logs |

| Operating Temperature | 0 °C to +60 °C |

| Storage Temperature | -25 °C to +70 °C |

| Certifications | IEC 61508, SIL 3, ATEX, CE, TÜV |

| Installation | Rack-mounted within HIMA HIMax / HIQuad chassis |

Product Applications

Oil & Gas: Emergency shutdown (ESD), fire and gas detection, and burner management systems.

Chemical Industry: Reactor safety, process safeguarding, and plant-wide safety controls.

Power Generation: Turbine protection, boiler safety, and distributed safety monitoring.

Rail & Transport: Fail-safe control systems for railway signaling and safety monitoring.

Industrial Automation: Integration in complex safety architectures requiring SIL 3 compliance.

Product Advantages

High Reliability: Built with redundancy and fault-tolerant architecture to minimize downtime.

SIL 3 Certified: Fully compliant with IEC 61508 standards for functional safety applications.

Scalable Architecture: Suitable for small systems as well as large distributed safety platforms.

Fast Processing: High CPU performance ensures real-time execution of critical safety tasks.

Secure Communication: Multiple industrial communication interfaces with cybersecurity compliance.

Seamless Integration: Compatible with other HIMA modules and scalable within HIMax and HIQuad systems.

FAQ

Q1: What safety standard does the HIMA F8560X comply with?

A1: It complies with IEC 61508 and is certified up to SIL 3.

Q2: Can the F8560X be used in redundant configurations?

A2: Yes, it supports hot-redundant configurations for fault tolerance and high availability.

Q3: Which HIMA systems is the F8560X compatible with?

A3: It is designed for HIMax and HIQuad safety systems.

Q4: What type of communication interfaces are available?

A4: The module supports Ethernet, serial interfaces, and the HIMA system bus.

Q5: Does the module support event and data logging?

A5: Yes, it has onboard memory for application programs, event logging, and diagnostic data.

Q6: Can the F8560X operate under harsh environmental conditions?

A6: Yes, it is designed for industrial environments with an operating temperature range of 0 °C to +60 °C.

Q7: Is the F8560X certified for use in hazardous areas?

A7: Yes, it holds ATEX and TÜV certifications for use in safety-critical environments.

Q8: How is the power supplied to the module?

A8: It operates with a 24 V DC power supply and supports redundant power connections.

Q9: What happens if the primary processor fails?

A9: In redundant configurations, the secondary processor takes over instantly without process interruption.

Q10: Can the F8560X be integrated with third-party control systems?

A10: Yes, it can be integrated through standard industrial communication protocols.

Hima F8560X Central Processor Module

Manufacturer:HIMA

Product Number:F8560X

Product Type:Central Processor Module

Origin:Germany

Dimensions:260 x 110 x 25 mm

Weight :0.85 kg

Views:176

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The HIMA F8560X Central Processor Module is a high-performance CPU module designed for use in HIMA HIMax and HIQuad safety systems. As the core processing unit, it ensures the execution of safety-critical applications with deterministic performance and compliance with international safety standards such as IEC 61508 and SIL 3.

Technical Specifications

| Parameter | Description |

|---|---|

| Product Model | HIMA F8560X Central Processor Module |

| Dimensions | 260 x 110 x 25 mm |

| Weight | 0.85 kg |

| Power Supply Voltage | 24 V DC (redundant power supply supported) |

| Power Consumption | ~ 15 W |

| Processor Type | High-performance CPU with hardware redundancy capability |

| Communication Interfaces | Ethernet, serial communication, system bus interface |

| Memory Capacity | Large onboard memory with support for safety application storage and logs |

| Operating Temperature | 0 °C to +60 °C |

| Storage Temperature | -25 °C to +70 °C |

| Certifications | IEC 61508, SIL 3, ATEX, CE, TÜV |

| Installation | Rack-mounted within HIMA HIMax / HIQuad chassis |

Product Applications

Oil & Gas: Emergency shutdown (ESD), fire and gas detection, and burner management systems.

Chemical Industry: Reactor safety, process safeguarding, and plant-wide safety controls.

Power Generation: Turbine protection, boiler safety, and distributed safety monitoring.

Rail & Transport: Fail-safe control systems for railway signaling and safety monitoring.

Industrial Automation: Integration in complex safety architectures requiring SIL 3 compliance.

Product Advantages

High Reliability: Built with redundancy and fault-tolerant architecture to minimize downtime.

SIL 3 Certified: Fully compliant with IEC 61508 standards for functional safety applications.

Scalable Architecture: Suitable for small systems as well as large distributed safety platforms.

Fast Processing: High CPU performance ensures real-time execution of critical safety tasks.

Secure Communication: Multiple industrial communication interfaces with cybersecurity compliance.

Seamless Integration: Compatible with other HIMA modules and scalable within HIMax and HIQuad systems.

FAQ

Q1: What safety standard does the HIMA F8560X comply with?

A1: It complies with IEC 61508 and is certified up to SIL 3.

Q2: Can the F8560X be used in redundant configurations?

A2: Yes, it supports hot-redundant configurations for fault tolerance and high availability.

Q3: Which HIMA systems is the F8560X compatible with?

A3: It is designed for HIMax and HIQuad safety systems.

Q4: What type of communication interfaces are available?

A4: The module supports Ethernet, serial interfaces, and the HIMA system bus.

Q5: Does the module support event and data logging?

A5: Yes, it has onboard memory for application programs, event logging, and diagnostic data.

Q6: Can the F8560X operate under harsh environmental conditions?

A6: Yes, it is designed for industrial environments with an operating temperature range of 0 °C to +60 °C.

Q7: Is the F8560X certified for use in hazardous areas?

A7: Yes, it holds ATEX and TÜV certifications for use in safety-critical environments.

Q8: How is the power supplied to the module?

A8: It operates with a 24 V DC power supply and supports redundant power connections.

Q9: What happens if the primary processor fails?

A9: In redundant configurations, the secondary processor takes over instantly without process interruption.

Q10: Can the F8560X be integrated with third-party control systems?

A10: Yes, it can be integrated through standard industrial communication protocols.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...